Compression spring type electric power grounding line operation rod

A technology of compressing springs and grounding wires, applied in the direction of connection/disconnection of overhead lines/cable equipment, connecting devices, etc. Difficulty and other problems, to achieve the effect of convenient operation, broad promotion and application prospects, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

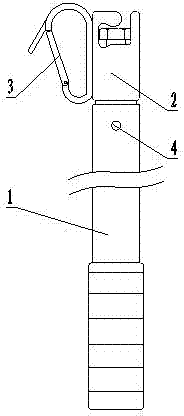

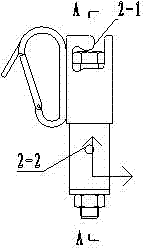

[0017] See Figure 1, Figure 2, image 3 , the present invention includes a rod head 2 and a rod body 1, the lower part of the rod head 2 is sleeved inside the rod body 1, and fixedly assembled with the rod body 1 by the rod head fixing screw 4, and fixedly installed on the outer wall of the upper half of the rod head 2 The spring-type closed ring hook 3 is provided with an automatic detachment mechanism for the grounding wire conductor end inside the rod head 2 .

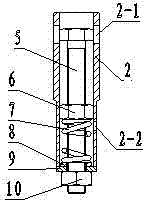

[0018] See Figure 3, Image 6 , the automatic detachment mechanism of the ground wire conductor end of the present invention is composed of a bolt 5, a spring compression nut 6, a compression spring 7, an elastic washer 8, a flat washer 9 and a fixing nut 10, and the spring compression nut 6 is fixedly set on the bolt 5 In the middle part, the compression spring 7 is set on the outside of the bolt 5, it is arranged between the spring compression nut 6 and the elastic washer 8, the flat washer 9 is fixed at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com