Automatic capping heat-preserving system for molten steel bottles or hot-metal bottles

A heat preservation system and molten iron tank technology, applied in metal processing equipment, casting melt container, casting equipment, etc., can solve the problems of cumbersome operation, low reliability, complex system structure, etc., achieve simple operation, ensure production efficiency, heat preservation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

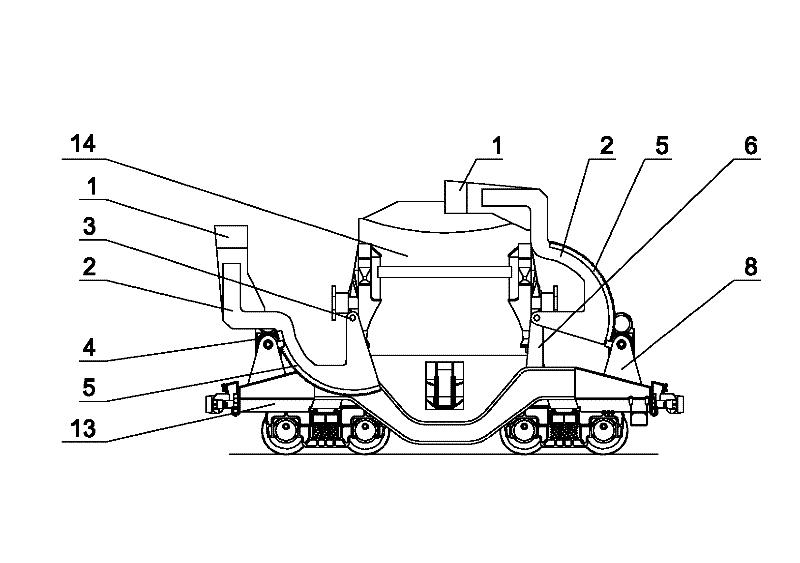

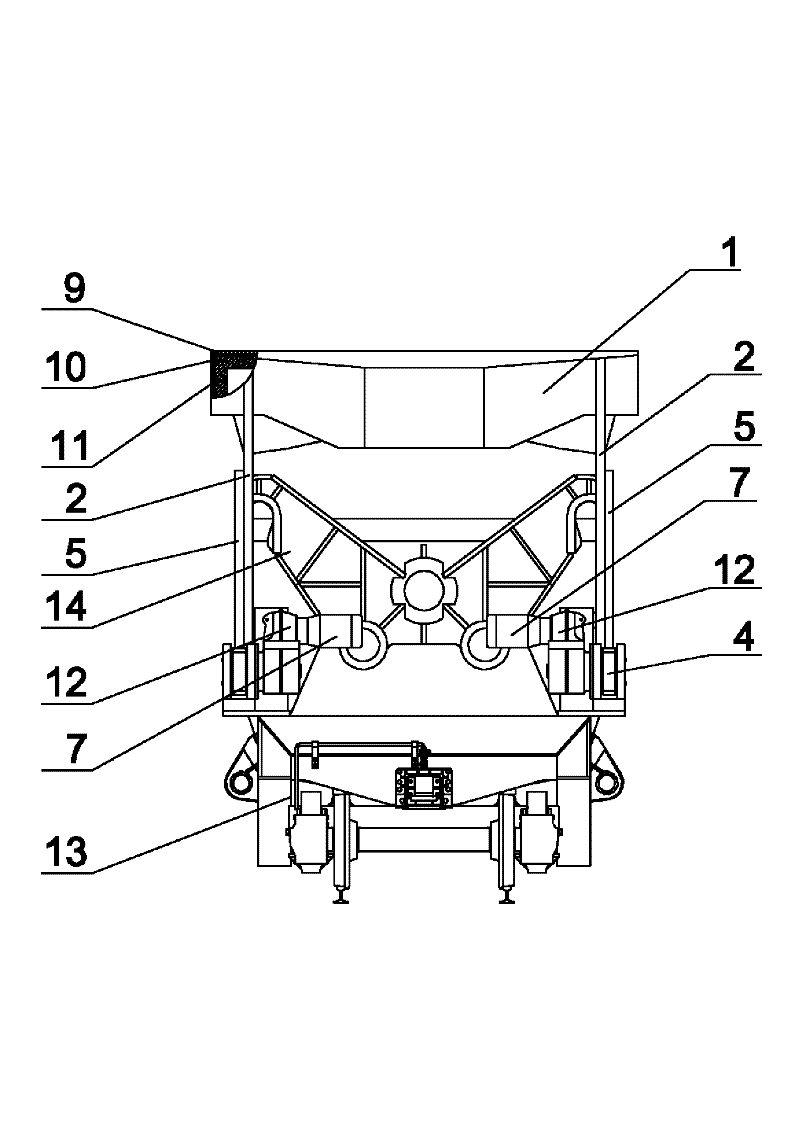

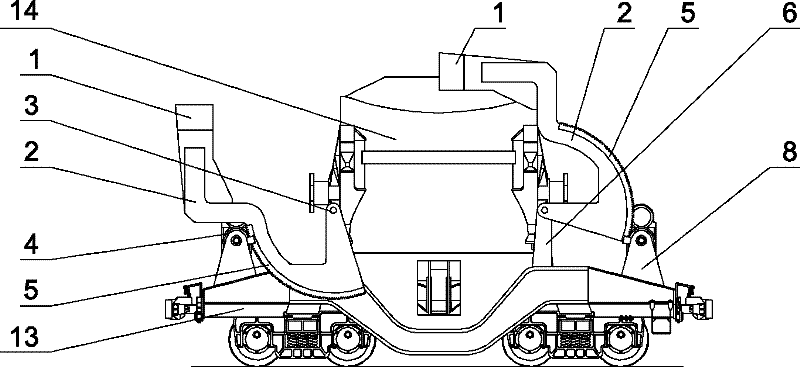

[0013] See figure 1 , the molten steel tank or the molten iron tank 14 is placed on the tank seat of the metallurgical transport tanker 13, the automatic capping and heat preservation system of the present invention is integrally installed on the metallurgical transport tanker 13, and the automatic capping and heat preservation system includes two split heat preservation covers 1, two The split-type thermal insulation cover 1 is symmetrically installed on the lateral sides of the tank base of the metallurgical transport tanker 13 through the opening and closing mechanism, and is combined and opened above the tank mouth of the molten steel tank or the molten iron tank 14 through the opening and closing mechanism; the opening and closing mechanism includes Insulation cover installation frame 2, insulation cover opening and closing drive mechanism and insulation cover opening and closing transmission mechanism, the split type insulation cover 1 is fixed to the insulation cover ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com