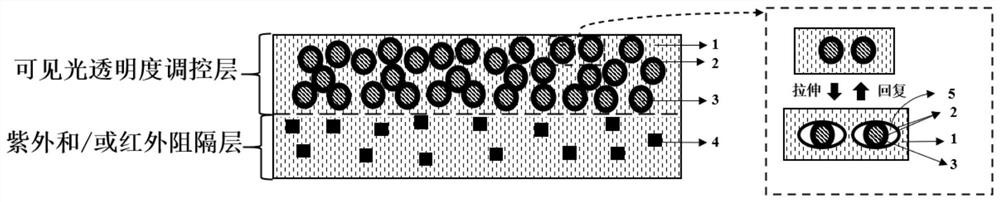

A highly sensitive mechanically regulated smart window film and its preparation method

A smart window and mechanical technology, applied in the field of smart windows, can solve the problems of lack of multi-band control ability, low binding force, low optical adjustment sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

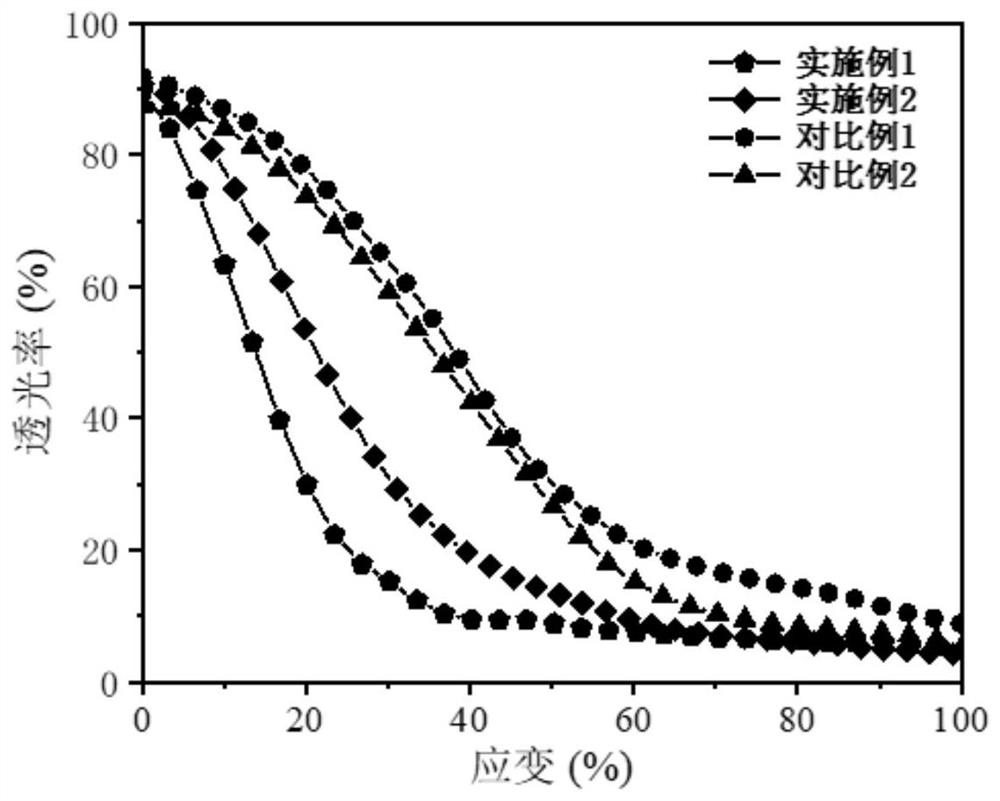

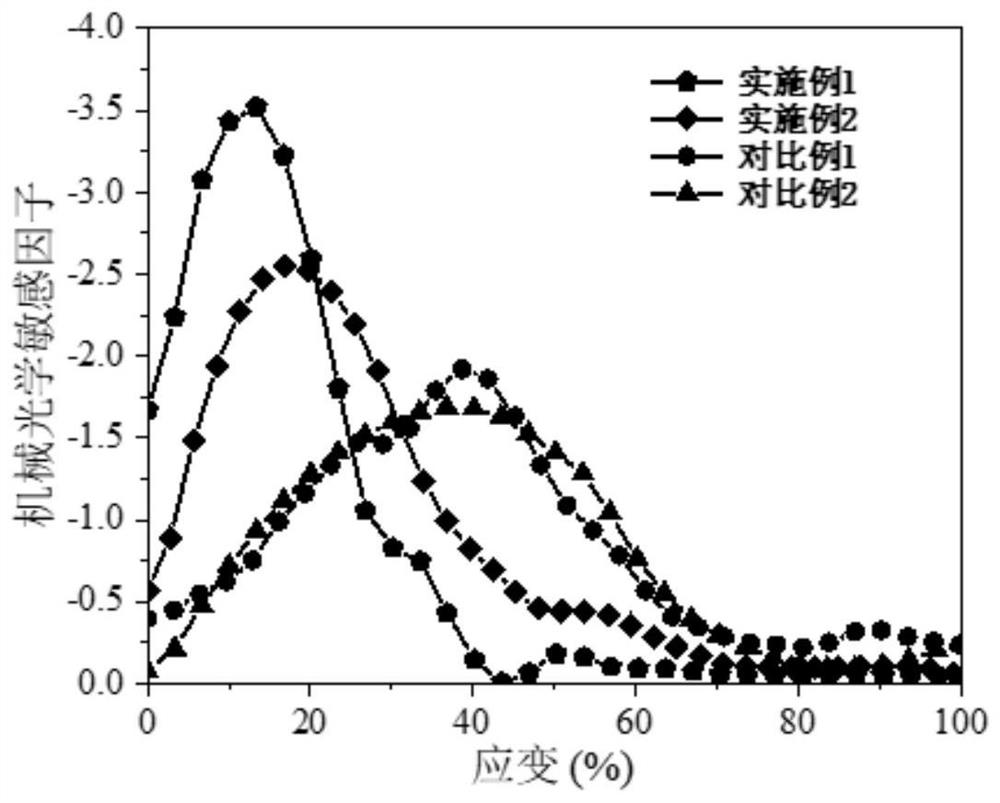

Embodiment 1

[0055] A method for preparing a highly sensitive mechanically regulated smart window film, the steps are as follows:

[0056] (1) Preparation of SiO 2 Nano microsphere dispersion liquid and dispersion blue E-4R low binding force molecular material solution;

[0057] SiO with an average particle size of 300 nm was added at a concentration of 10 mg / mL 2 The nanospheres were dispersed in isopropanol, and evenly dispersed SiO 2 Nano microsphere dispersion;

[0058] Dissolve the disperse blue E-4R low-binding molecular material in acetone at a concentration of 1 mg / mL, and after ultrasonication for 30 minutes, prepare the disperse blue E-4R low-binding molecular material solution;

[0059] (2) Two-step spraying;

[0060] SiO 2 The nano-microsphere dispersion is loaded into the Master spray gun (spray gun model G44) and sprayed 10 times on the substrate with a spraying pressure of 50KPa, a spraying distance of 5cm and a moving speed of 5cm / s, and then disperse blue E-4R low bin...

Embodiment 2

[0077] A method for preparing a highly sensitive mechanically regulated smart window film, the steps are as follows:

[0078] (1) Preparation of SiO 2 Nano microsphere dispersion and Sudan II low binding force molecular material solution;

