Implement method for water film thickness sensor based on bilinear interpolation algorithm

A technology of bilinear interpolation and water film thickness, which is applied to instruments, measuring devices, and using wave/particle radiation, etc., can solve problems such as temperature drift, large errors, and inability to obtain water film thickness calibration data, etc., to reduce measurement errors , performance improvement, fast calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

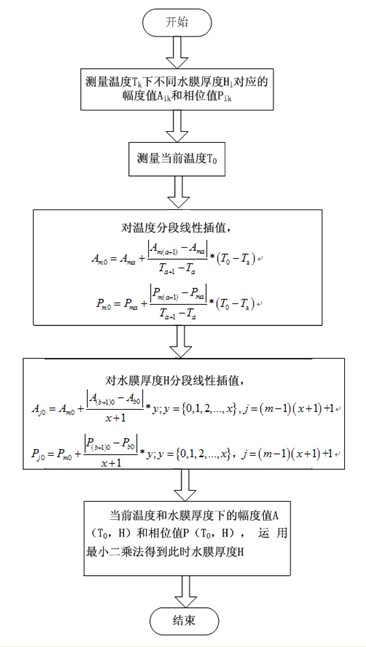

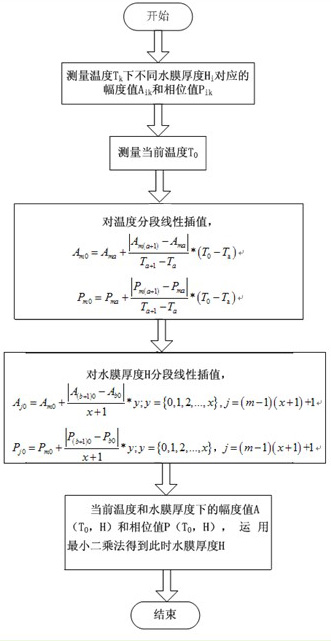

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] The implementation method of the water film thickness detection sensor based on the bilinear interpolation algorithm provided by the invention comprises the following steps:

[0029] Step a, measure different temperature T k Under different water film thickness H i Corresponding amplitude value A ik and the phase value P ik ,

[0030] Where k={1,2,…,n}, n represents the number of selected temperature values, the actual T k The value is determined according to the temperature measurement range; i={1,2,...,m}, m represents the number of selected water film thickness values, and the water film thickness H i The value is selected according to the measurement accuracy of water film thickness;

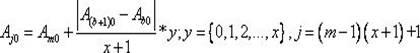

[0031] Step b. Measure the current temperature T 0 , and segmentally linearly interpolate the temperature to obtain the amplitude value A at the current temperature m0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com