Sowing method capable of controlling extending directions of corn leaves

A leaf extension, corn technology, applied in the agricultural field, can solve the problems of decreased yield, weakened photosynthetic efficiency, insufficient individual light, etc., and achieves the effects of increasing density, improving randomness, and improving unit yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

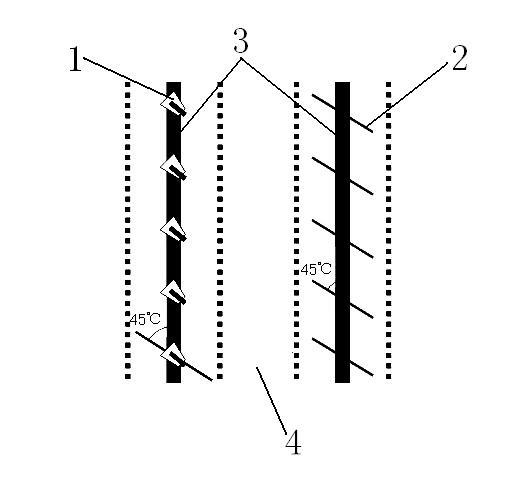

[0015] see figure 1 , artificial sowing, the flat surface of the seed is on a nearly horizontal plane, the endosperm is upward, the connecting line between the tip of the seed and the midpoint of the long axis of the top (or the longitudinal section of the seed embryo) and the small angle between the ridge (or row) and the ridge (or row) are at 45 °C, and grow out. The small angle between the leaf extension direction of the plant and the ridge (or row) is 45°C. figure 1 The serial number 1 is the seed, the serial number 2 is the leaf, the serial number 3 is the ridge platform, and the serial number 4 is the ridge and furrow.

Embodiment 2

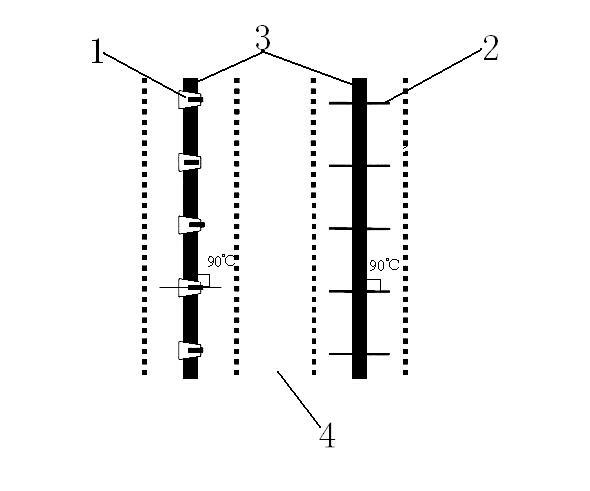

[0017] see figure 2 , artificial sowing, the flat surface of the seed is on a nearly horizontal plane, the endosperm is upward, the connection line between the tip of the seed and the middle point of the long axis of the top (or the longitudinal section of the seed embryo) and the angle between the ridge (or row) and the ridge (or row) are at 90 ° C, and grow out. The angle between the leaf extension direction and the ridge (or row) of the plants is 90°C. figure 2 The serial number 1 is the seed, the serial number 2 is the leaf, the serial number 3 is the ridge platform, and the serial number 4 is the ridge and furrow.

Embodiment 3

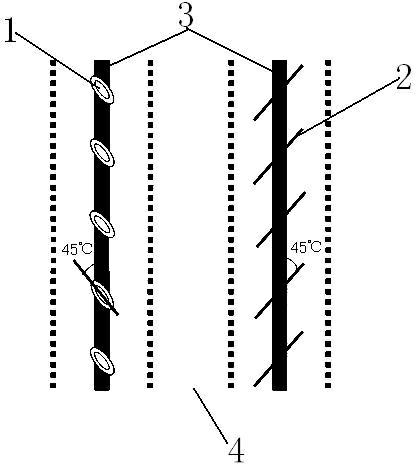

[0019] see image 3 , artificial sowing, the tip of the seed is vertically downward, the top is upward, the small angle between the long axis (or flat surface) of the top of the seed and the ridge (or row) is 45°C, and the leaf extension direction of the grown plant is the same as that of the ridge (or row). ) at an angle of 45°C. image 3 Among them, the serial number 1 is the seed, the serial number 2 is the leaf, the serial number 3 is the ridge platform, and the serial number 4 is the furrow.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap