Steel tube locked anchor rod construction method

An anchor bolt construction and steel pipe technology, which is applied in basic structure engineering, construction, sheet pile wall and other directions, can solve the problems of complex process, high cost, unformed sand and soil, etc., and achieves simple process, small working surface and simple equipment. Effect

Inactive Publication Date: 2012-09-12

GANSU JIANGONG ENG CONTRACTING

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the Luoyang shovel artificial hole forming method is that the efficiency is extremely low, the sandy soil is not formed, and the hole cannot be formed at all; the mechanical drilling casing follow-up hole forming method is that the ends of the drill pipe and the casing are equipped with alloy steel drill bits. With the drilling function of rotary and percussion, the casing and the drill pipe are drilled at the same time, so that the casing follows the retaining wall without using the mud retaining wall; high-pressure water is pumped from the drill pipe, from the cavity between the drill pipe and the casing Flow out, take out the drilling cuttings and soil to form anchor holes, suitable for the construction of prestressed anchor cables or prestressed anchor bolts on the foundation pit wall with a hole diameter of 150 mm

This hole-forming method has complicated process, high requirements on the working surface, long construction period, high noise and high cost. The cost of drilling a 1m hole is between 280 and 300 yuan

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

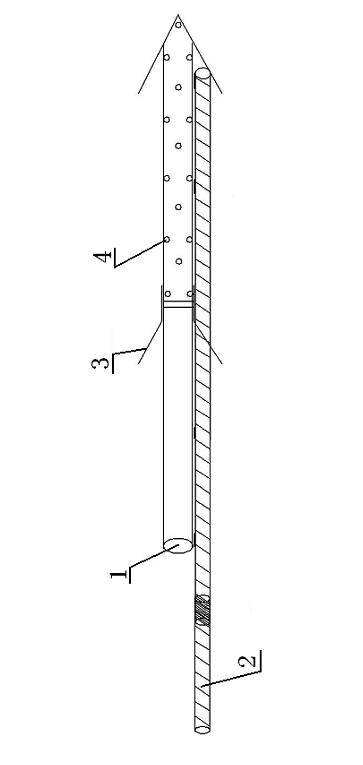

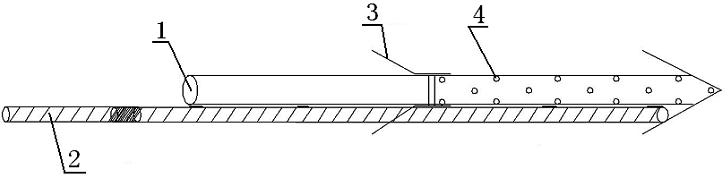

The invention relates to a steel tube locked anchor rod construction method. The method comprises the following steps of: (1) deploying points by using a conventional method; (2) putting an anchor shank in place; (3) driving a guide steel tube in a steel tube locked prestressing anchor rod and a deformed steel bar anchor rod into soil at the deployed points to designed length by using the anchor shank; (4) mixing cement slurry; (5) injecting the cement slurry into the guide steel tube by an injection pump under the pressure of 0.5-3MPa, and stopping injecting the slurry when cement slurry flows out of a hole formed in the soil by the guide steel tube locked pretressing anchor rod; and (6) after the soil is solidified for seven days and the strength is above 75%, carrying out pull-push detection on the guide steel tube locked pretressing anchor rod, wherein the detection quantity is no less than 3% and the pull-push force is greater than a preset value. The method provided by the invention is simple in process and low in construction cost, and solves the problems admitted in the building industry that anchor rods and soil nails difficultly form holes in a soft ground, saturated soil, sand soil and silty clay in deep foundation pit support.

Description

technical field [0001] The invention relates to the technical field of prestressed anchor rod construction, in particular to a steel pipe locking anchor rod construction method. Background technique [0002] With the development of the national economy, there are more and more high-rise buildings and more and more deep foundation pits. According to national regulations, all deep foundation pits must be supported. The conventional forms of foundation pit support include: support piles, soil nail walls and other forms. The horizontal thrust of the foundation pit on the soil-nailed wall and retaining pile must be resisted by the horizontal tension of the prestressed anchor. It can be integrated with the soil as a whole, so as to be economically reasonable. However, there are the following difficulties in the construction of prestressed anchor bolts: (1) It is a difficult problem to form holes on soft ground, saturated soil, sandy soil, and silty clay, and this is the key t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D5/74

Inventor 黎粤桥王红何霁耀

Owner GANSU JIANGONG ENG CONTRACTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com