Apparatus for underpinning reinforced concrete column by adopting prestress technology

A technology of reinforced concrete columns and prestressed steel bars, which is applied in building maintenance, construction, building construction, etc., can solve the problems that the screw cannot be taken out and the cost is high, and achieves the effects of low cost, convenient construction and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

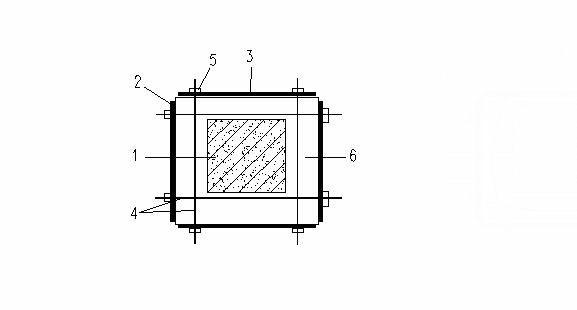

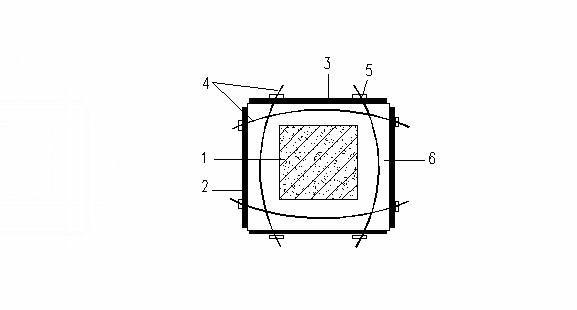

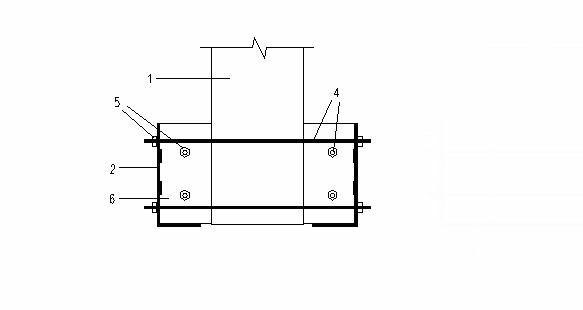

[0017] As shown in the figure, a device for underpinning reinforced concrete columns using prestressing technology improves the underpinning bearing capacity by increasing the interface pressure between old and new concrete, and builds reinforced concrete wrapped column beams 6 around the reinforced concrete columns 1 to be underpinned , around the outside of the reinforced concrete beam 6 are respectively provided with a direction-1 restraint steel plate 2 and a direction-2 restraint steel plate 3 for enclosure, and prestressed tendons 4 pass through the reserved direction-1 restraint steel plate 2 and direction-2 restraint steel plate 3 Prestressing is applied to the reserved round hole by tensioning the prestressed steel bars 4, and the two ends of the prestressed steel bars 4 are fixed by anchors 5. The present invention is improved on the basis of the underpinning of the original column-wrapped beam, and adopts prestressing technology to increase the vertical pressure on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com