Detection method of self-healing breakdown of capacitor

A detection method and capacitor technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problems of short capacitor duration, inaccurate detection, and inaccurate detection of capacitor self-healing breakdown, etc., to achieve convenient use and detection Accurate, simple and reliable effect of anti-jamming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

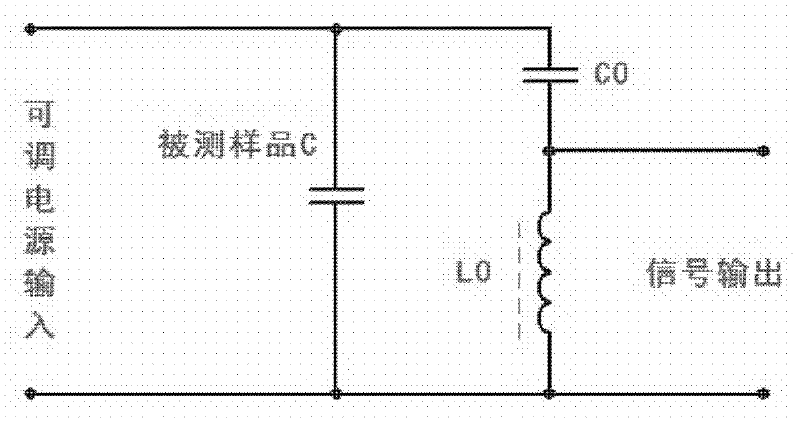

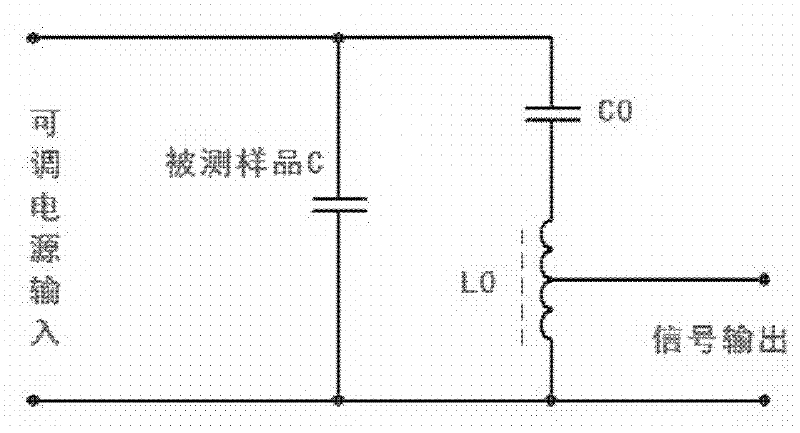

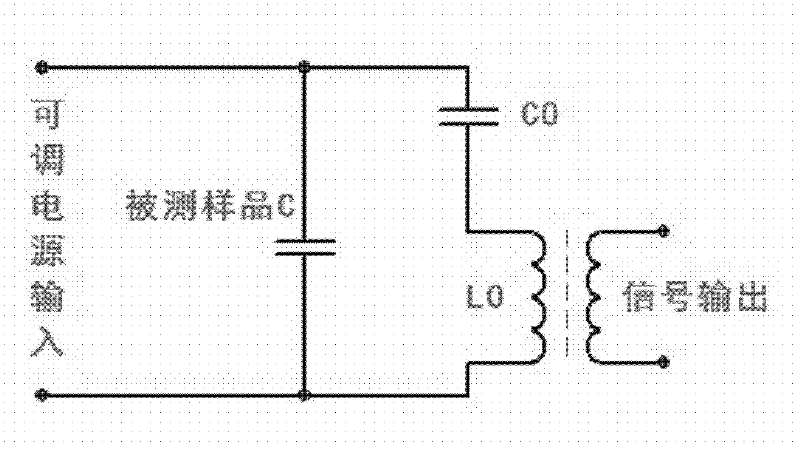

[0015] see figure 1 , in the first embodiment, the circuit used in the detection method for the self-healing breakdown of the capacitor is mainly composed of the detection capacitor C0 and the detection inductor L0, and the detection inductor L0 and the detection capacitor C0 are connected in series and parallel to the measured On the sample capacitor C, an AC adjustable power supply is connected at both ends of the circuit, and the inductance is directly output in this circuit; C0 is a small-capacity high-voltage capacitor. Since the withstand voltage of C0 is much greater than the withstand voltage of the sample capacitor C under test, ensure that C0 There will be no breakdown or self-healing breakdown; the capacitance selected by C0 is much smaller than the capacitance of the sample capacitor C under test, and the instantaneous large energy of the sample capacitor C under test is generated by the power supply and the sample under test when self-healing breakdown occurs. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com