High-temperature resistant floating sealing device for cone bit

A technology of roller cone bit and floating seal, which is used in construction and other directions to avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

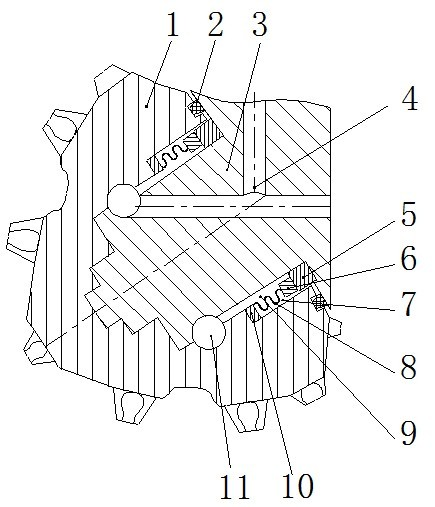

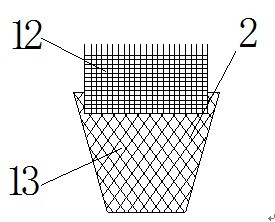

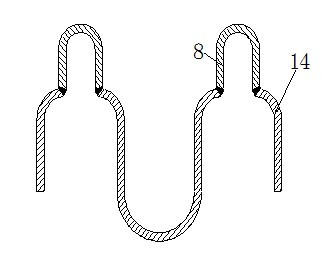

[0016] Such as figure 1 , figure 2 , image 3 As shown, a high temperature resistant roller cone bit floating sealing device of the present invention is mainly composed of a dynamic sealing ring 6, a static sealing ring 5, a welded bellows 8, a dynamic ring seat 10 and a sand control seal 2. The dynamic sealing ring 6 , the static sealing ring 5, the welded bellows 8 and the moving ring seat 10 are installed in the inner hole of the cone 1 and the sealing cavity formed by the tooth palm 3; 1 rotate together, the cone 1 rotates around the center of the tooth palm 3, and the rotary dynamic seal is formed by the dynamic seal ring 6 on the cone 1 and the static seal ring 5 on the tooth palm 3; through the dynamic seal ring 6 and the static seal ring 5 to isolate the drilling fluid in the outer side 7 of the welded bellows and the lubricating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com