Online dynamic forecast method for polypropylene fusion index

A melt index and polypropylene technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as difficulty in online operation, poor practicability, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

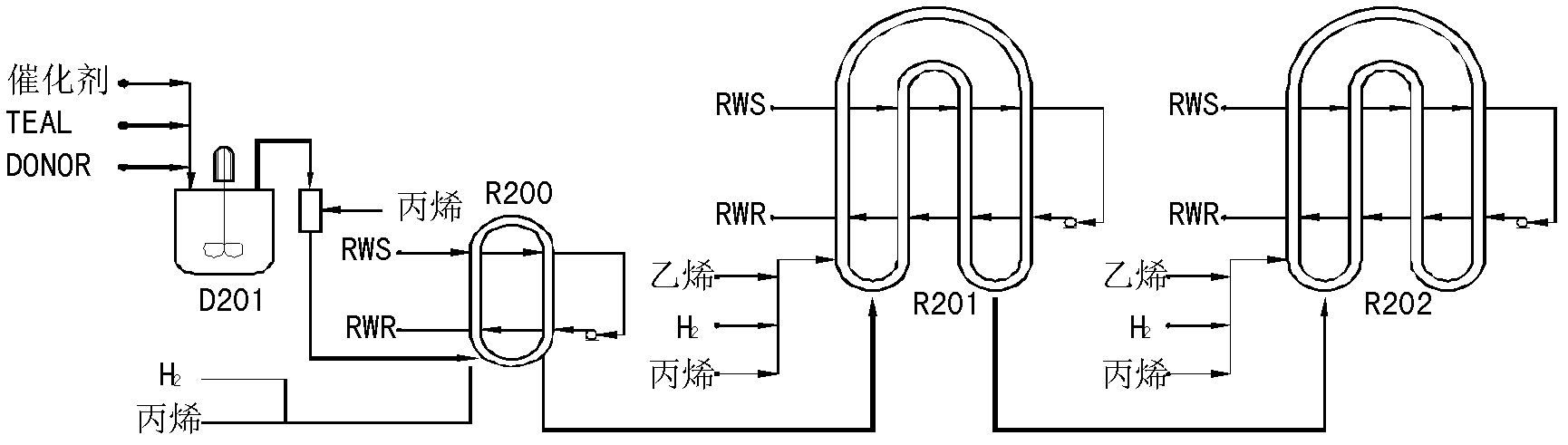

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

[0045] An online dynamic forecasting method for polypropylene melt index, said forecasting method comprising the steps of:

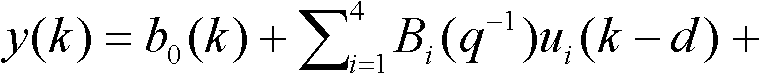

[0046] 1), establish the parameter model structure of the Q-order discrete form of the polypropylene melt index, see formula (1):

[0047]

[0048]

[0049]

[0050]

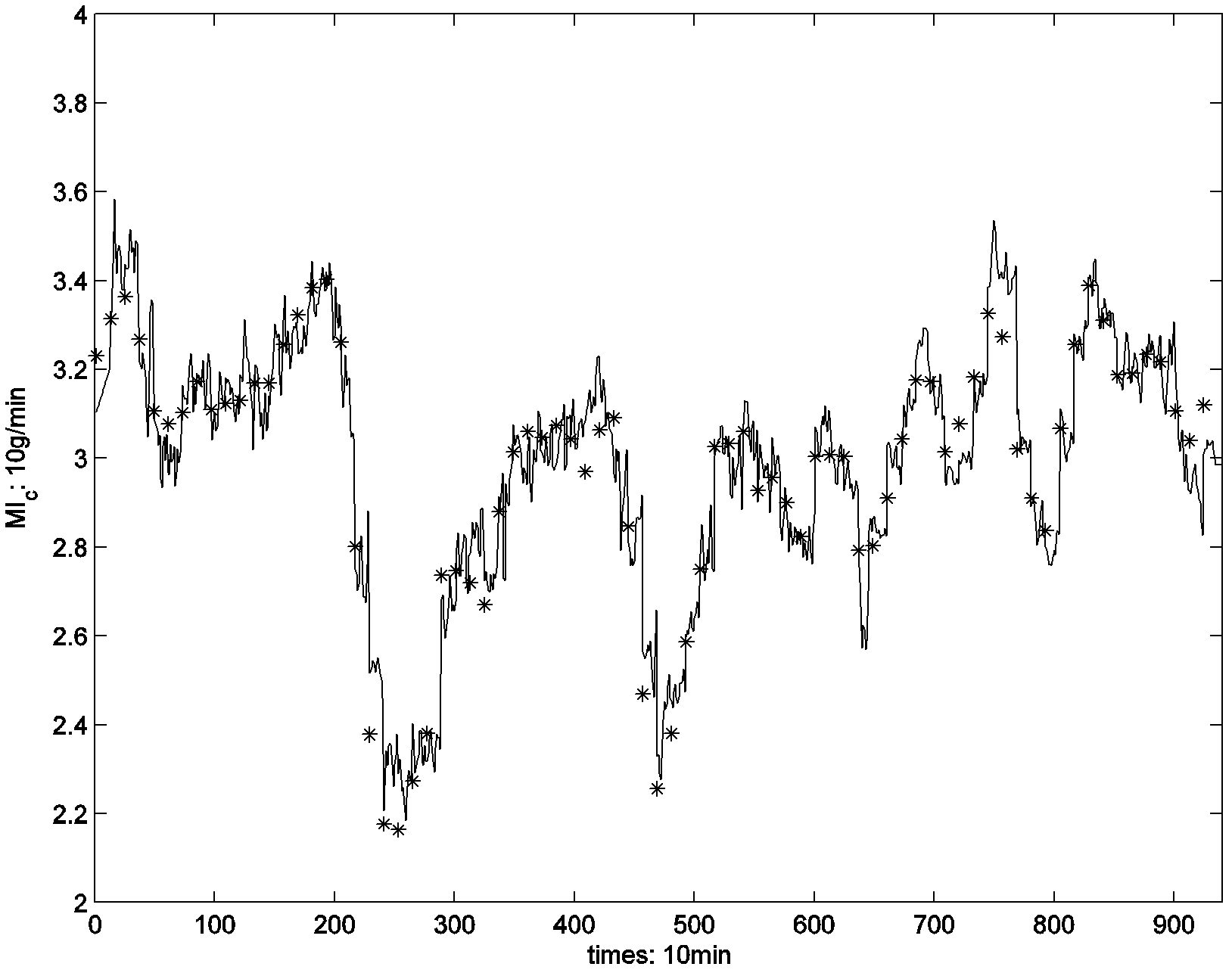

[0051] Wherein, the positive integer Q is the order of the model formula (1); b 0 (k) is an unknown parameter, which is obtained by identification and calculation of step 3) of this step; y(k) is the polypropylene melt index at the kth moment; u 1 (k-d) and u 2 (k-d) represent respectively the ratio of the hydrogen input amount of the k-d moment polymerization unit 1# pipe and the ratio of the propylene input amount and the polymerization reaction temperature; u 3 (k-d) and u 4 (k-d) represent respectively the ratio of the hydrogen input amount of the 2# pipe of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com