High-temperature-resistance abrasion-resistance nanometer bearing fan

A wear-resistant and high-temperature-resistant technology, applied in coatings, liquid fuel engines, mechanical equipment, etc., can solve problems such as increased noise, violent vibration of fans, and bearing wear, achieving strong high-temperature resistance, prolonging service life, non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a further description of the high-temperature-resistant and wear-resistant nano-bearing fan described in the application of the present invention in conjunction with the accompanying drawings. On the basis of the same or similar principles, the improvement of the fan, including its shape, size, material used, and the increase, decrease or replacement of corresponding parts, in order to achieve basically the same technical effect, are all included in this Within the technical solution claimed in the invention application.

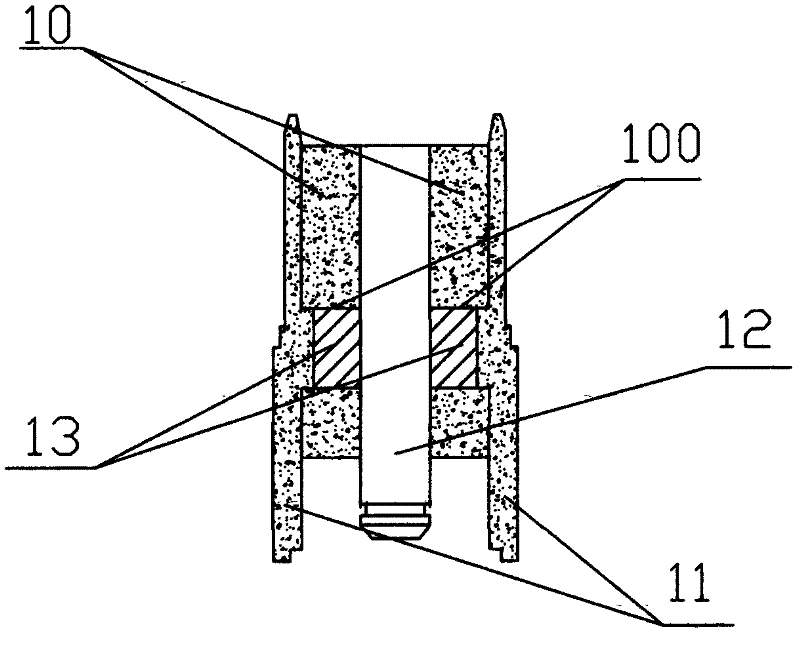

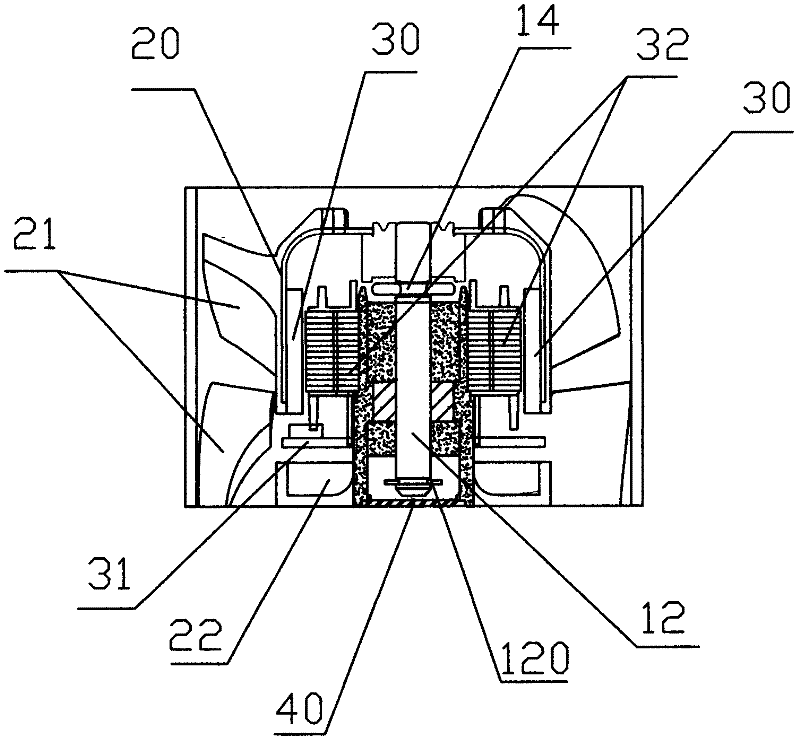

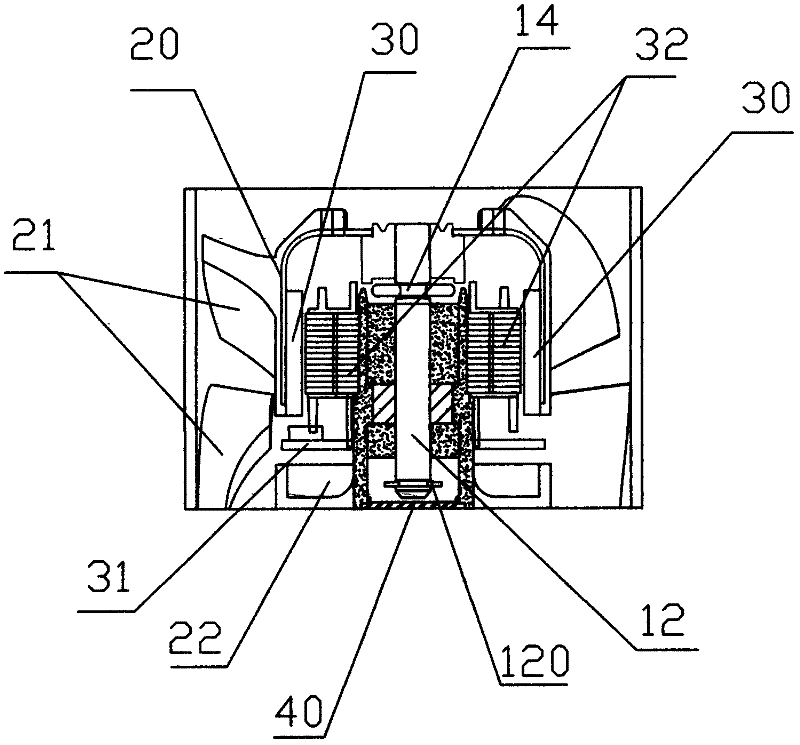

[0020] like figure 1 As shown, the high-temperature-resistant and wear-resistant nano-bearing fan described in the application of the present invention is a bearing made of nano-materials, including an outer ring 11 and an inner ring 10, wherein the inner ring 10 is a discontinuous upper and lower ring structure, the middle part is a housing cavity 100, the housing cavity 100 is provided with oil storage cotton 13, the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com