Travelling type automatic multifunctional field operation machine

A multi-functional, driving-type technology, applied in the chassis of agricultural machinery, agricultural machinery and machinery, agriculture, etc., can solve the problems of farmers' liberation, detrimental to farmers' health, unable to promote agricultural automation production, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This driving-type automatic multifunctional field operation machine includes a track, a driving frame and an operating system. The driving frame is placed on the track, the operating system is installed on the driving frame, and various agricultural implements are installed at the bottom of the operating system.

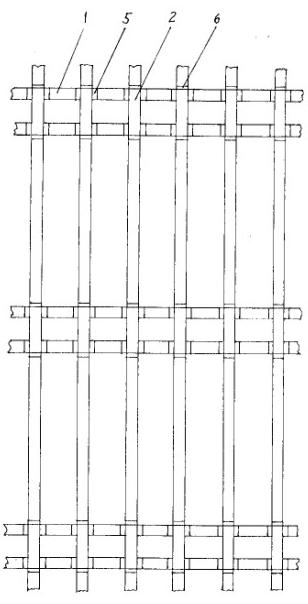

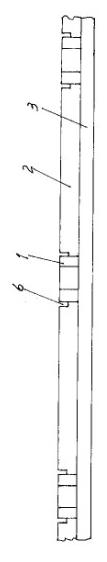

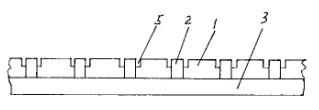

[0025] exist figure 1 , figure 2 and image 3 Among them, the track includes a horizontal shunting track 1 and a vertical operating track 2, which are perpendicular to each other and arranged crosswise. Parallel and equally spaced, the distance between the working tracks 2 is equal to the distance between the working wheels 17 at the bottom of the driving frame, and the shunting track 1 is double-lined, and the distance between the two lines is equal to the shunting running at the lower part of the driving frame. The distance between the wheels 4, the height of the upper surface of the shunting track 1 and the working track 2 is equal and horizontal, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com