Synthesis method of lithium iron phosphate lithium ion battery cathode material

A lithium-ion battery and lithium iron phosphate technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor slurry uniformity, easy agglomeration of materials, and large surface energy, so as to improve processing performance, ensure electrical conductivity, Carbon reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

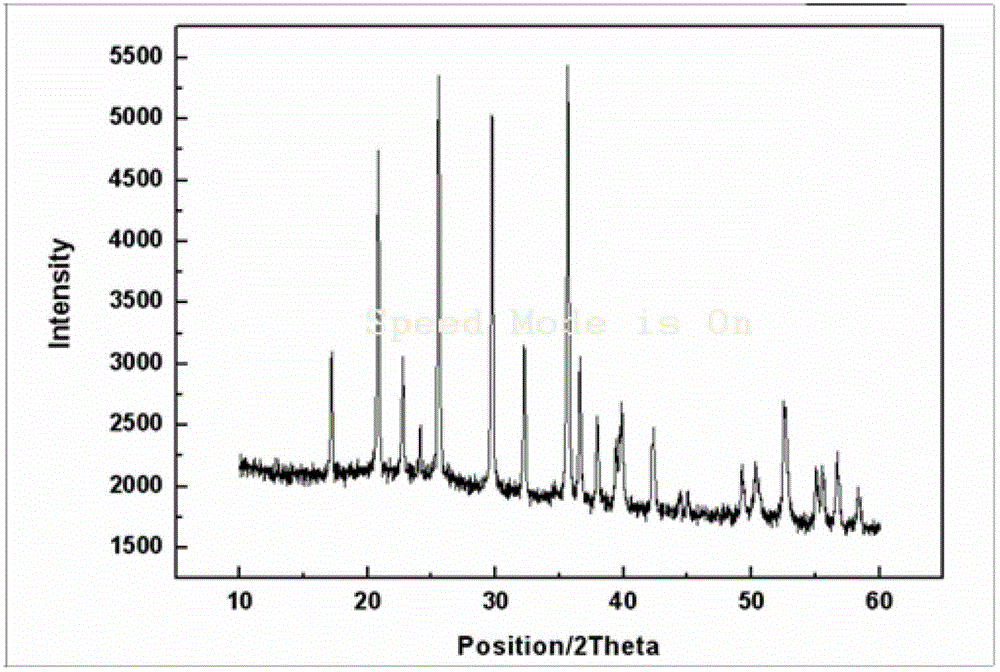

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. In the present invention, "carbon utilization rate" is defined as: the contribution of the unit carbon content in the lithium iron phosphate material to the electronic conductance, or the improvement of the conductance by each percentage point of carbon mass, carbon utilization rate = conductivity ÷ carbon content, conductivity unit S / cm, carbon content is the mass percentage of carbon in the material C%.

[0020] The synthetic method of lithium iron phosphate lithium ion battery cathode material of the present invention comprises the following steps:

[0021] One, synthetic precursor, with lithium source compound, iron source compound, phosphorus source compound, organic carbon source as raw material, lithium source compound, iron source compound, phosphorus source compound according to the molar ratio of lithium, iron, phosphorus element in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap