Containing device and manufacturing method thereof

A technology of a storage device and a manufacturing method, which can be applied to other household appliances, clothing, luggage, etc., can solve the problems that the structure can no longer be processed and decorated, the appearance is not good, and the flatness is affected, so as to increase the sense of design and beauty. , Increase the beauty and decoration, the effect of easy flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

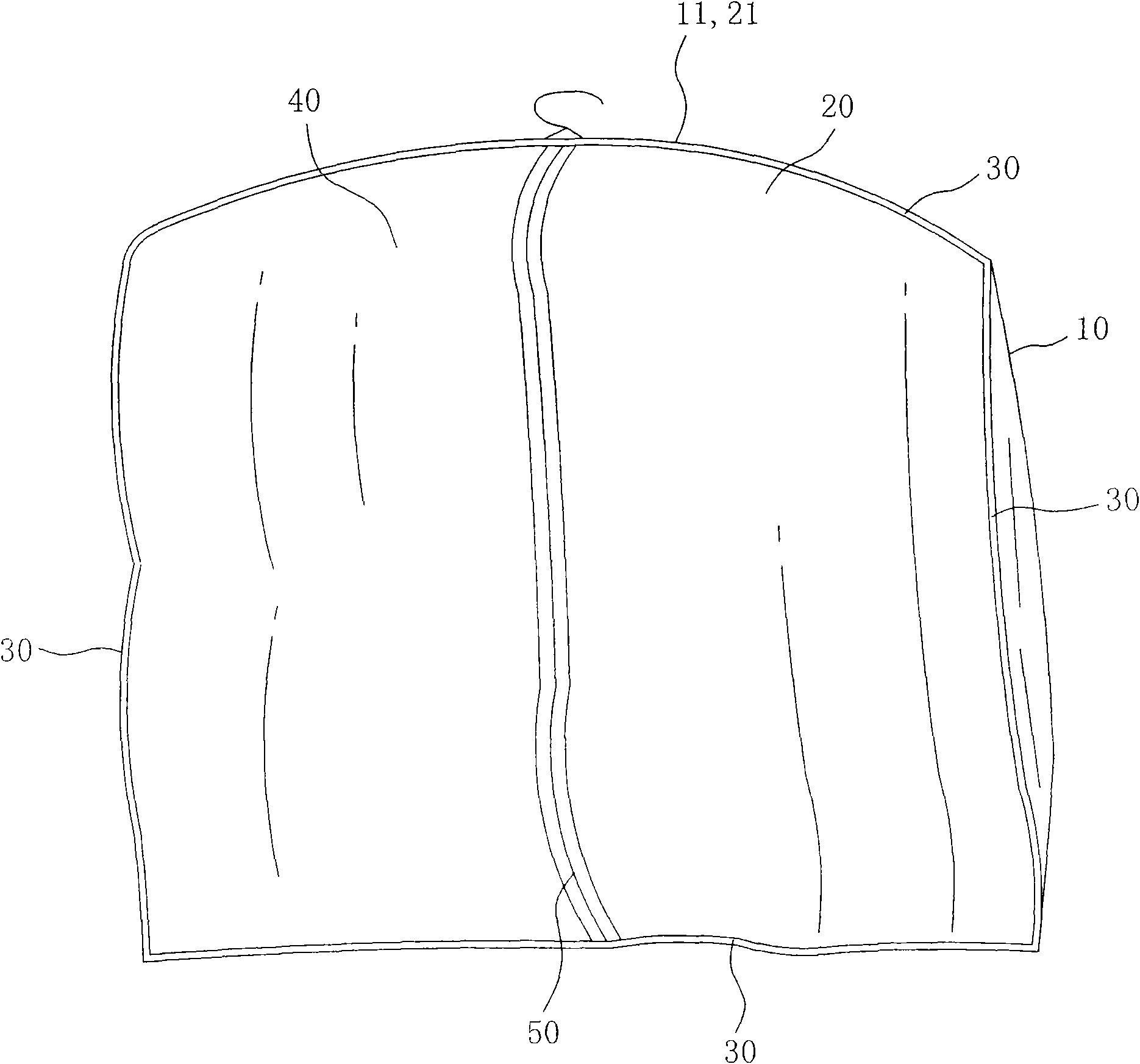

[0050] Please refer to figure 1 As shown, taking a garment cover as an example, the second cloth sheet 20 is stacked on the first cloth sheet 10, and the peripheral edge 11 of the first cloth sheet 10 and the peripheral edge 21 of the second cloth sheet 20 are aligned. , and implement ultrasonic welding on the periphery 11, 21 (welding portion 101, 201), so that the first cloth piece 10 and the second cloth piece 20 are ultrasonically welded together, and on the first cloth piece 10 The receiving space 40 is formed between the second cloth sheet 20 , and a zipper 50 is further provided in the middle of the second cloth sheet 20 for opening and closing the receiving space 40 .

