Compact type fuel gas stove

A gas cooker, a compact technology, applied in household stoves, heating fuel, household appliances, etc., can solve problems such as limited effect, component failure, poor heat insulation effect, etc., and achieve the effect of obvious and beautiful layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

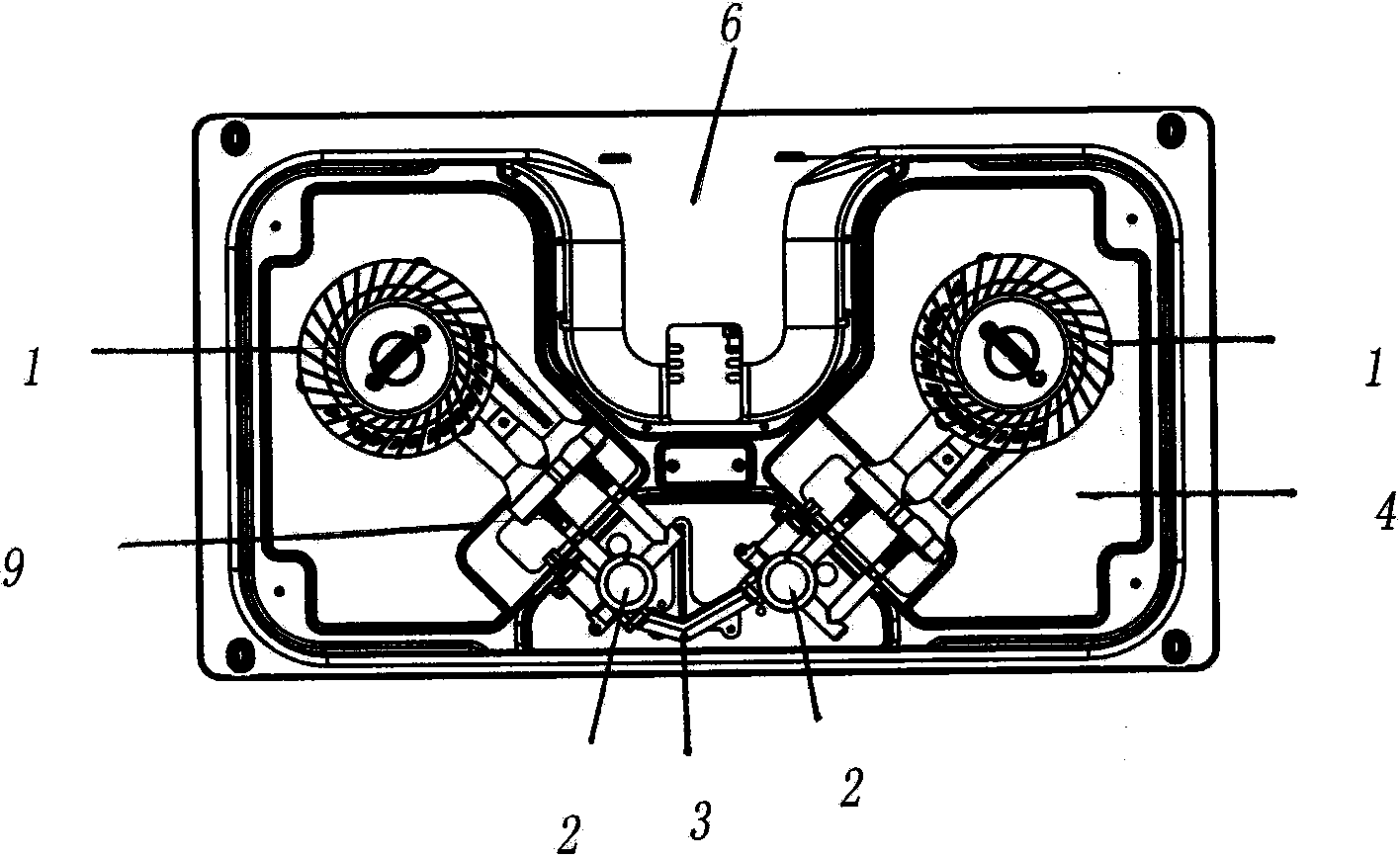

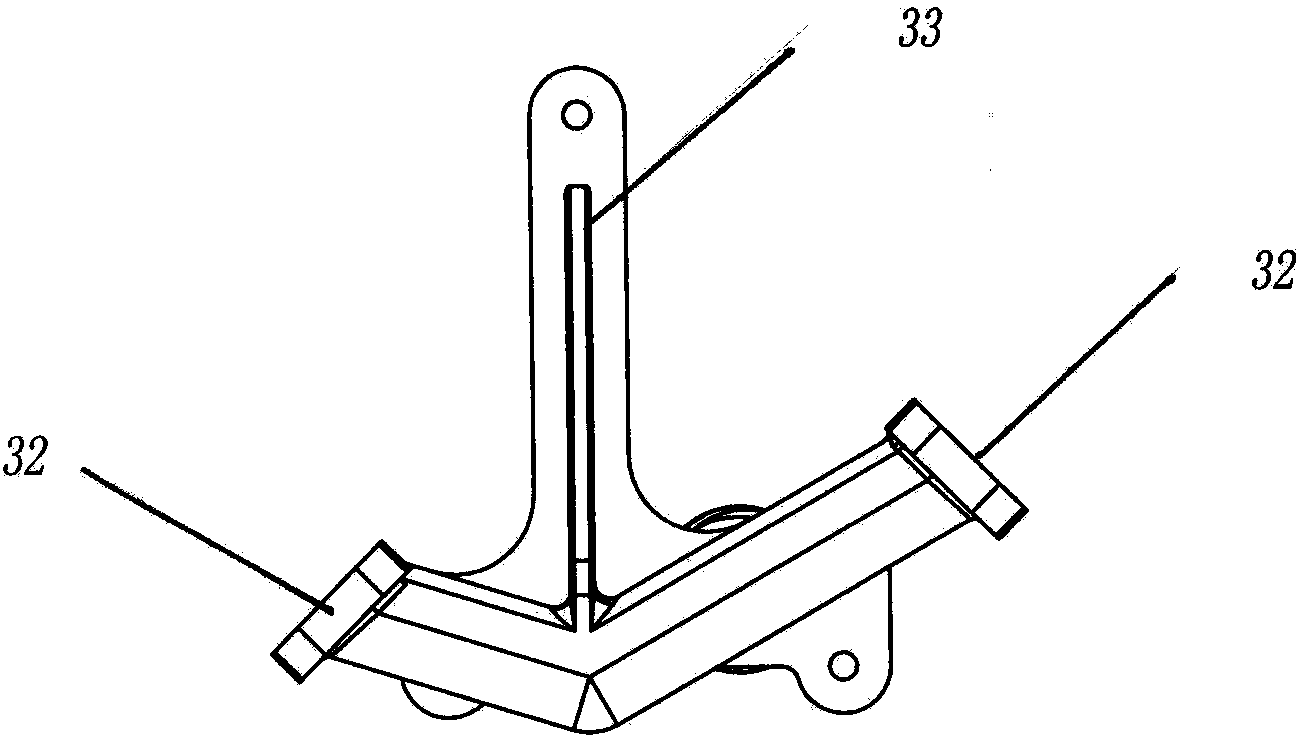

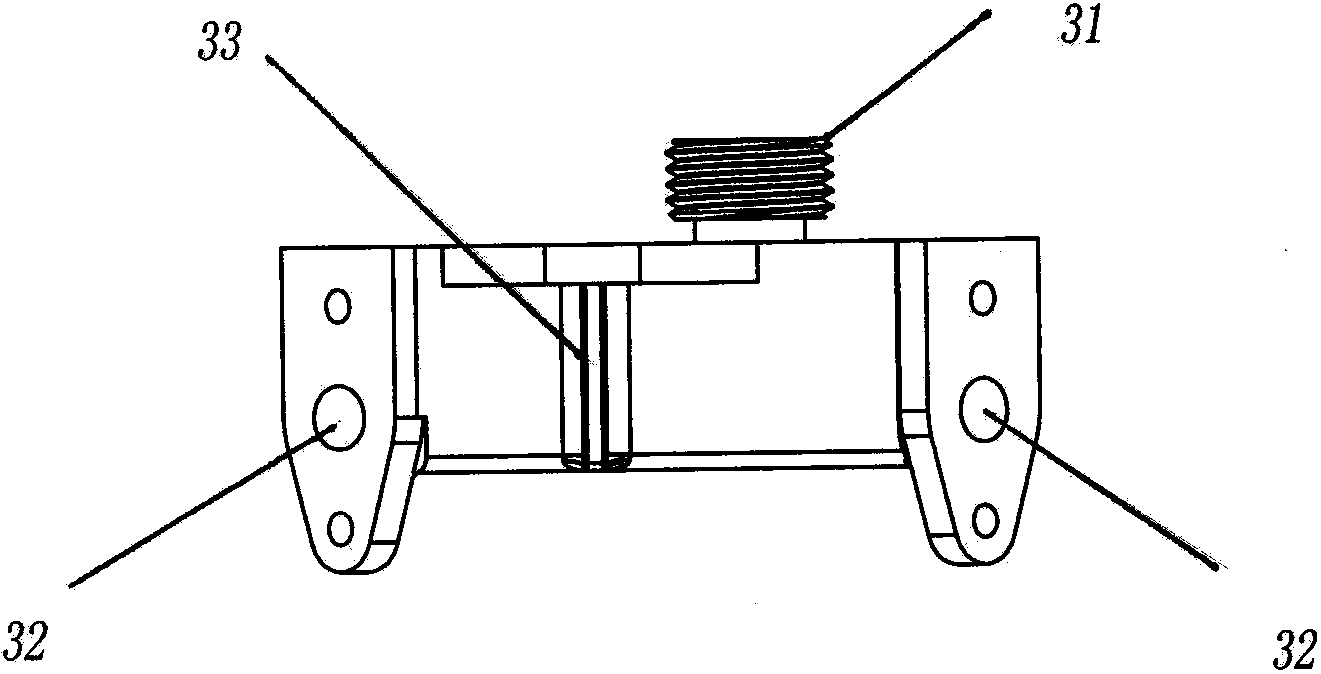

[0037] In this embodiment, a double-burner cooker with two burners most used in household cookers is taken as an example for illustration. figure 1 It is a schematic diagram of the front of a compact gas cooker of the present invention without a panel. The compact gas cooker includes a panel (not shown in the figure), a burner 1, a gas valve 2, a gas valve connecting bracket 3, a cooker base 4, an electronic Components 5, burner 1, gas valve 2, gas valve connecting bracket 3, electronic components 5 are installed on the cooker base 4, the nozzle 9 on the gas valve 2 is inserted into the injection pipe of the burner 1, and the gas valve connecting bracket 3 The air inlet passes through the cooker base 4 and can be directly connected to the air intake pipe. Electronic components such as the battery box and pulse controller are hidden in the heat insulation area 6, and tempering cannot affect the components in the heat insulation area 6. The heat insulation The zone 6 can be stam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com