Multifunctional combined magnetization equipment in magnetized fertilizer production

A multi-functional and compound technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of not meeting the requirements of use, poor quality of magnetized fertilizers, and poor magnetization effect, so as to improve the quality of magnetized fertilizers and their nutrient absorption. rate and special magnetization equipment to shape, absorb thoroughly, and the effect of good magnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

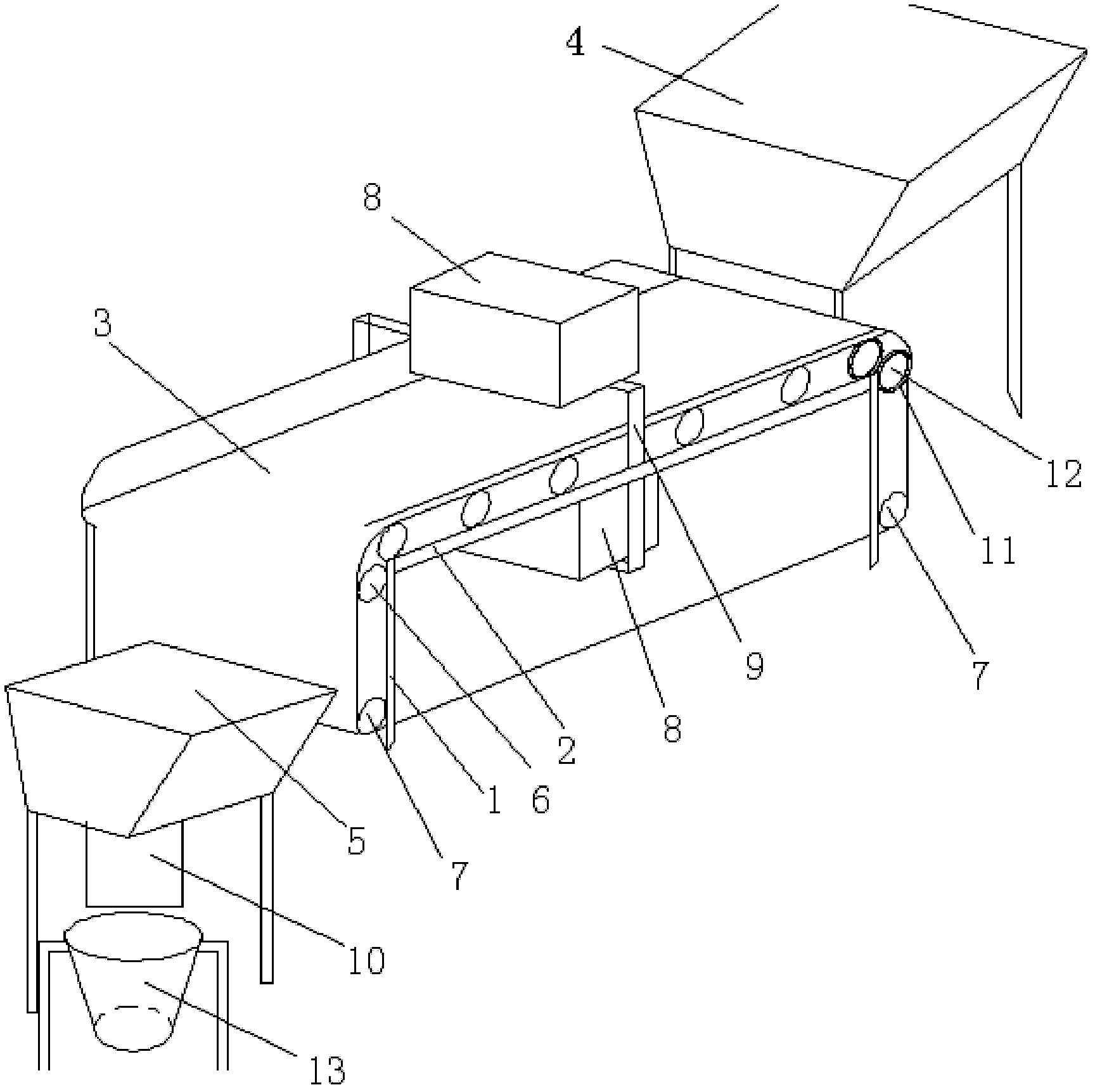

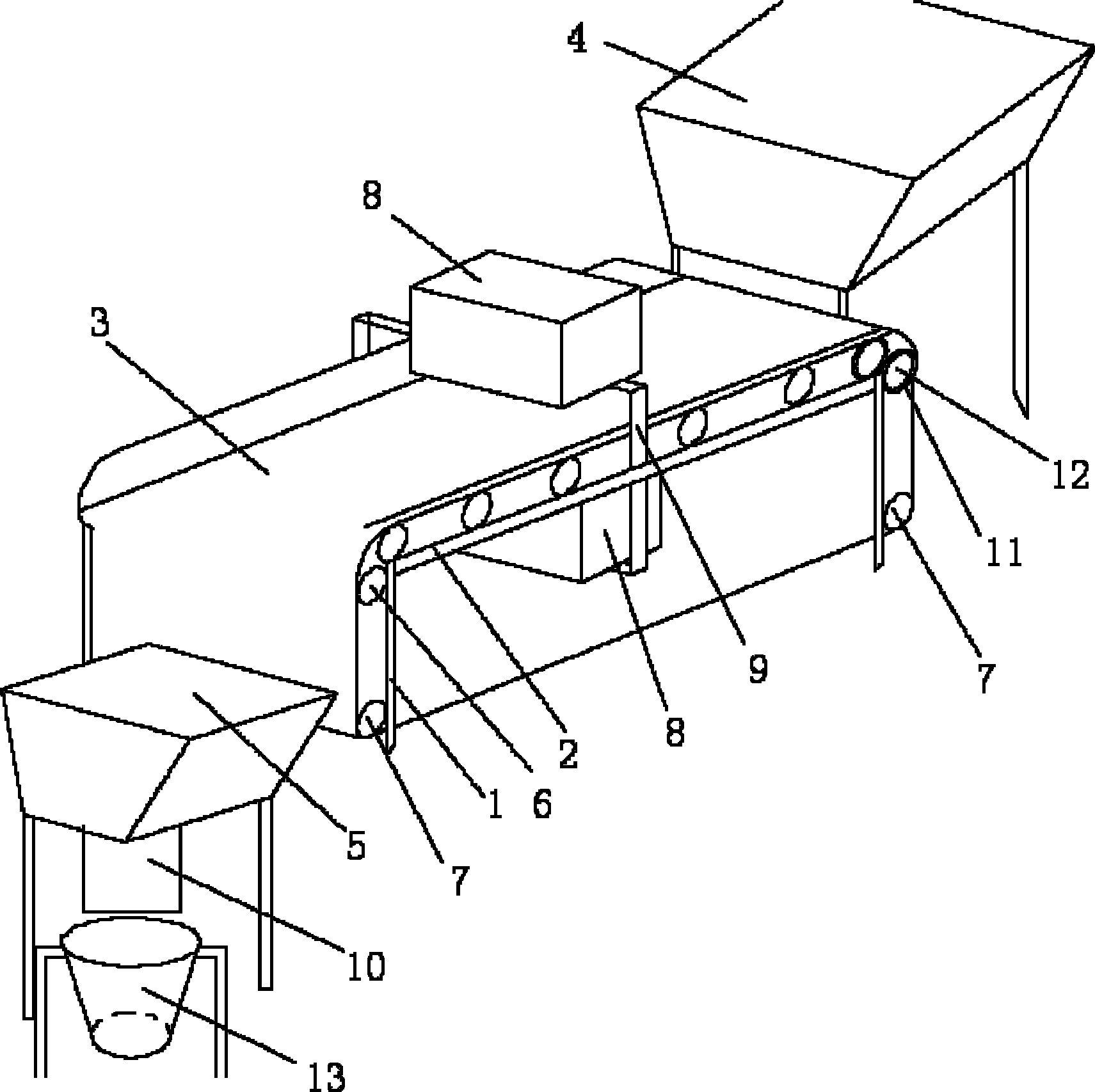

[0019] Referring to the accompanying drawings, a multifunctional composite magnetizing equipment in the production of magnetized fertilizers includes a bracket 1 on which a crossbeam 2 is erected, a circulating conveyor belt 3 is arranged between the beams 2, and the feeding end of the circulating conveyor belt 3 A feed hopper 4 is erected above, and a discharge hopper 5 is erected below the discharge end of the endless conveyor belt 3. 1. Magnetized boxes 8 are erected on the top and bottom of the circular conveyor belt 3 between the conveyor rollers on the discharge end, and the magnetized boxes 8 are respectively fixed and installed on the beam 2 through the fixing frame 9. There are guides in the magnetized box 8. Magnetic material; the upper conveying rollers at the discharge end are hollow cylinders 11 and 12, and the cylinders 11 and 12 are provided with cylindrical magnetized rollers filled with NdFeB magnet powder; a funnel is provided below the discharge port of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com