Automatic checking device for pressure case assembly

A technology of automatic inspection and lateral movement, applied in the direction of measuring devices, instruments, etc., can solve the problem of many errors, achieve the effect of high efficiency, improve accuracy, and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

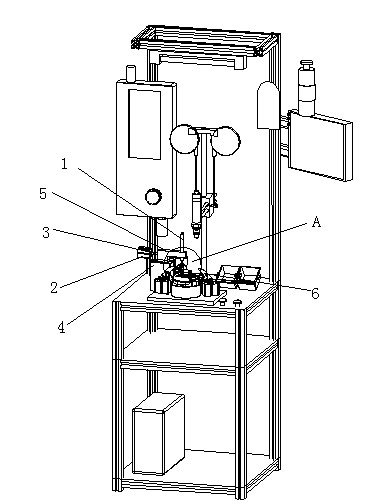

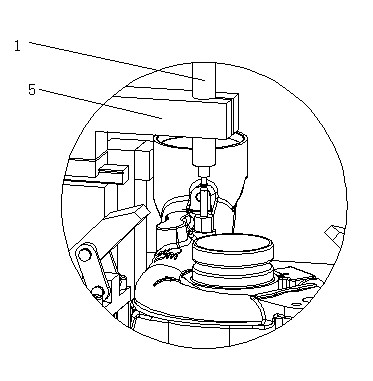

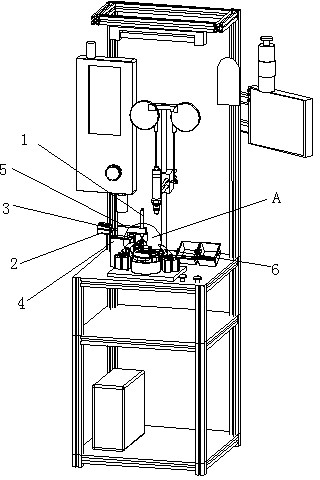

[0014] Embodiment: An automatic inspection device for pressing shell assembly. After the gas nozzle and gasket of the pressing shell are assembled on the workbench, the assembly effect needs to be checked. A displacement sensor 1 is provided. Based on the use direction, the displacement sensor is driven Under the action of the structure, lateral movement can be made (thus the position of the displacement sensor 1 can be adjusted to be coaxial with the gas nozzle), and the displacement sensor can automatically detect the installation height of the gas nozzle.

[0015] The displacement sensor 1 is not in contact with the air nozzle in the axial direction. Based on the use direction, the detected installation height of the air nozzle is: the axial dimension value of the upper end of the air nozzle and the lower end of the displacement sensor. When the size is within the error range, the average For qualified products.

[0016] The structure that the displacement sensor 1 can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com