Device and method for measuring size and roundness of tiny round hole at same time

A round hole, tiny technology, applied in the field of measurement of tiny round holes, can solve the problems of not being able to measure the roundness at the same time, difficult to accurately measure the size of the microhole, and unable to find the center point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

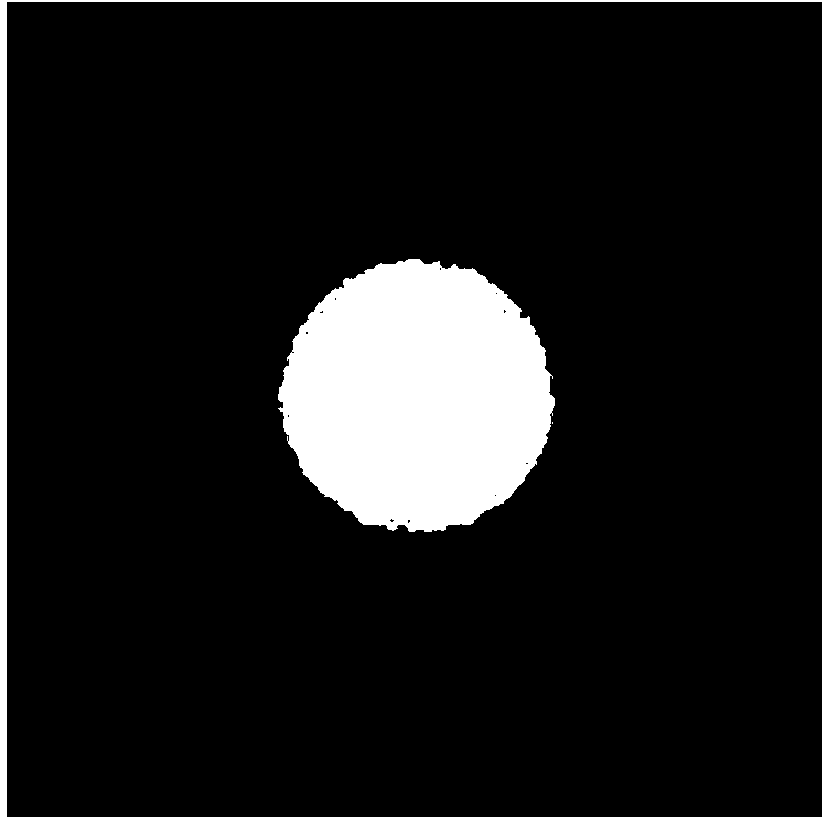

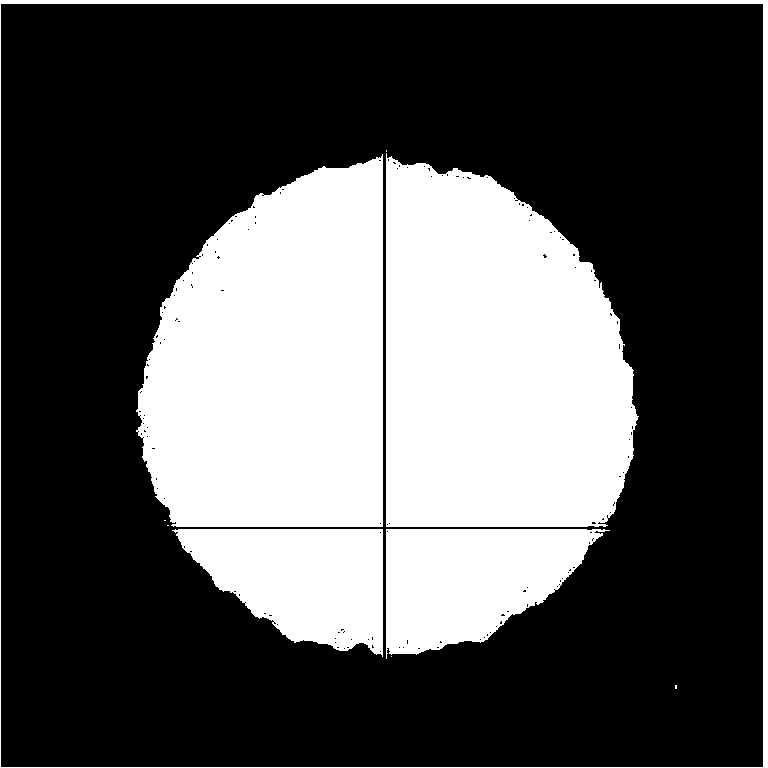

Image

Examples

Embodiment

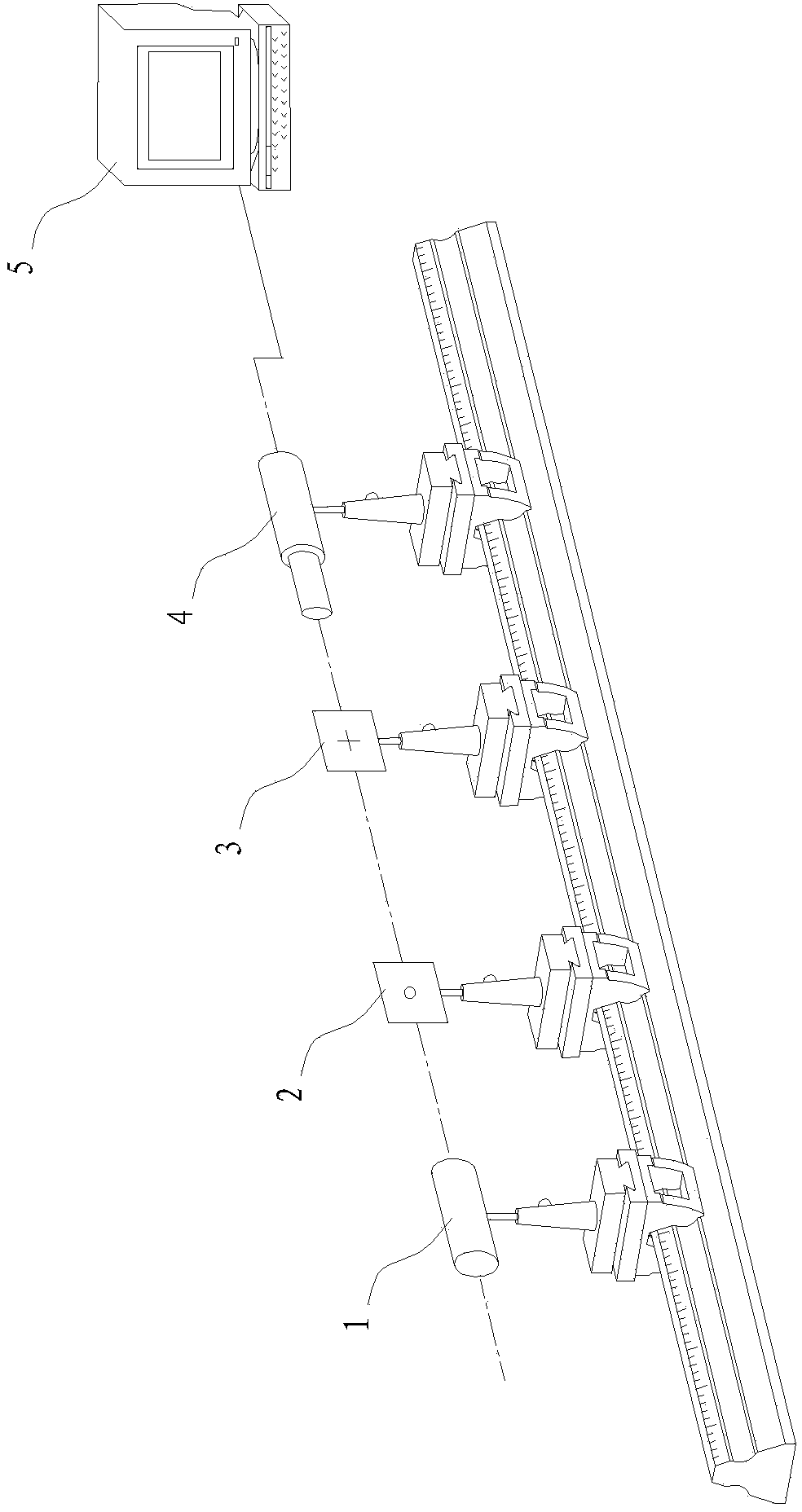

[0029] Example: see figure 1 , a device for simultaneously measuring the size and roundness of tiny circular holes, comprising a He-Ne laser 1, a circular hole to be measured and a holder 2, a frosted glass receiving screen with a mark 3, an information collection device 4, and an information processing device 5,

[0030] Among them, the He-Ne laser 1, the circular hole to be measured and the holder 2, the glass receiving screen 3 with the logo and the information collection device 4 are carried by the two-dimensional adjustable device and placed on the optical platform, in which the tiny circle to be measured is clamped. The hole is a precision two-dimensional adjustable device, through adjustment to ensure that their optical axis (or center) is basically on a straight line, the surface of the measured round hole, the holder and the glass receiving screen with the mark are parallel and perpendicular to the above-mentioned straight line, the data Through precise adjustment and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com