Sodium niobate nanowire photocatalyst and preparation method thereof

A technology of photocatalyst and sodium niobate, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve limited problems and achieve simple process and short process , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

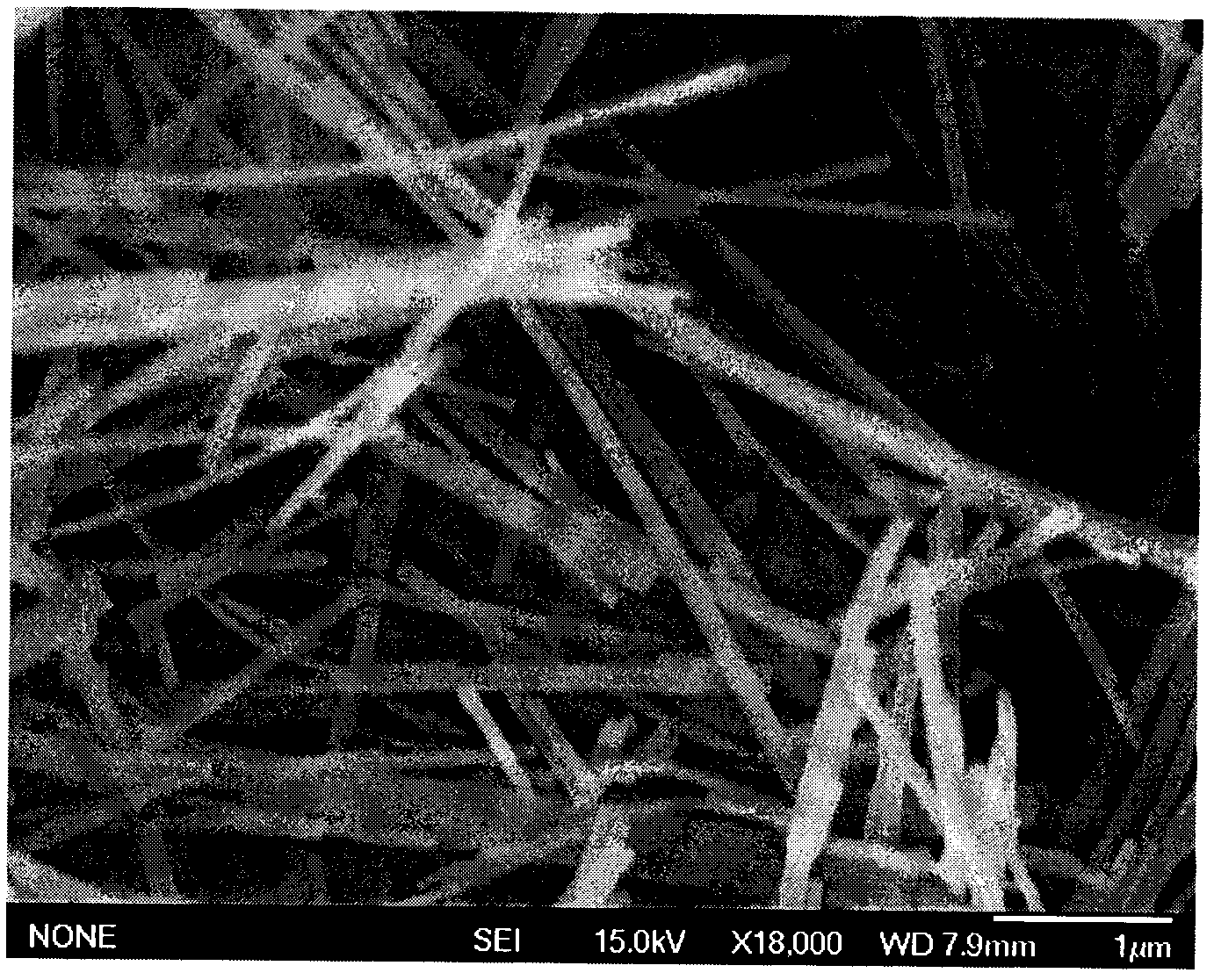

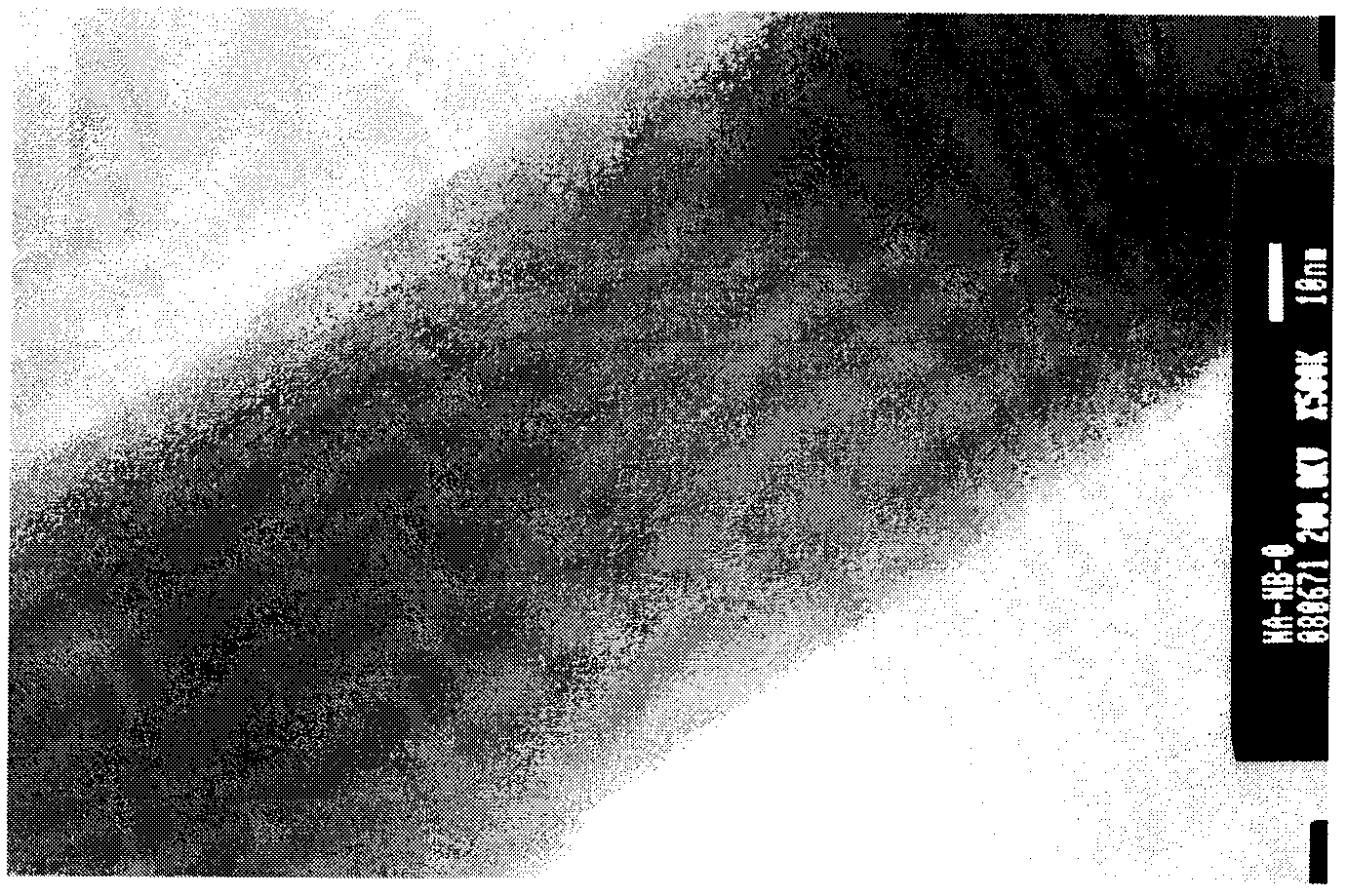

Image

Examples

example 1

[0019] Granular NaNbO was synthesized by solid phase method 3 , the Nb 2 o 5 and Na 2 CO 3 The solid powder is mixed according to the stoichiometric ratio of the reaction, the solid powder is added with absolute ethanol and ground in an agate mortar, calcined at 800°C for 4h, taken out and reground, and then calcined at 900°C for 5h. In a typical example, NaNbO is added to a methanolic solution 3 The powder and chloroplatinic acid were irradiated by a 400W high-pressure mercury lamp for 1 hour, and the obtained precipitate was filtered, washed with distilled water and ethanol, and dried in an oven at 70° C. for 12 hours. Place the solid-phase synthesized photocatalytic material sample on the sample stage in the reactor and spread it flat, and then inject CO into the reaction system after vacuuming the system. 2 (about 1 atm), then use a syringe to add water (0.4ml), keep the reactor away from light for 10h, use the gas circulation pump to make the photocatalytic reaction ...

example 2

[0021] In a typical example, 1 g of P123 was added to 25 ml of distilled water, and 5 g of Nb(OC 2 h 5 ) 5 . 10 ml of a 0.8 g / ml sodium hydroxide solution was added dropwise. After stirring for one hour, the resulting solution was transferred to an autoclave and heat-treated at 200 °C for 24 hours. The resulting precipitate was filtered, washed with distilled water and ethanol, and dried overnight in an oven at 70°C. The obtained powders were calcined at 550° C. for 4 hours, and returned to room temperature by natural cooling. In a typical example, NaNbO is added to a methanolic solution 3 The powder and chloroplatinic acid were irradiated by a 400W high-pressure mercury lamp for 1 hour, and the obtained precipitate was filtered, washed with distilled water and ethanol, and dried in an oven at 70° C. for 12 hours. NaNbO was added to the methanolic solution 3 The powder and chloroplatinic acid were irradiated by a 400W high-pressure mercury lamp for 1 hour, and the obtai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap