Infrared sensor

An infrared sensor and infrared technology, applied in the direction of instruments, scientific instruments, electric radiation detectors, etc., can solve the problems of increasing the distance of heat-sensitive elements, high heat conduction, and high price, so as to improve thermal responsiveness and detection sensitivity, expand The effect of detection area, small size and fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

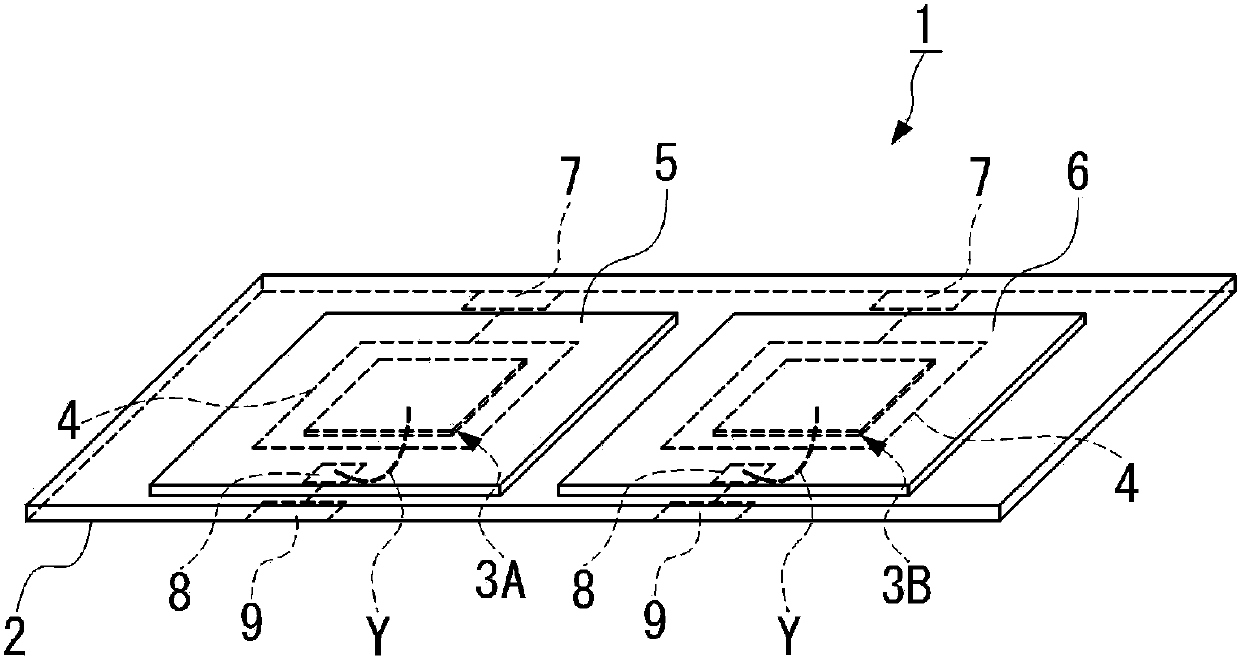

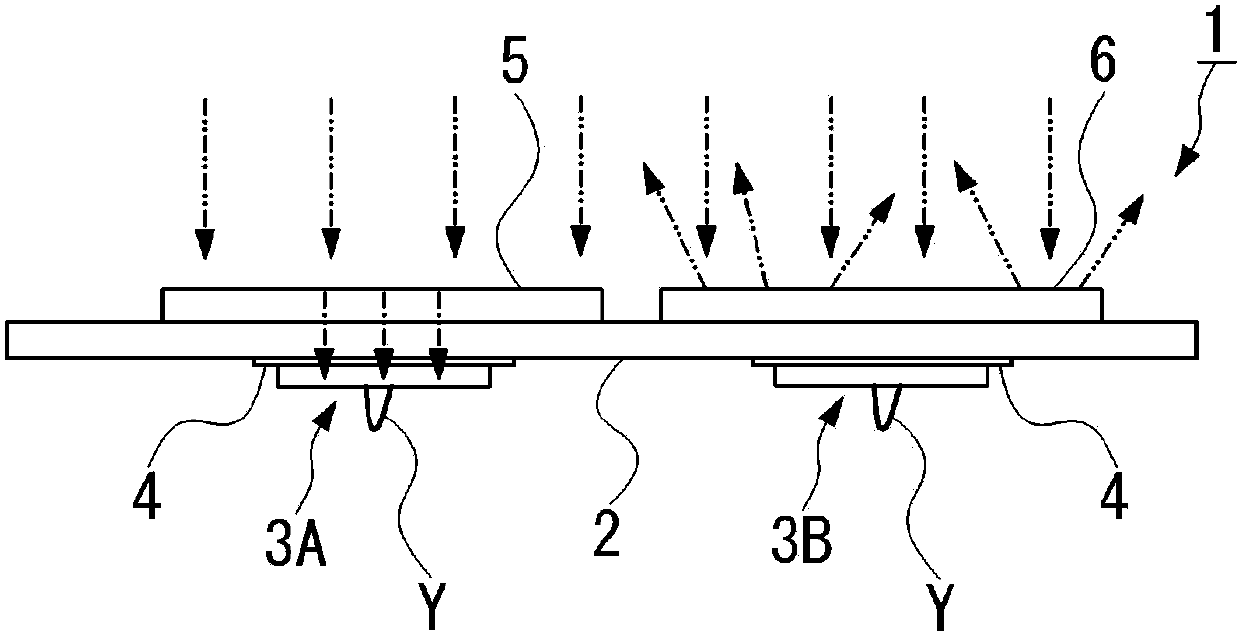

[0034] Below, refer to Figure 1 to Figure 4 A first embodiment of the infrared sensor according to the present invention will be described. In addition, in each drawing used in the following description, the scale is appropriately changed in order to make each member recognizable or easily recognizable in size.

