Transparent touch pad and method for manufacturing same

A manufacturing method and technology of a touch panel, applied to instruments, electrical digital data processing, input/output process of data processing, etc., can solve problems such as high manufacturing cost, consuming material cost, and affecting the visible area of the touch panel. To facilitate processing and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

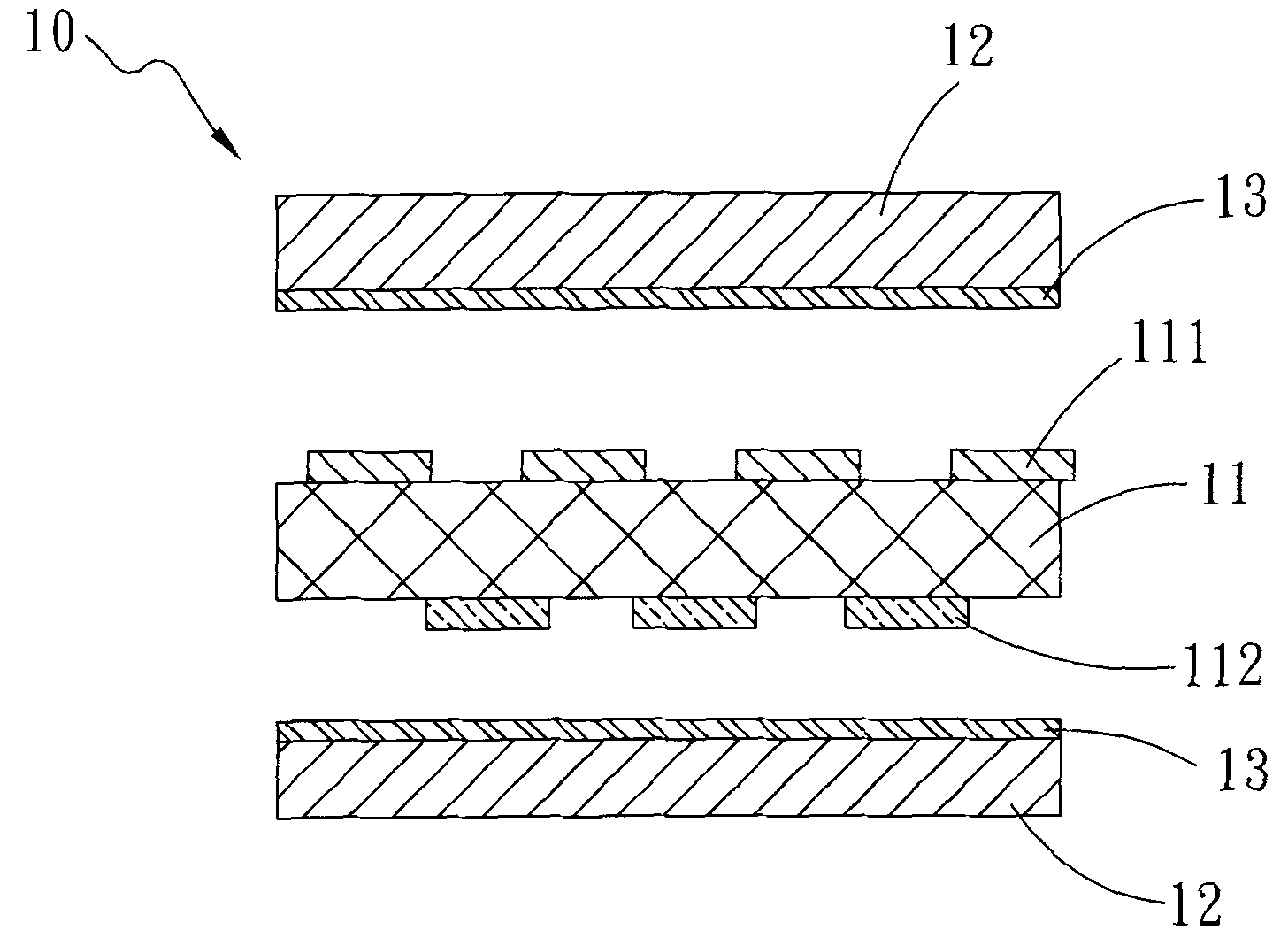

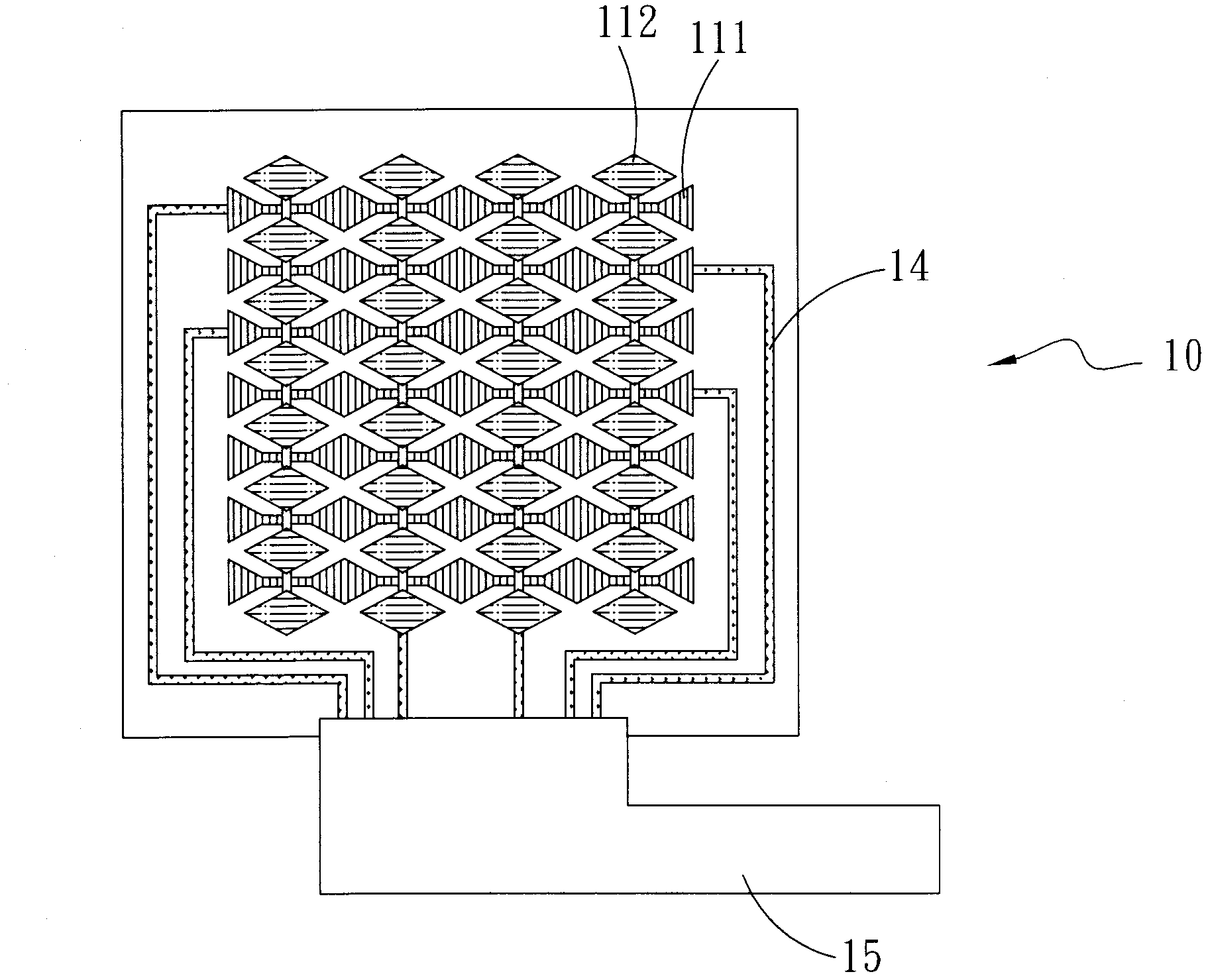

