Extrusion casting die

A technology of squeeze casting and mould, which is applied in the field of squeeze casting moulds. It can solve the problems that the shape of the casting does not meet the requirements of the drawing, the shape is irregular, and the shrinkage of the casting is large, so as to achieve the effect of eliminating shrinkage defects, good comprehensive performance, and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

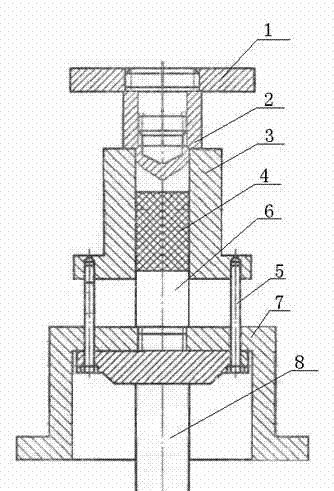

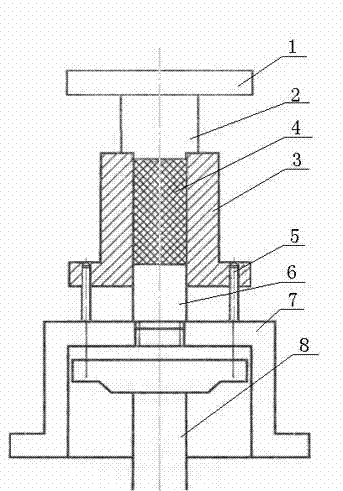

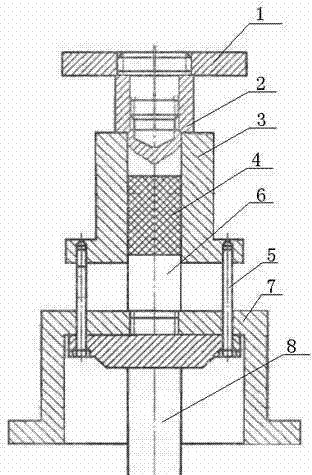

[0010] Below in conjunction with accompanying drawing, further illustrate the present invention.

[0011] Such as figure 1 figure 2 Shown, a kind of extrusion casting mold of the present invention, it comprises: upper template 1, punch 2, die 3, casting 4, bolt 5, lower pressure head 6, lower mold holder 7 and tie rod 8.

[0012] The die 2 and the lower mold base 7 are fastened by bolts 5, the pull rod 8 is penetrated on the lower mold base 7, and one end of the pull rod 8 is provided with a lower pressing head 6, and the outer side of the lower pressing head 6 is provided with The die 3 is provided with a punch 2 in the middle of the die 3 and the upper template 1 , and a casting 4 is arranged in the middle of the punch 2 and the lower pressing head 6 .

[0013] The template 1, the punch 2, the die 3, the casting 4, the lower pressing head 6, the lower die base 7 and the pull rod 8 are located on the same axis.

[0014] The lower mold base 7 and the pull rod 8 are threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com