Roller support and hot platen combined segmented continuous flat hot press

A technology of roller support and hot-pressing plate, which is applied in the direction of flat products, household components, household appliances, etc., can solve the problems of no hot-pressing plate and roller segmented hot-pressing production line, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

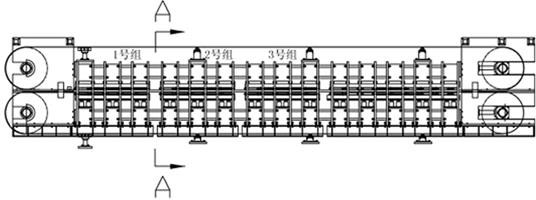

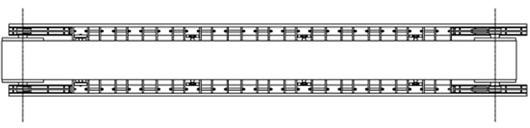

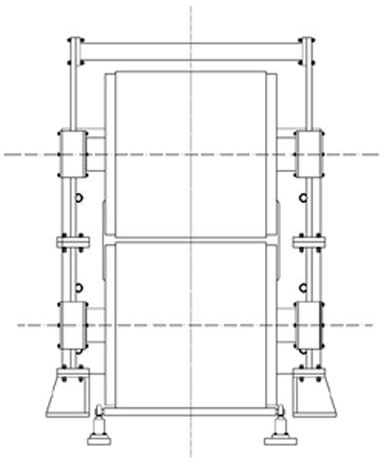

[0028] Please refer to the attached drawings. The present invention includes two upper and lower driving rollers 10, 11, upper and lower two driven rollers 1, 19 and two steel belts 4, 18 on the surrounding moving rollers, which are arranged on the frame 5. The upper and lower hot pressing plate assemblies 7, 15 are connected in series. In the middle of the upper and lower hot pressing plate assemblies 7, 15 are upper and lower steel belts 4, 18 driven by moving rollers, forming a segmented type Continuous flat pressing hot press, each set of upper and lower hot pressing plate components 7, 15 is composed of upper and lower combined hot pressing plate 31 components, the outer layer of the upper and lower hot pressing plate components 7, 15 is upper and lower hot pressing Board 6, 16.

[0029] The multiple sets of upper and lower hot press plate assemblies 7, 15, each group consists of several parallel steel plates 22, which are fixed by a connecting shaft 29 to form a hot press f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com