Roll angle measurement device and method based on array-type multiple reflections

A technology of roll angle measurement and multiple reflections, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult resolution, and achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

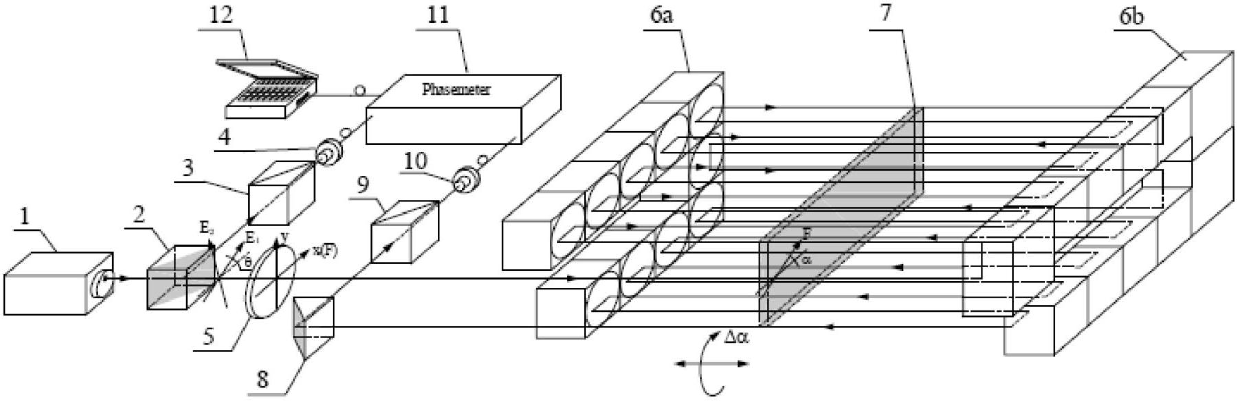

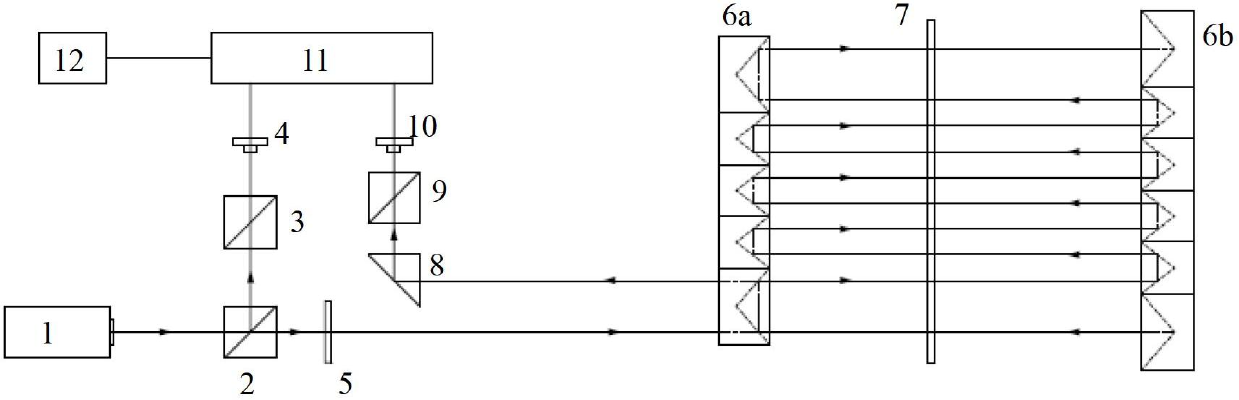

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

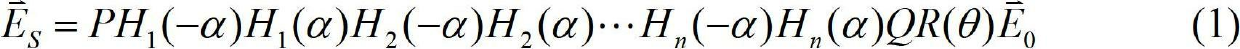

[0020] see figure 1 with figure 2 , the present invention is based on the rolling angle measuring device of array type multiple reflection, comprises dual-frequency laser 1, 1 / 2 wave plate 7 and two sets of corner cube arrays; After the optical axis of dual-frequency laser 1, beam splitting prism 2 is arranged, A first analyzer 3 and a first photoelectric receiver 4 are provided on the reflected optical axis of the beam splitting prism 2; a 1 / 4 wave plate 5 is provided on the transmitted optical axis of the beam splitting prism 2; 1 / 2 wave plate 7 is located in two sets of In the middle of the corner cube array; on the outgoing optical axis of the two sets of corner cube arrays, a right-angle reflective prism 8 is arranged, and on the reflected optical axis of the right-angle reflector 8, a second analyzer 9 and a second photoelectric receiver 10 are arranged ; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com