Acoustic emission sensor fixing device for concrete surface

An acoustic emission sensor, concrete surface technology, applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., to achieve good practical significance and economic effects, easy operation, stable and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

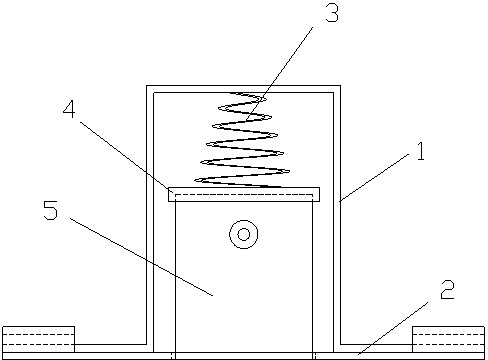

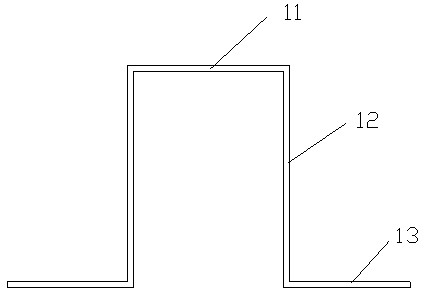

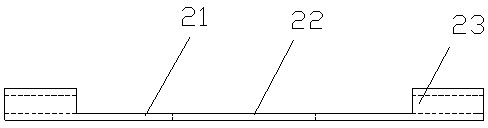

[0017] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 , figure 2 As shown, the acoustic emission sensor fixing bracket 1 of the fixing device of the present invention is a steel plate bending member, including an upper top plate 11, two pins 13 below, and two connecting pins 11 and two pins 13. Vertical plate 12 welds spring 3 on the lower surface of upper top plate 11, and spring 3 can be selected tower spring for use. The lower end of the spring 3 welds the sensor cover 4. When the acoustic emission sensor 5 is fixed, the sensor cover 4 just covers the upper end of the acoustic emission sensor 5, and the tower spring evenly transfers the fixing pressure to the sensor cover at the top of the acoustic emission sensor. superior. The reaction force of the fixed sensor is first transmitted from the upper top plate of the steel plate bending part to the plastic foot cover, and then the plastic foot cover is transmitted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com