Embodiment 2

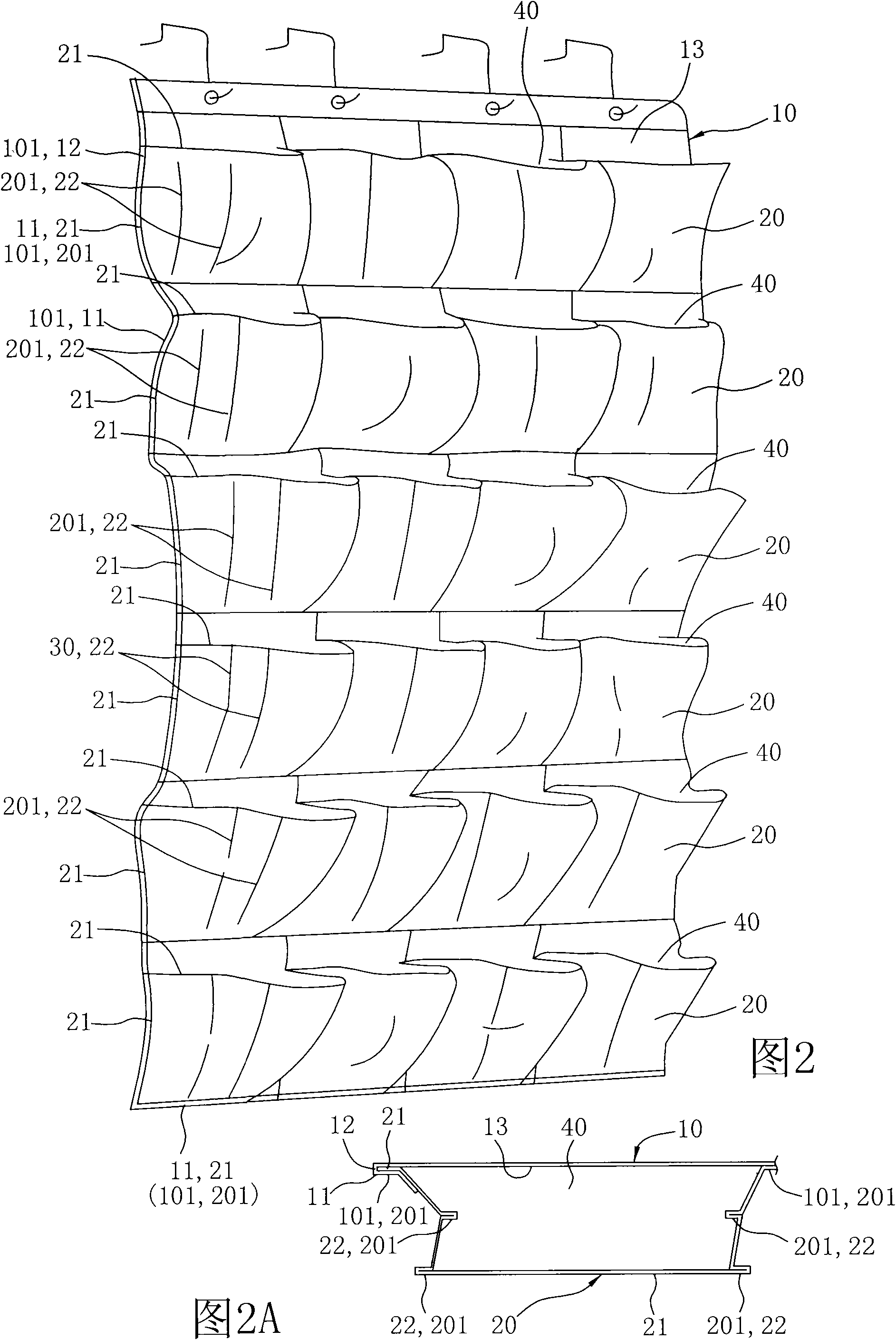

[0052] Please refer to figure 2 and Figure 2A As shown, taking a multi-compartment hanging bag as an example, a first cloth sheet 10 of an appropriate shape and size is provided, and several second cloth sheets 20 are stacked on one side of the first cloth sheet 10 from top to bottom. 13, and align the left and right sides of the first piece of cloth 10 and the peripheral edges 11, 21 of these second pieces of cloth 20, and align the left and right sides of the first piece of cloth 10 and the second pieces of cloth 20 Surroundings 11, 21 (welding portions 101, 201) are ultrasonically welded, so that the left, right, and lower edges of the second cloth sheets 20 are welded and fixed on the side surfaces 13 of the first cloth sheet 10. Ultrasonic welding is further implemented at appropriate positions on the front of these second cloth sheets 20 at intervals, so that several storage spaces 40 are separated between the first cloth sheet 10 and the second cloth sheets 20, as sh...

