Optically diffusive adhesive and method of making the same

A technology of adhesives and light diffusion, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve problems such as errors, and achieve the effect of changing transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0083] All parts, percentages, ratios, etc. in the examples and in the remainder of the specification are by weight unless otherwise indicated.

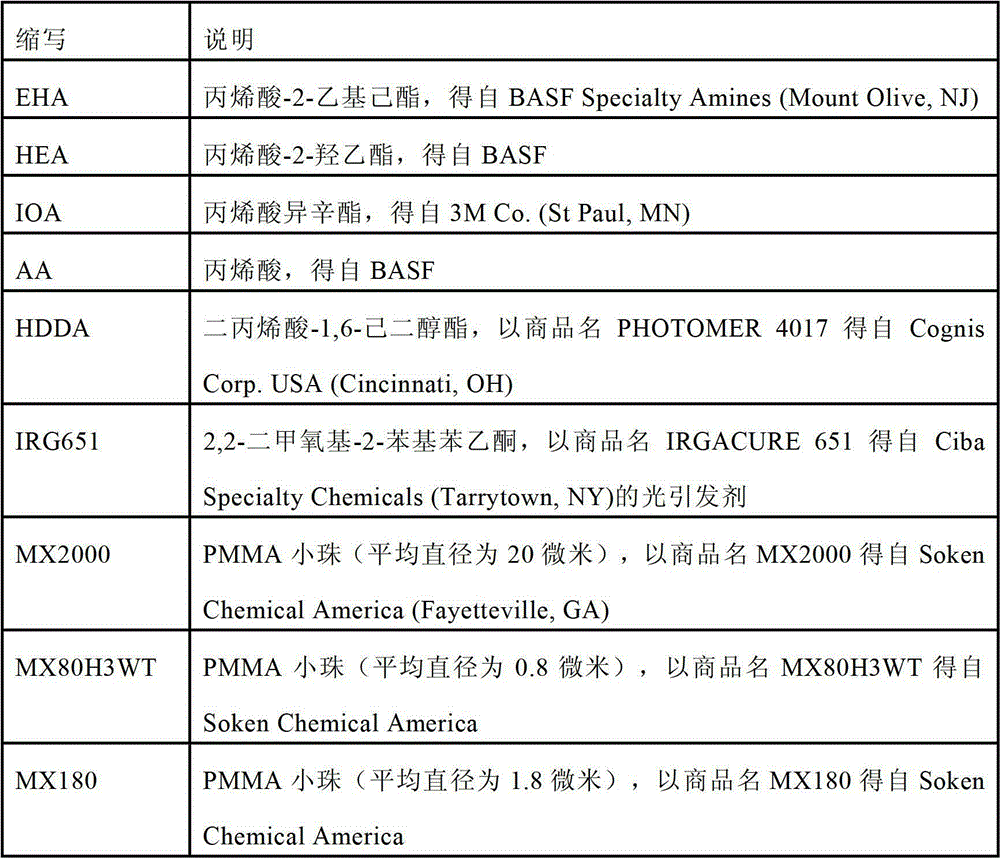

[0084] Acronym

[0085]

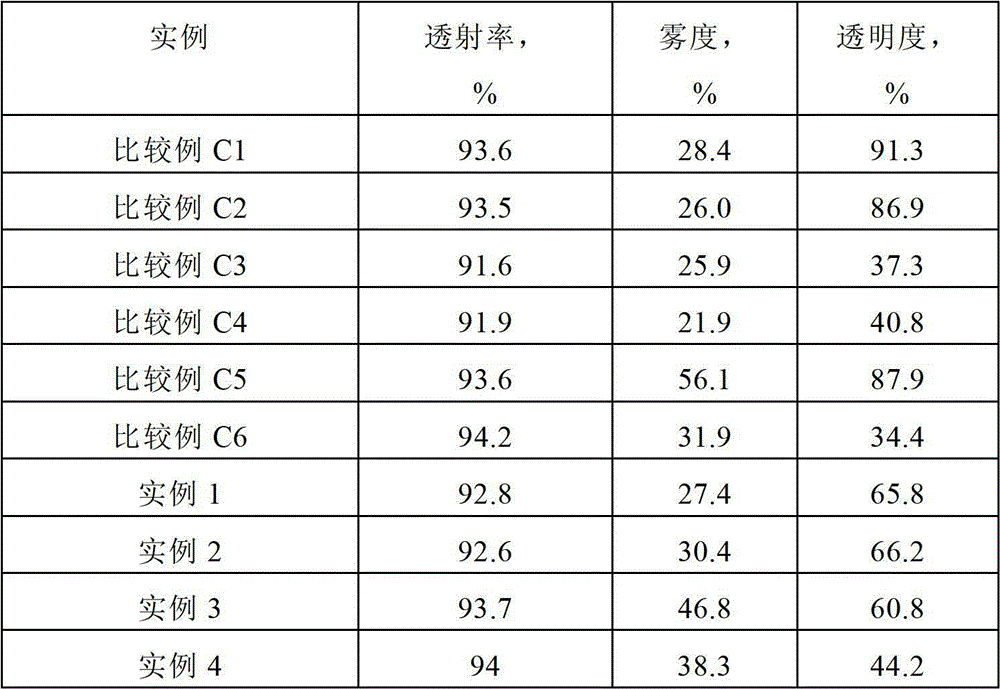

[0086] Light transmission and haze and clarity testing

[0087] Adhesive samples to be tested were prepared by transferring the adhesive from a release liner to a glass microscope slide.

[0088] Light transmission, haze, and clarity were measured using a HAZEGARD PLUS haze meter from BYK-Gardner Inc. (Silver Springs, MD).

preparation example 1

[0090] A monomer premix was prepared by mixing IOA (96 parts), AA (4 parts) and IRG651 (0.04 parts). The mixture was purged with nitrogen for at least 10 minutes. The mixture is then partially polymerized by exposing it to ultraviolet radiation under a nitrogen-enriched atmosphere, resulting in a coatable slurry having a viscosity of about 500-3000 cP (0.5-3 Pa-sec). To 200 grams (g) of this slurry was added 6.54 g AA, 36.36 g HEA, 4.4 g of a 10% solution of Irg651 in EHA, and 1.6 g of a 10% solution of HDDA in EHA prior to use. Mix well.

preparation example 2

[0092] A monomer premix was prepared using EHA (96 parts), HEA (4 parts) and photoinitiator IRG651 (0.04 parts). The mixture was purged with nitrogen for at least 10 minutes. The mixture is then partially polymerized by exposing it to ultraviolet radiation under a nitrogen-enriched atmosphere, resulting in a coatable slurry having a viscosity of about 500-3000 cP (0.5-3 Pa-sec). To 200 g of this slurry was added 6.55 g of AA, 36.36 g of HEA, 0.44 g of IRG651 and 1.6 g of a 10% solution of HDDA in EHA and then mixed well before use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com