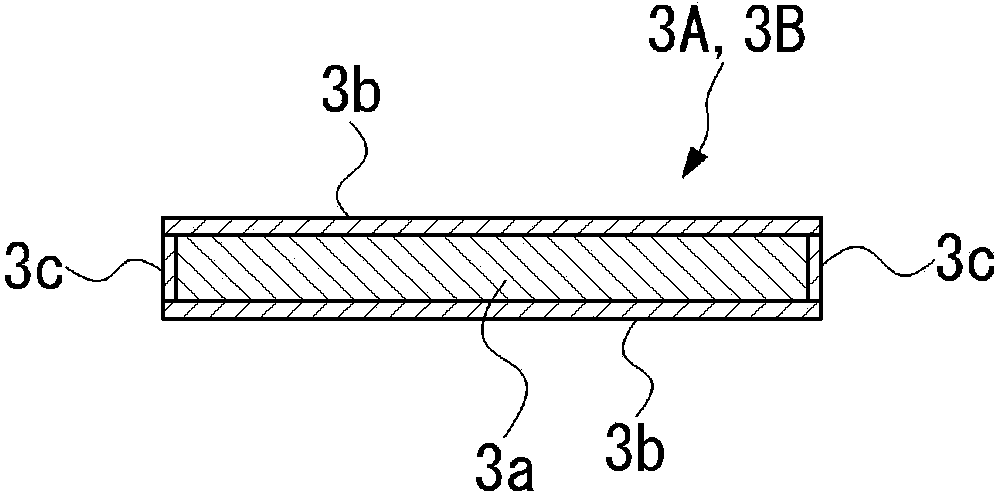

[0035] Such as figure 1 and figure 2 As shown, the infrared sensor 1 of the present embodiment is provided with: an insulating film 2; a first thermosensitive element 3A and a second thermosensitive element 3B, which are spaced apart from each other on one side (lower surface) of the insulating film 2; For the bonding electrode 4, the first thermosensitive element 3A and the second thermosensitive element 3B are respectively bonded on one side of the insulating film 2 by patterns such as copper foil; the infrared absorbing film 5 is connected with the first thermosensitive element 3A. facing and provided on the other surface (upper surface) of the insulating film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com