Embodiment 3

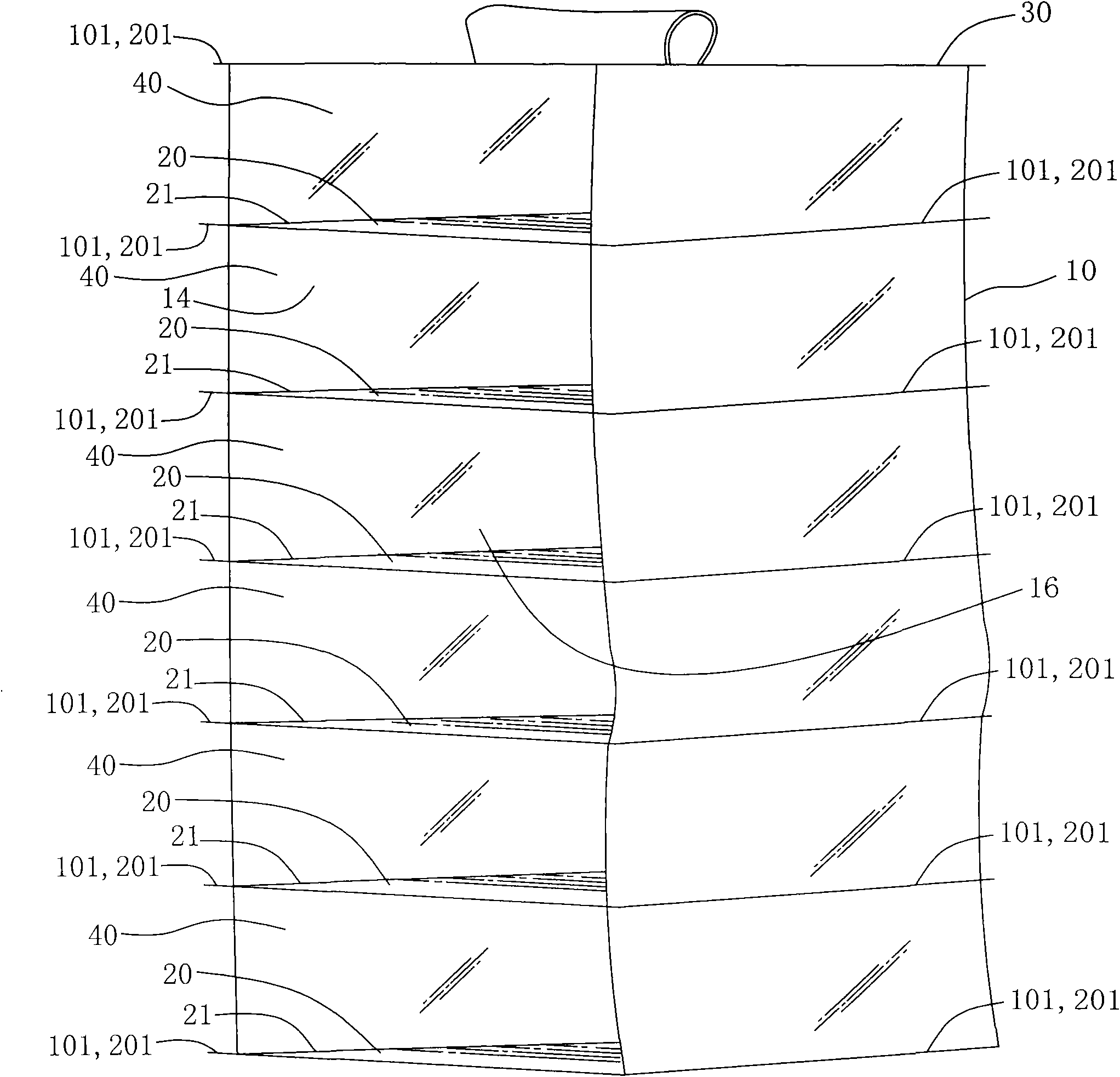

[0054] Please refer to image 3 and Figure 3A As shown, taking a multi-compartment wardrobe as an example, a first piece of cloth 10 is prefabricated into a "ㄈ" shape, so that its appearance shows that the upper, lower, and front ends are open, and a rectangular space 16 is formed inside. Rectangular second cloth pieces 20 are arranged at intervals from the upper end to the lower end on the rectangular space 16 preset by the at least one first cloth piece 10 , and the left and right sides of the periphery 21 of the second cloth pieces 20 are arranged and the rear side and the inner side 14 of the corresponding first cloth sheet 10 are ultrasonically welded, so that the welding parts 101, 201 of the first cloth sheet 10 and the second cloth sheets 20 are ultrasonically welded together , and an appropriate number of storage spaces 40 are separated between the first cloth sheet 10 and the second cloth sheets 20, such as image 3 As shown, the number of the storage spaces 40 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com