A field waste film removal machine

A clearing machine and field technology, applied in the field of agricultural machinery, can solve the problems that threaten the sustainable development of agriculture, reduce the utilization rate of arable land, and difficult to replant, and achieve the effect of improving the yield per unit of crops, high mulching film recovery rate, and increasing farmers' income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

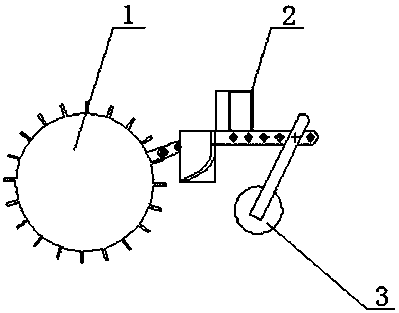

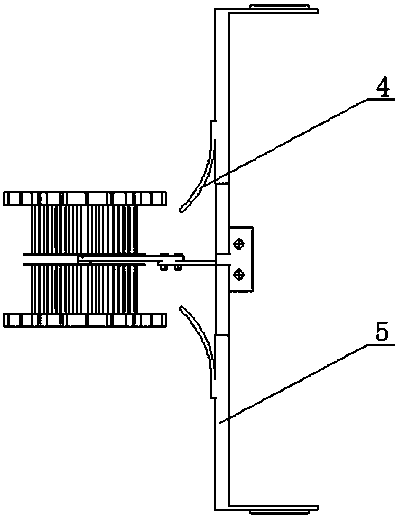

[0015] as attached Figure 1-2 As shown, a field waste film removal machine includes a frame 6, the two ends of the frame 6 are connected with the film cutting wheel arm 5, and the end of the film cutting wheel arm 5 away from the frame 6 is connected with the film cutting wheel 3, and the film cutting wheel arm 5 is connected with the film cutting wheel 3. The wheel arm 5 is provided with a guide plate 4 near one end of the frame 6, and the middle part of the frame 6 is connected with the peeling wheel 1, and the frame 6 is also provided with a connecting frame 2 for connecting with the power system.

[0016] The film cutting wheel arm 5 is a telescopic arm.

[0017] One end of the film-cutting wheel arm 5 close to the frame 6 is provided with a top wire mechanism for fixing the film-cutting wheel arm 5. When it is necessary to adjust the distance between the film-cutting wheels 3, first loosen the top wire and move along the The frame 6 moves the film-cutting wheel arm 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com