Passive permanent magnet coupling transmission, braking or load device

A technology of permanent magnetic coupling and load device, applied in the direction of asynchronous induction clutch/brake, electromechanical device, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

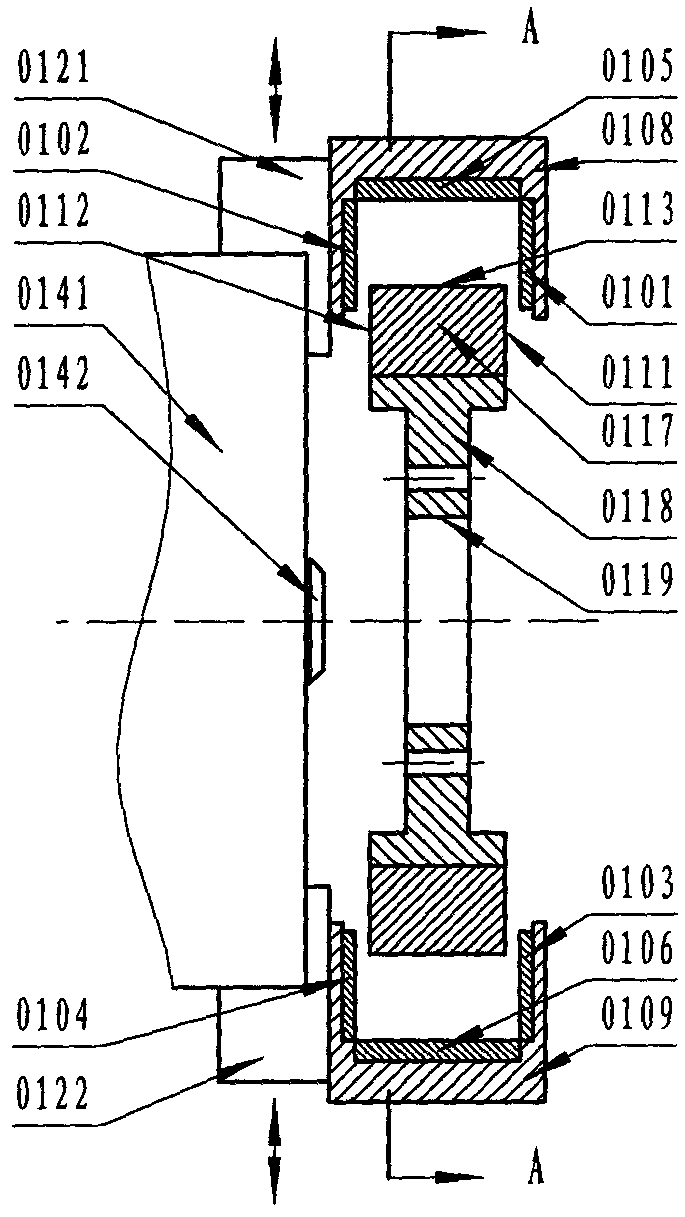

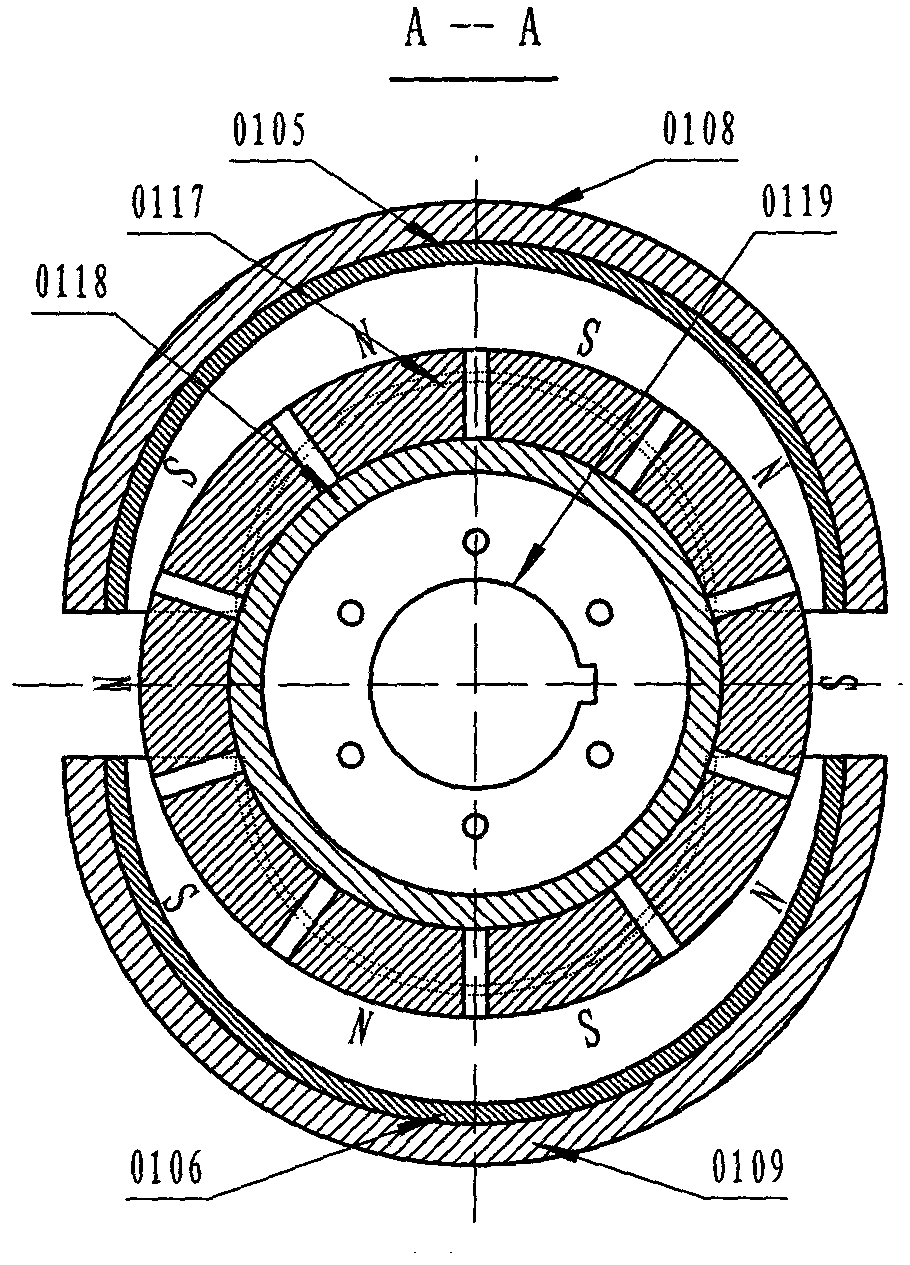

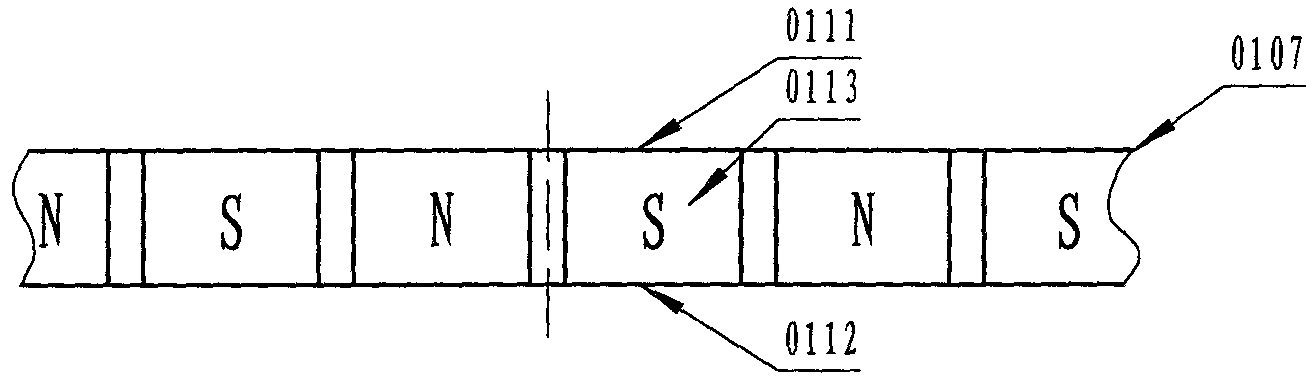

[0088] Example 1. As Figure 1 to Figure 10 As shown, it is a permanent magnet coupling governor (PMD) with a dual petal-shaped axial-radial magnetic field compound structure, which is mainly assembled from the following components: four pairs of axial magnetic field petal-shaped metal conductor armature discs (0101, 0102, 0103, 0104), two pairs of radial magnetic field petal-shaped metal conductor armature disks (0105, 0106), one pair of disc-shaped permanent magnet disks with 3 coupling surfaces (0111, 0112, 0113) ( 0117), a pair of active rotor disc coupling mechanisms consisting of a disc-shaped permanent magnet group mounting plate (0118) and its shaft hole (0119), a pair of two petal-shaped metal conductor armature mounting plates (0108, 0109 ), two chuck claws (0121, 0122), the chuck body (0141) and the central short shaft (142) constitute the passive rotor disc coupling mechanism, and two petal-shaped metal conductor armature mounting discs (0108, 0109) Fasten and ins...

Embodiment 2

[0090] Example 2. If Figure 11 to Figure 14 As shown, it is a permanent magnet coupling governor (PMD) with a dual petal-shaped axial-radial magnetic field compound structure, which is mainly assembled from the following components: four pairs of axial magnetic field petal-shaped metal conductor armature discs (0201, 