Airlift circulating membrane-bioreactor with independent cleaning of membrane module unit

A bioreactor and bioreaction tank technology, applied in sustainable biological treatment, biological water/sewage treatment, membrane technology, etc., can solve the problems of difficult independent maintenance and online cleaning of membrane units, so as to facilitate manual operation, repair and maintenance Convenience and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

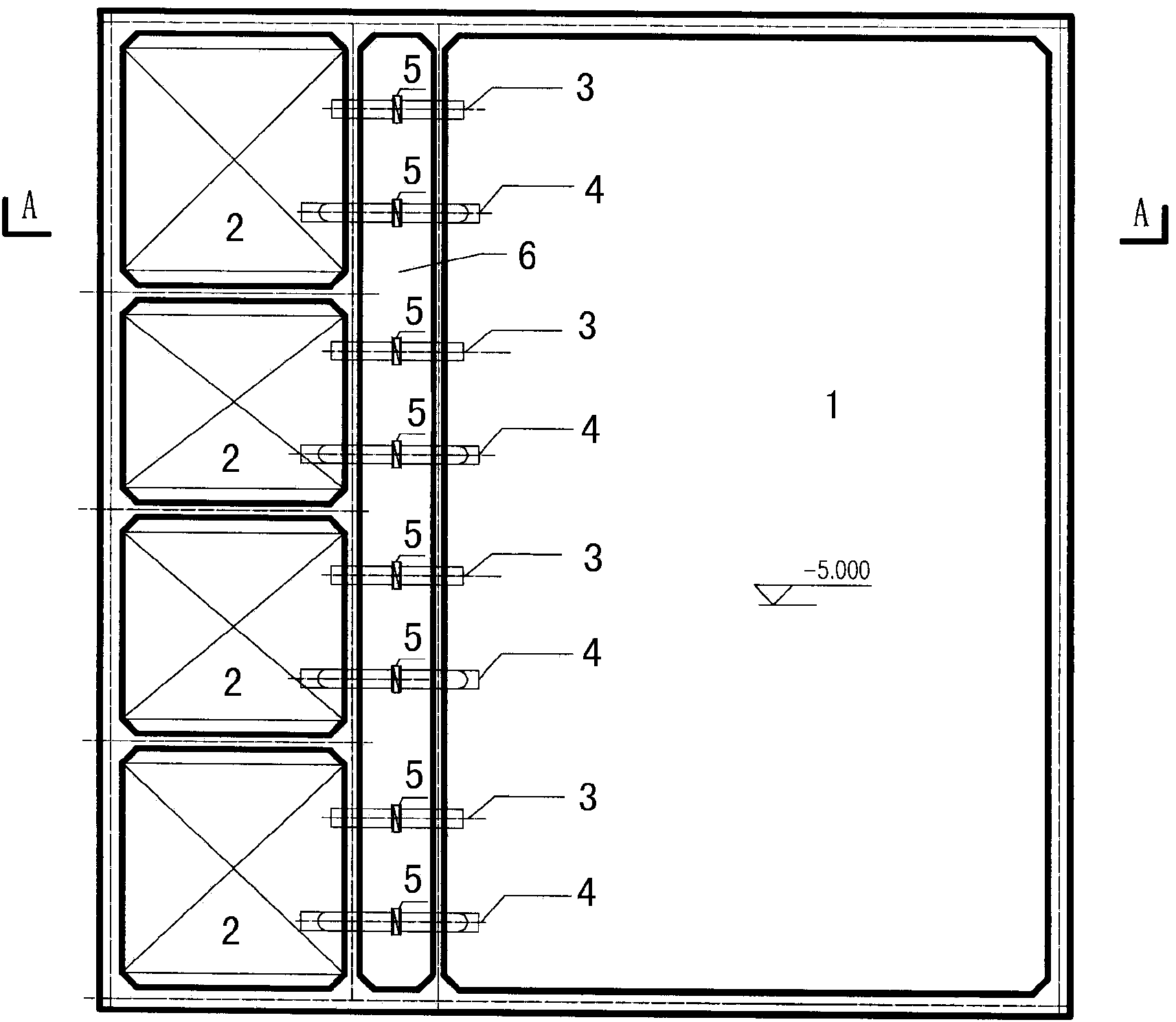

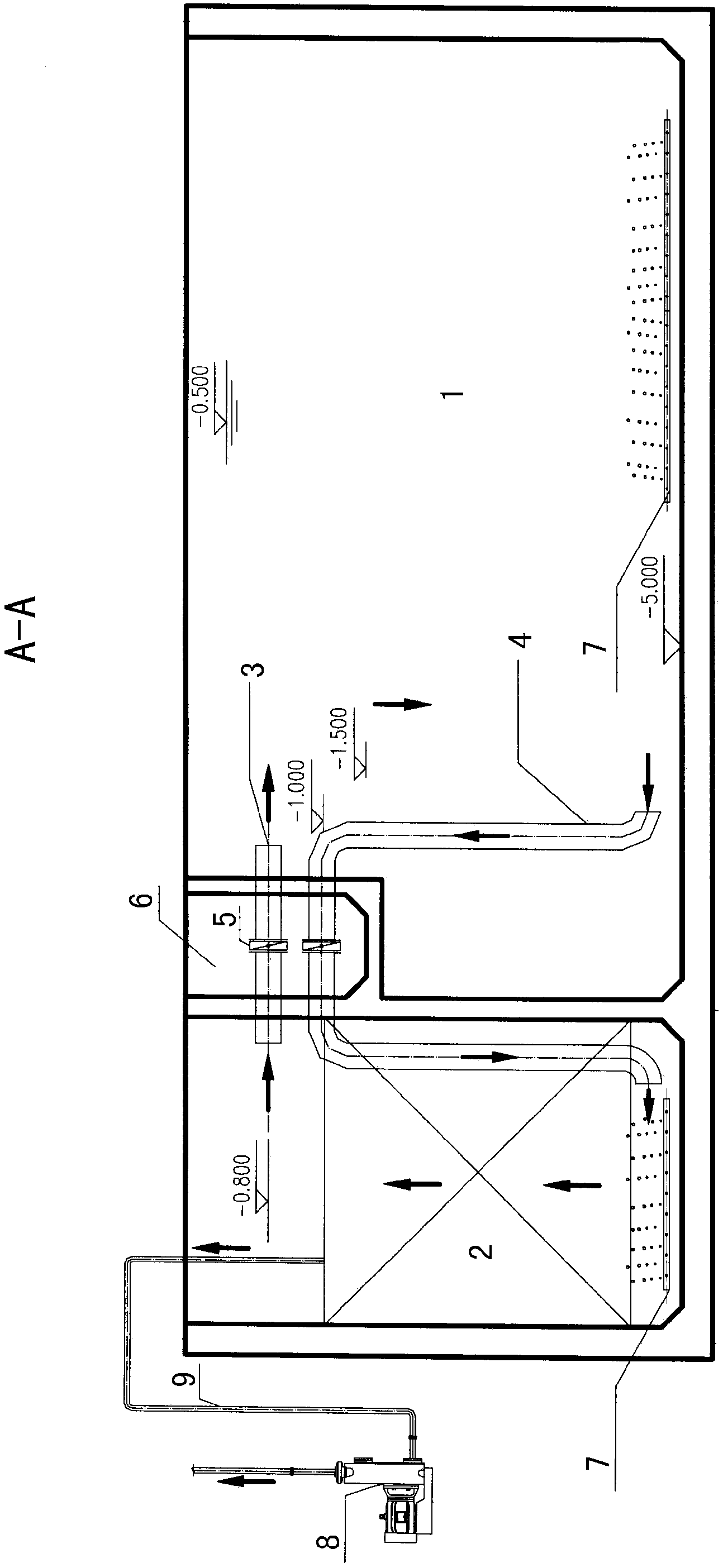

[0028] The membrane module unit provided by the present invention can be cleaned independently and the air-lift circulation membrane-bioreactor is mainly composed of:

[0029] Biological reaction unit, membrane module unit, U-shaped airlift circulation pipe and exchange pipe and the stop valve and valve operation corridor installed on it; the biological reaction unit is composed of a single biological reaction tank, and the membrane module unit is composed of It is composed of at least two independent membrane filter tanks equipped with membrane modules; the biological reaction tank and the membrane filter tank are separated by a partition wall; a U-shaped air-lift circulation pipe equipped with a stop valve is used between each membrane filter tank and the biological reaction tank It communicates with the exchange pipe; the cut-off valve refers to a valve with the function of regulating flow and closing the fluid channel, including cut-off valves, ball valves and butterfly val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com