Clamp

A fixture and main body technology, applied in the field of circuit board online program writing auxiliary fixture, can solve the problems of inability to observe voltage online, low operation efficiency, unsafe, etc., to improve production efficiency and operation reliability, meet process technical requirements, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

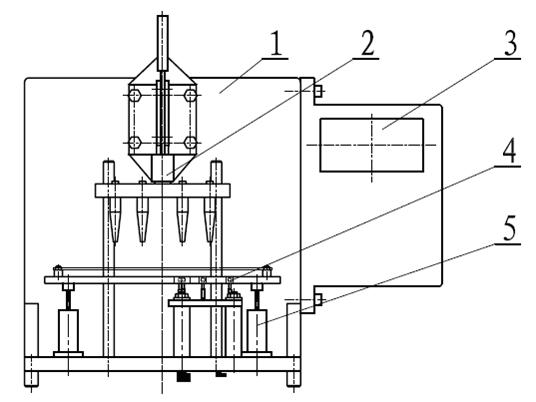

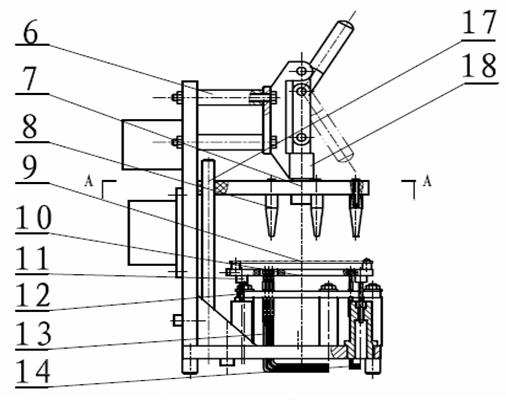

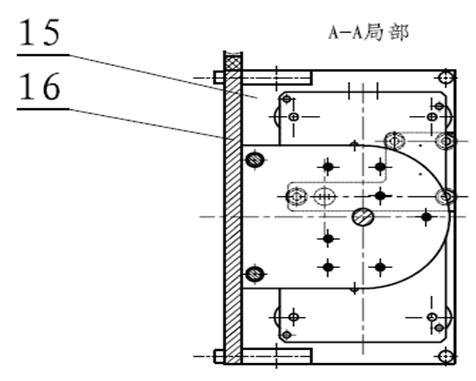

[0017] Such as Figure 1 to Figure 4 shown. The fixture of the present invention is composed of a fixture main body 1 , a pressing mechanism assembly 2 , a voltage display assembly 3 , a probe wire harness assembly 4 , and a PCB positioning mechanism assembly 5 . Wherein, the fixture main body 1 is a fixture body assembled from machined parts, and is used for installing and fixing various parts and components of the fixture. The bottom plate 15 and the back plate 16 are processed into an L-shaped aluminum alloy material, and the structure is simple. The pressing mechanism assembly 2 is arranged on the top of the backboard 16, and is composed of a guide slide bar 17, a press support 8 and a manual press pliers 18. The manual press pliers 18 are fixed on the backboard 16 by four fixing columns 6, and the guide slide bar 17 is longitudinally fixed on the base plate 15, and the pressing support 8 is evenly arranged on the pressing support fixing plate 7, and the pressing supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com