[0079] SiO with an average particle size of 300 nm was added at a concentration of 10 mg / mL 2 The nanospheres were dispersed in isopropanol, and evenly dispersed SiO was prepared after strong ultrasonication for 45 minutes 2 Nano microsphere dispersion;

[0080] Dissolve the Sudan II low-binding molecular material in ethanol at a concentration of 1 mg / mL, and after strong ultrasonication for 45 minutes, prepare a Sudan II low-binding molecular material solution;

[0081] (2) Two-step spraying;

[0082] SiO 2 The nano-microsphere dispersion is loaded into the Master spray gun (spray gun model G44) and sprayed 10 times on the substrate with a spraying pressure of 50KPa, a spraying distance of 5cm and a moving speed of 5cm / s, and then the...

Embodiment 3

[0099] A method for preparing a highly sensitive mechanically regulated smart window film, the steps are as follows:

[0100] (1) Preparation of SiO 2 Nano microsphere dispersion liquid and dispersion blue E-4R low binding force molecular material solution;

[0101] SiO with an average particle size of 300 nm was added at a concentration of 10 mg / mL 2 The nanospheres were dispersed in isopropanol, and evenly dispersed SiO was prepared after strong ultrasonication for 40 minutes 2 Nano microsphere dispersion;

[0102] Dissolve the Disperse Blue E-4R low-binding molecular material in acetone at a concentration of 1 mg / mL, and after 40 minutes of strong ultrasonication, prepare the Disperse Blue E-4R low-binding molecular material solution;

[0103] (2) Two-step spraying;

[0104] SiO 2 The nano-microsphere dispersion is loaded into the Master spray gun (spray gun model G44) and sprayed 10 times on the substrate with a spraying pressure of 50KPa, a spraying distance of 5cm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com