Sleeve-type photo-bioreactor

A photobioreactor and sleeve-type technology, which is applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of untimely replenishment and gas-liquid mixing effect Poor, low light efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

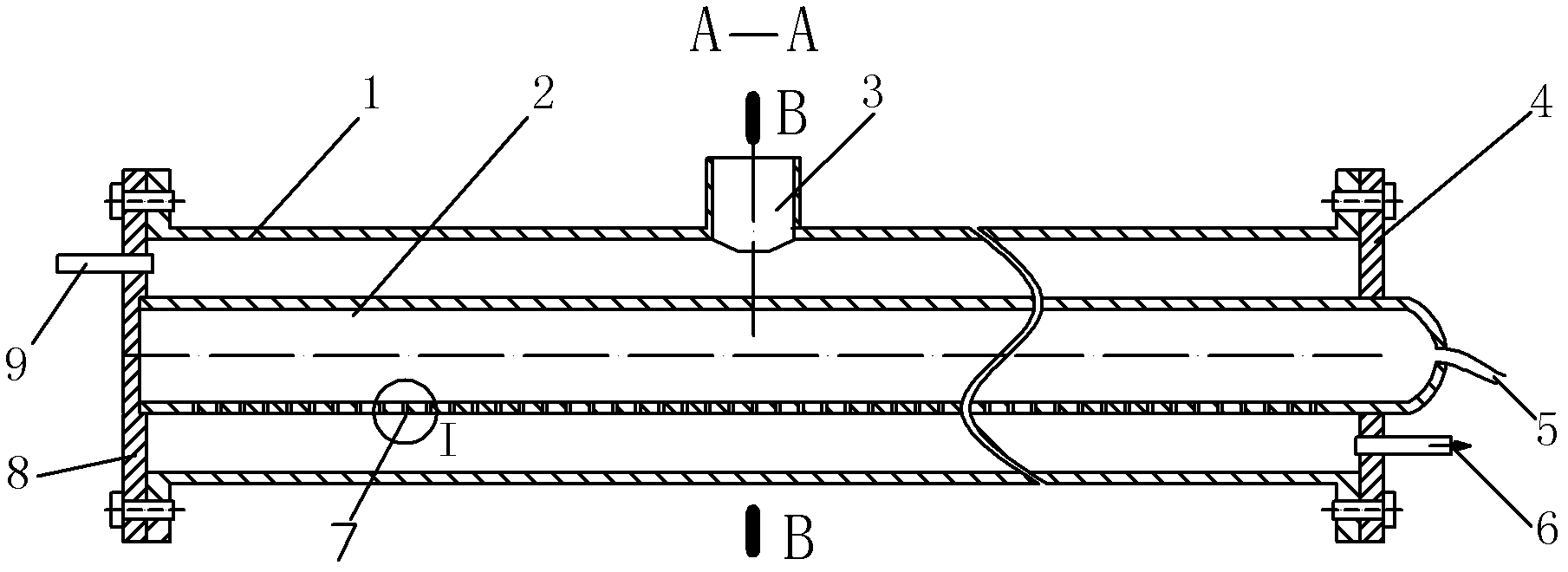

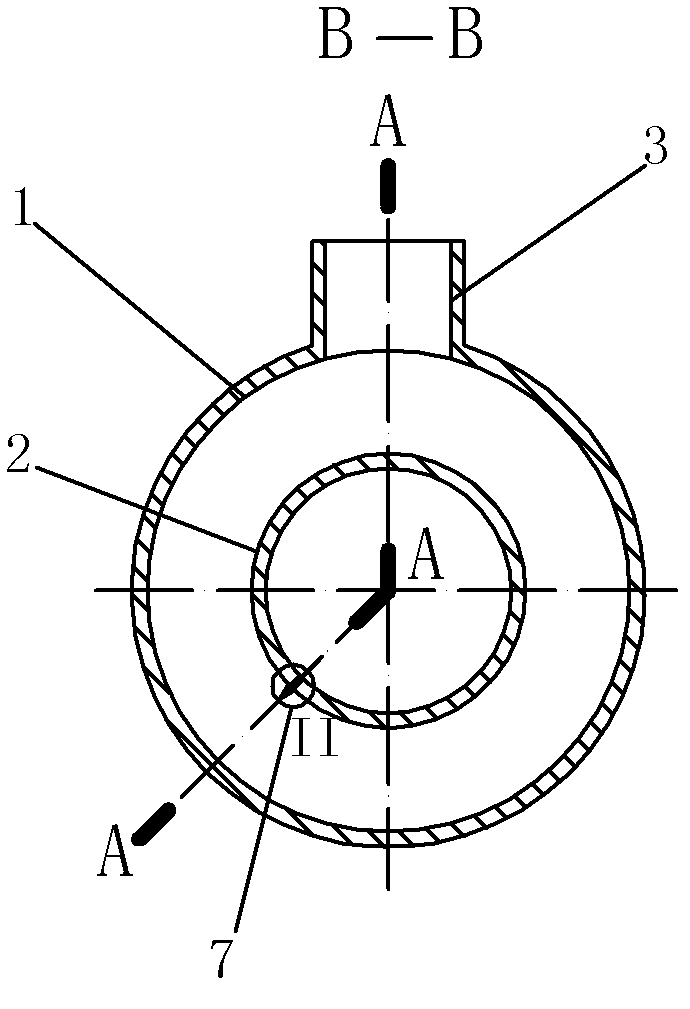

[0033] Embodiment: process out a set of length and be that the casing type photobioreactor that 1m small-scale experiment is used, as Picture 1-1 shown.

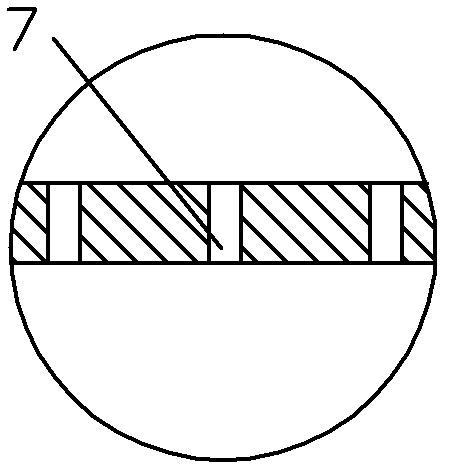

[0034] Wherein: the inner diameter of the transparent outer pipe 1 is 200mm, and the material is selected from glass; the outer diameter of the transparent aeration pipe 2 is 100mm, and its material is selected from transparent plastic; one end of the transparent aeration pipe 2 is connected with an air inlet pipe 5, such as Figure 1-2 with Figure 1-2 As shown, a row of radial aeration holes 7 is opened on the transparent aeration pipe 2 at 45° below the backlight area obliquely along the axial direction of the transparent aeration pipe 2. The diameter of the aeration holes 7 is 1mm, and the opening density is A hole is opened every 20mm; an exhaust port with a diameter of 30mm is opened directly above the transparent outer pipe 1 and an exhaust pipe 3 is connected to it; The ends are sealed and connected with flanges 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap