Surface-treating composition, and surface-treated steel sheet

A technology of surface treatment and composition, which is applied in the field of surface treatment steel plates, can solve the problems of impossible surface treatment of steel plates and poor appearance, and achieve excellent adhesion, heat discoloration resistance, excellent scratch resistance, and excellent heat resistance discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

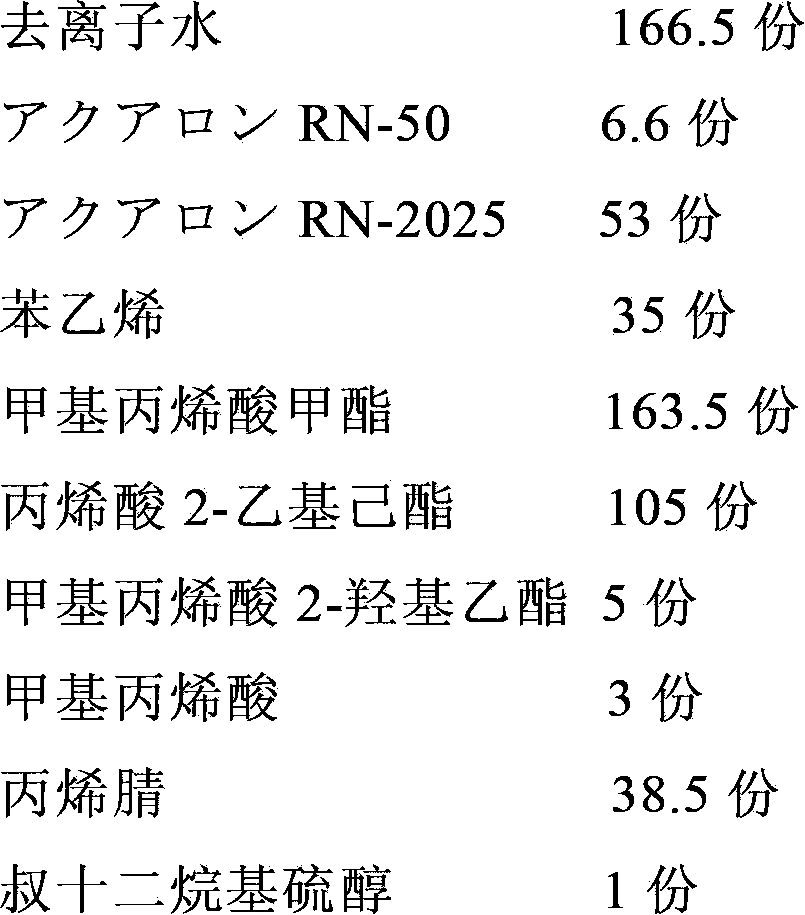

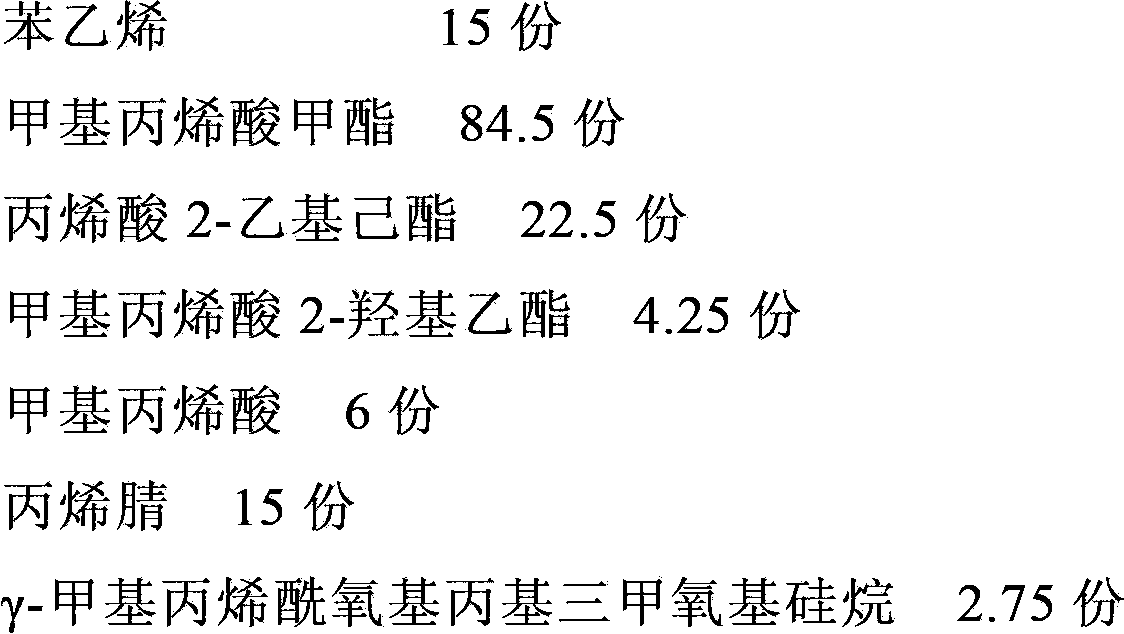

Method used

Image

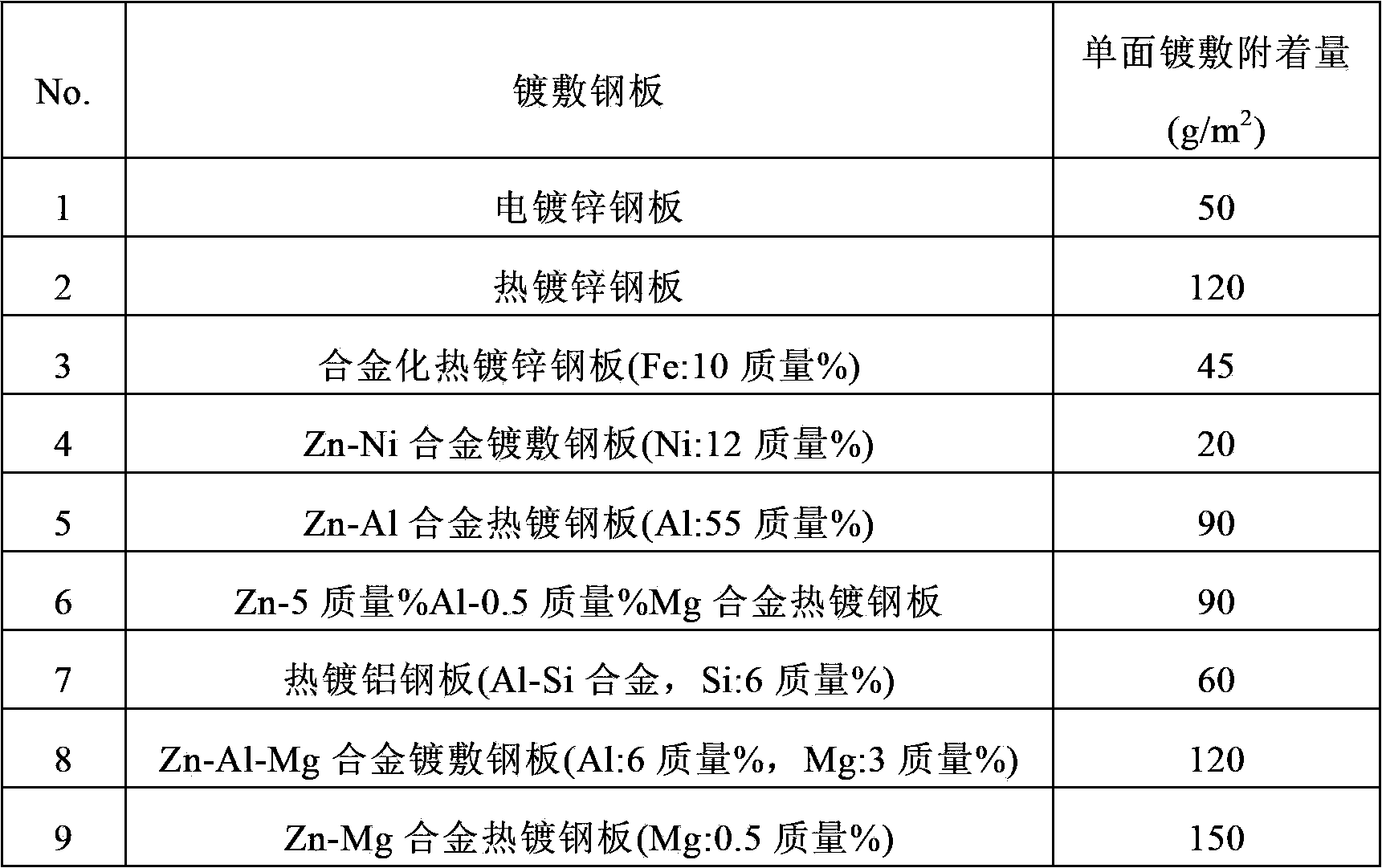

Examples

Embodiment

[0135] The titanium-containing aqueous solution (A) and components (B) to (F) used in the surface treatment composition are shown below.

[0136] [Manufacture of titanium-containing aqueous solution (A)]

manufacture example 1

[0137] Manufacturing example 1 (titanium-containing aqueous solution T1)

[0138] 5 ml of 60% by mass titanium tetrachloride solution was adjusted to 500 ml with distilled water, and ammonia water (ammonia:water mass ratio was 1:9) was added dropwise to the resulting solution to precipitate low condensation products of titanium hydroxide. After washing with distilled water, 10 ml of a 30% by mass hydrogen peroxide aqueous solution was added and stirred to obtain a titanium-containing yellow translucent, viscous titanium-containing aqueous solution T1.

manufacture example 2

[0139] Manufacturing example 2 (titanium-containing aqueous solution T2)

[0140] A mixture of 10 parts by mass of titanium tetraisopropoxide and 10 parts by mass of isopropanol was added dropwise to 10 parts by mass of a 30 mass % hydrogen peroxide aqueous solution and 100 parts by mass of in a mixture of deionized water. Then, it was aged at 25°C for 2 hours to obtain a transparent yellow, slightly viscous titanium-containing aqueous solution T2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com