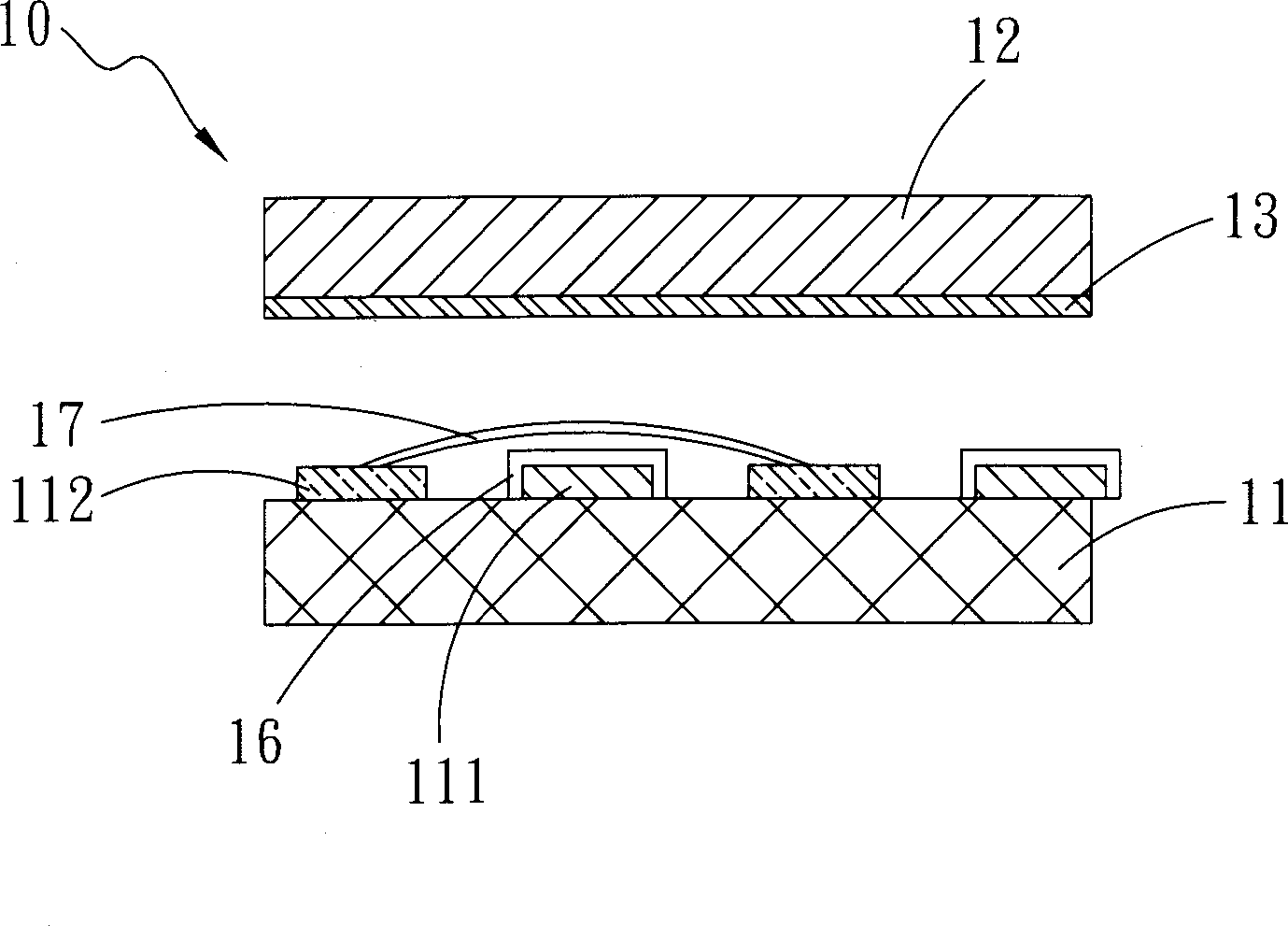

[0052] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the attached drawings.

[0053] see image 3 and Figure 4 As shown, it is a schematic diagram of the implementation of a preferred embodiment of the present invention. The light-transmitting touch panel 30 of the present invention includes a first light-transmitting substrate 40, a second light-transmitting substrate 50 and a bonding layer 60. The first light-transmitting The substrate 40 is a glass substrate or a PMMA (acrylic) substrate, and one side of the first transparent substrate 40 has a first surface 41 on which a plurality of first induction conductors 411 are covered. An inductive conductor 411 is electrically connected to each other along a first direction (horizontal direction) to form a plurality of first conductor groups 412, at least one end of each first conductor group 412 is connected to a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com