Heat pump dehumidifying band-type drying machine

A technology of heat pump dehumidification and wet belt type, which is applied in the direction of progressive dryers, dryers, and drying solid materials, etc., can solve the problems of low energy utilization rate, high maintenance work, and large environmental pollution, and achieve obvious energy saving effects. Low maintenance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

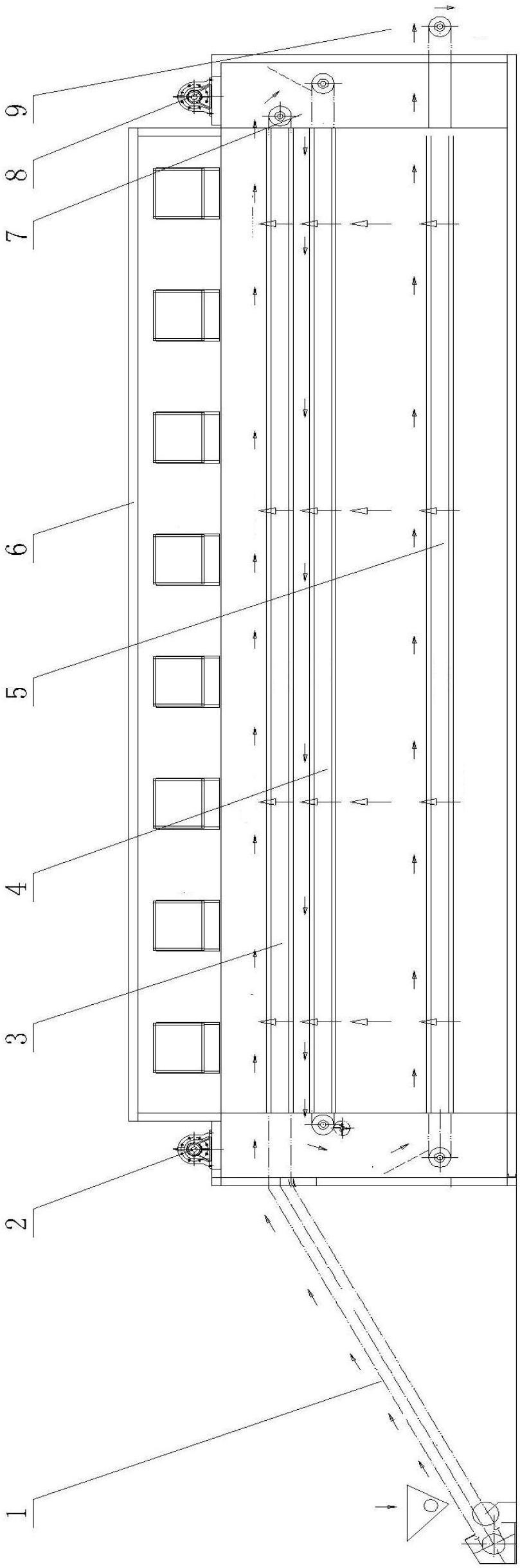

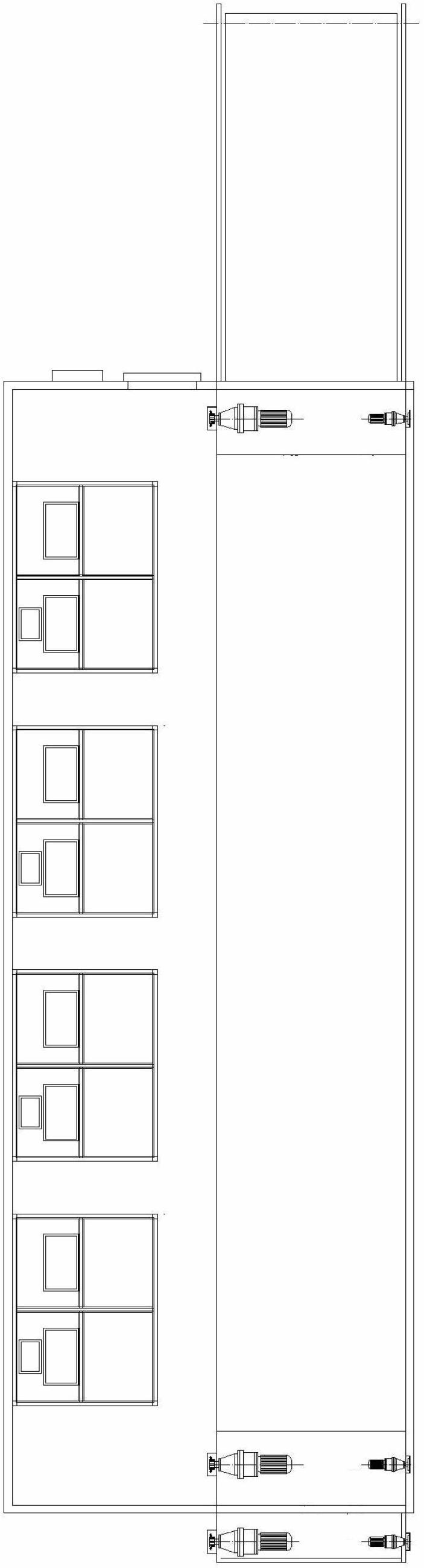

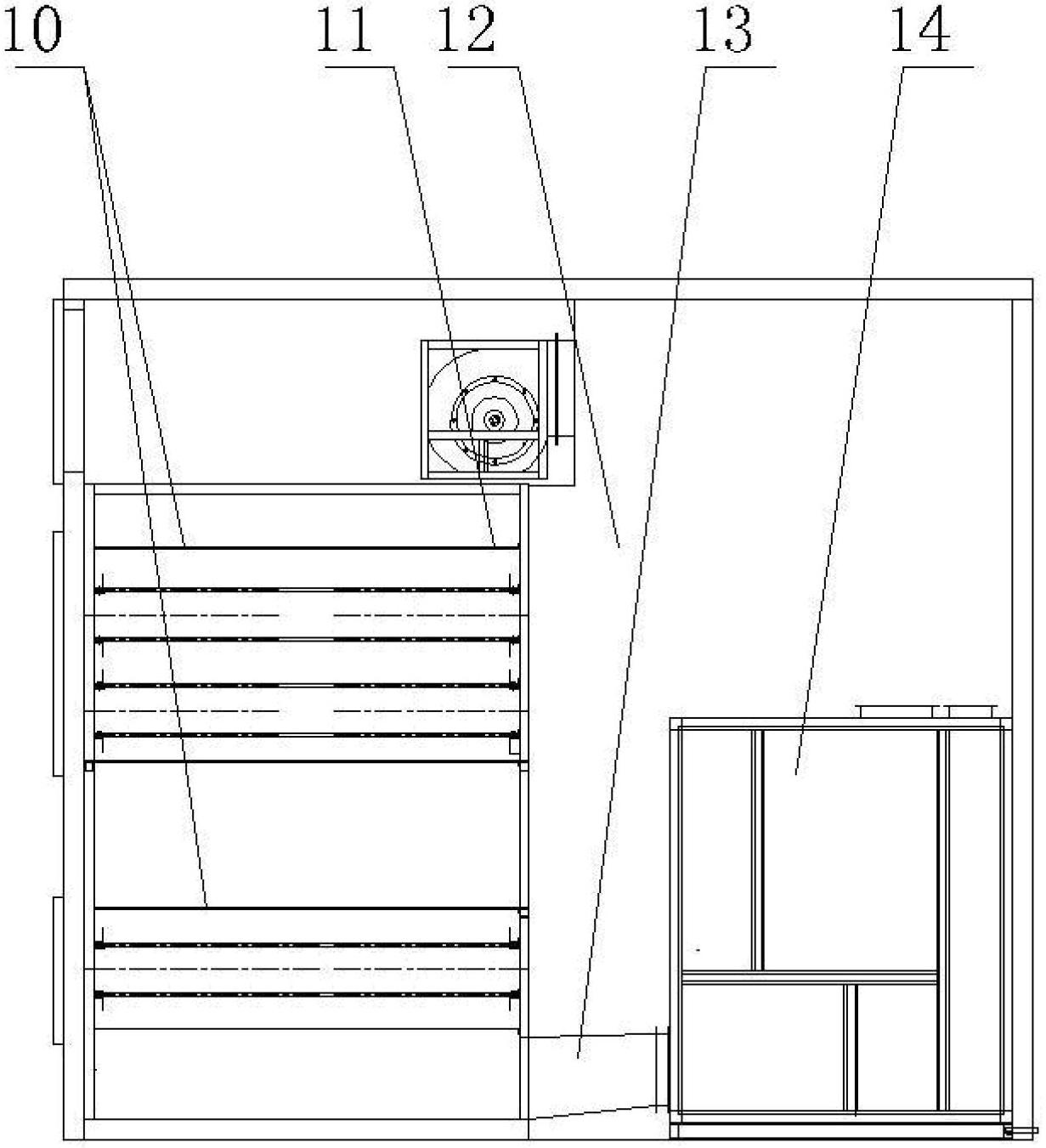

[0030] Heat pump dehumidification belt dryer, such as Figure 1-3 As shown, it includes a feeding device 1, at least one layer of mesh belt and a heat pump dehumidification drying device 14, the mesh belt is arranged in the insulation box, and the feeding device 1 is arranged on the outside of the insulation box and is positioned at one end of the mesh belt, It is used to transport the materials to be dried to the mesh belt. The insulation box at the end of the mesh belt is provided with a material outlet. The heat pump dehumidification and drying device 14 is installed in the auxiliary box. The heat pump dehumidification and drying device 14 The air supply pipe 13 is connected to the bottom of the heat preservation box. The air supply pipe 13 is made of stainless steel or aluminum plate, and the wind speed of the air pipe is less than 15m / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com