0202, 0203, 0204), two flap-shaped squirrel-cage armature disks (0205, 0206), one disk-shaped permanent magnet disk (0217) with 3 coupling surfaces (0211, 0212, 0213), One pair of active rotor disk coupling mechanism consisting of disk-shaped permanent magnet group mounting plate (0218) and its shaft hole (0219), one pair of two petal-shaped composite armature mounting plates (0208, 0209), two Chuck jaws (0221, 0222), chuck body (0241) and central short shaft (242) constitute the passive rotor disk coupling mechanism, and two petal-shaped composite armature mounting disks (0208, 0209) are respectively connected with two chucks. The disc claws (0221, 0222) are fa...

Embodiment 3

[0091] Example 3. As Figure 15 to Figure 18As shown, it is a permanent magnetic coupling governor with a double petal-shaped axial-radial magnetic field compound structure, which is mainly assembled from the following components: four petal-shaped pot grate armature discs (0301, 0302, 0303 , 0304), two flap-shaped squirrel-cage armature discs (0305, 0306), a disc-shaped permanent magnet disc (0317) with three coupling surfaces (0311, 0312, 0313), a disc-shaped The active rotor disk coupling mechanism composed of the permanent magnet group mounting plate (0318) and its shaft hole (0319), a pair of two petal-shaped composite armature mounting plates (0308, 0309), two chuck claws (0321, 0322), the chuck body (0341) and the central short shaft (0342) constitute the passive rotor disc coupling mechanism, the radial displacement component is a "seesaw" type, mainly composed of L-shaped seesaws (0351, 0352), chuck body ( 0341), chuck jaws (0321, 0322), mobile connection plate (0367...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com