Method for recovering energy when compressing a gas with a compressor

A technology for compressing gases and compressors, applied in the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. Sufficient, reduced calcification risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

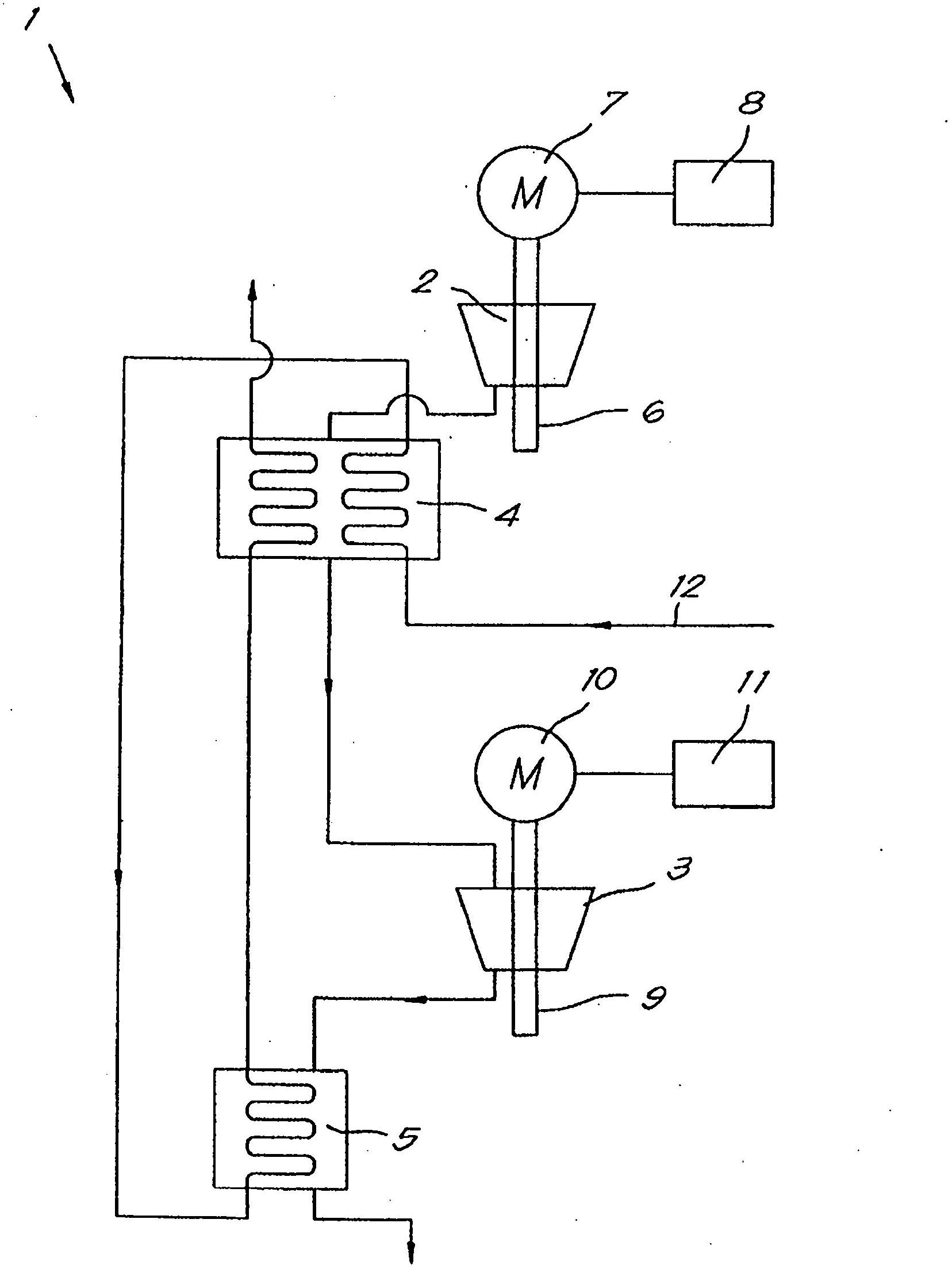

[0037] figure 1 A compressor 1 for compressing a gas such as air is shown, in this case having two compression stages connected in series. Each compression stage is realized by a turbo compressor head, that is, a low-pressure compressor head 2 and a high-pressure compressor head 3 respectively.

[0038] In this particular example, the outlet temperature of the first low-pressure compressor block 2 is higher than the outlet temperature of the second high-pressure compressor block 3 .

[0039] In this case, heat exchangers are arranged downstream of each compressor head 2 and 3, specifically, the first heat exchanger 4 or intercooler is arranged downstream of the low-pressure compressor head 2, and the second heat exchanger The cooler 5 or aftercooler is arranged downstream of the high pressure compressor head 3 .

[0040] The low-pressure compressor head 2 is connected to a first shaft 6 driven by a first motor 7 equipped with a motor control 8 .

[0041] The high-pressure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com