Quantitative taking-out can

A tank body and discharge port technology, which is applied in the field of quantitatively taking tanks, can solve the problems of many human factors, many procedures, complex structure, etc., and achieve the effects of one-hand operation, reduced procedures, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

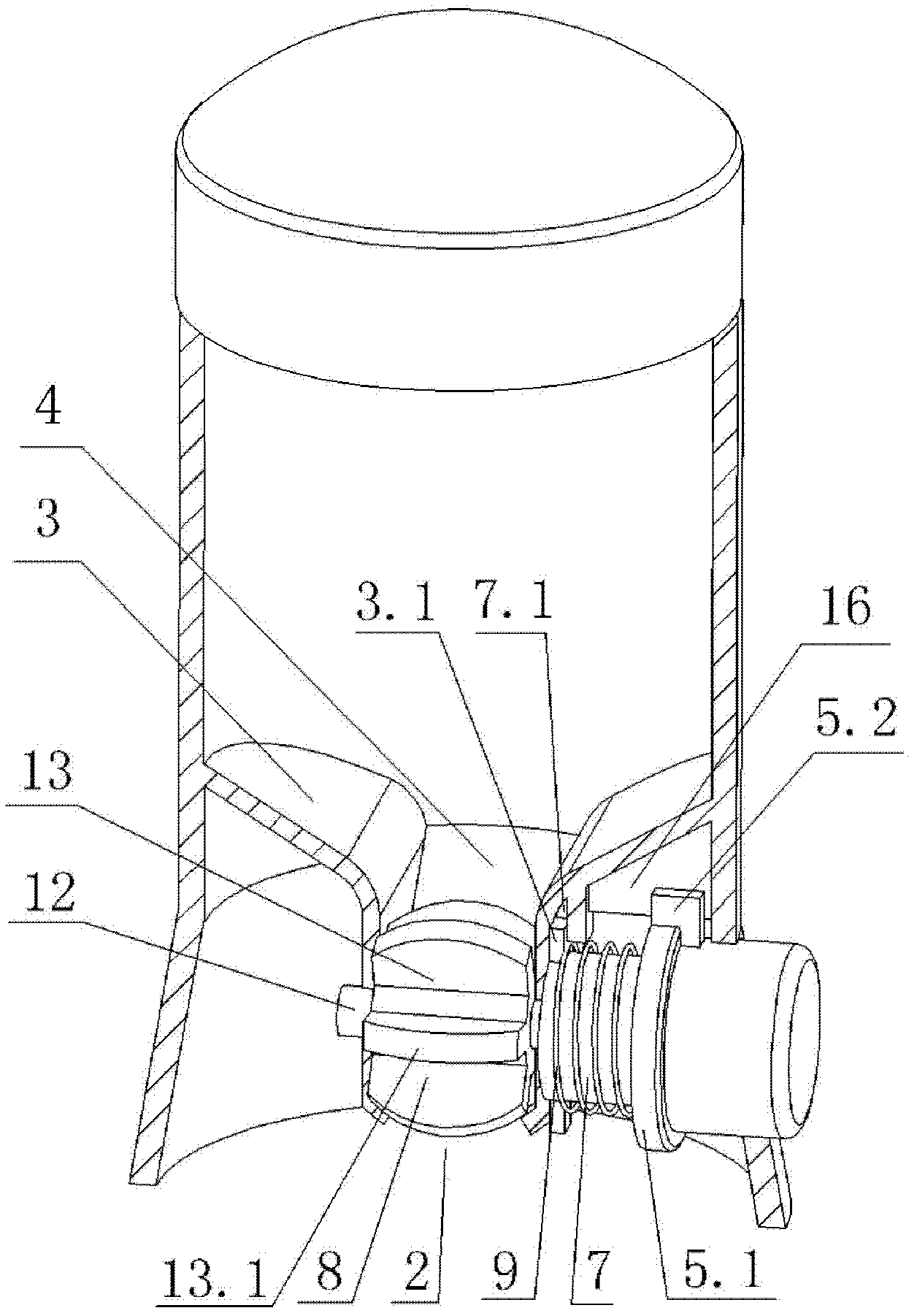

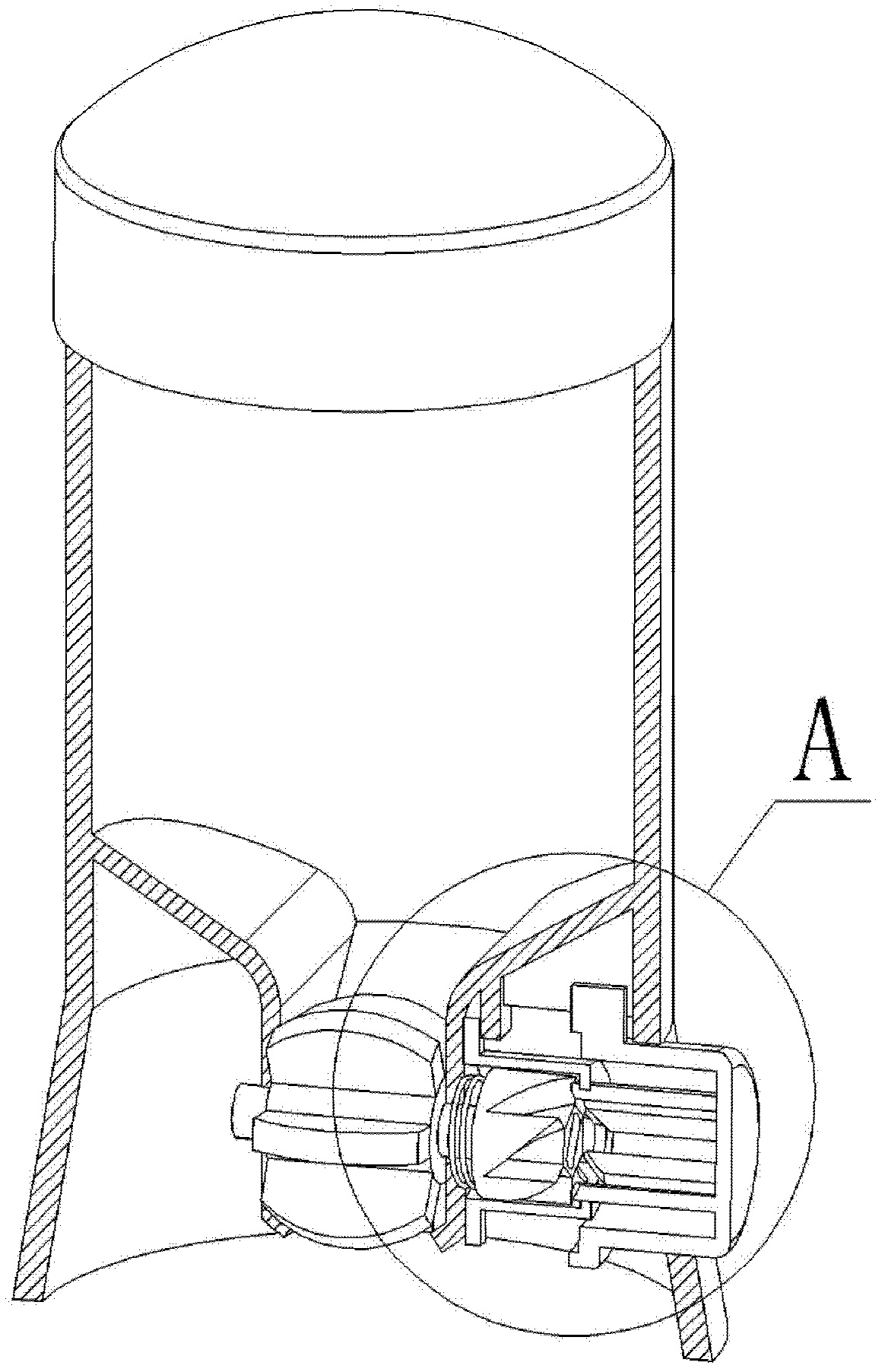

[0031] like Figure 1 to Figure 10 As shown, the quantitative taking tank of the present invention includes a tank body 1 for filling materials with fluidity, such as powder particles such as filling salt. It is relatively stable when placed, and the lower part of the tank body 1 is formed with a tapered wall whose diameter gradually increases. The tank body 1 is also formed with a discharge port 2 , and in this embodiment, the discharge port 2 is formed at the lower part of the tank body 1 . The tank body 1 at the discharge port 2 is equipped with a quantitative discharge device for quantitatively discharging fluid materials in the tank body 1 . The quantitative discharge device includes a pressing mechanism that forms a linear motion through pressing, an intermediate conversion mechanism that converts the linear motion formed by the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com