Propulsion screw rod for bulking machine

A technology of propulsion screw and extruder, applied in the direction of chemical instruments and methods, chemical/physical processes, and methods of chemically changing substances by using atmospheric pressure, which can solve problems such as increased manufacturing costs, need to disassemble, and inconvenient operation, and achieve The effect of long service life, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

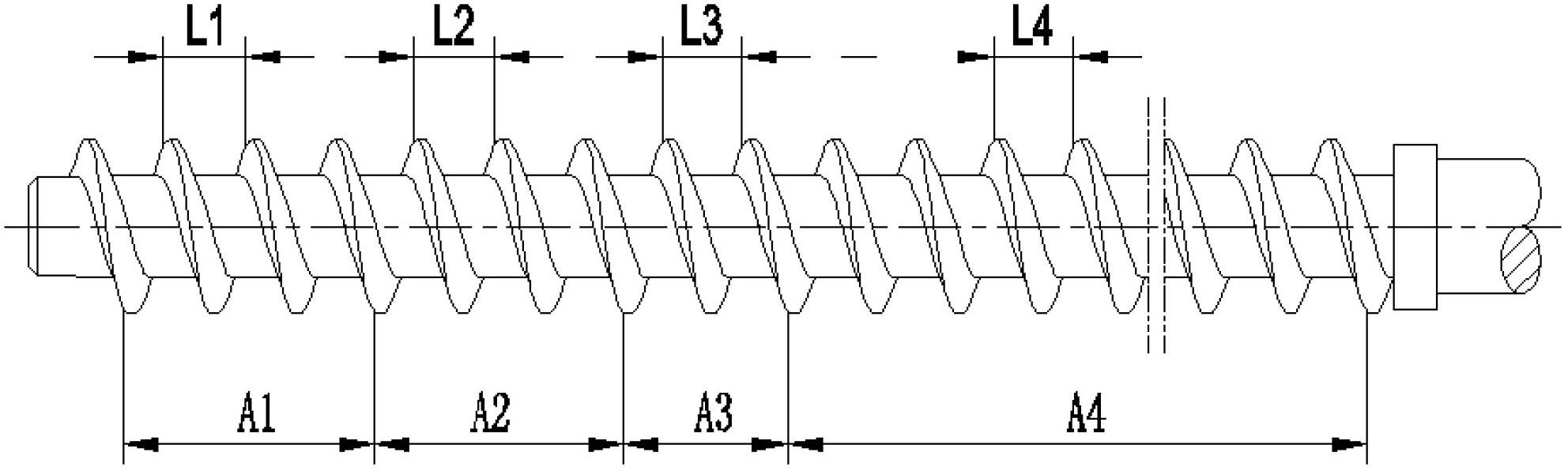

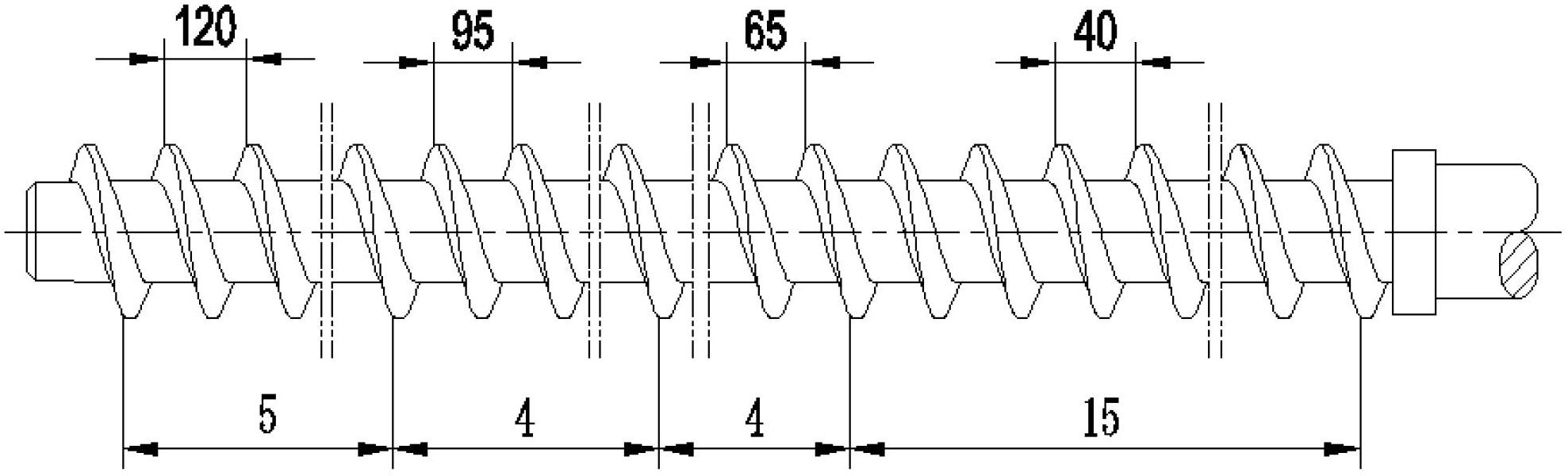

[0029] as attached figure 2 As shown, in December 2011, the propulsion screw of the extruder designed by the inventor was used in a workshop. The propulsion screw was divided into 4 sections, wherein the pitch L1 of the first section was 120 mm, and the number of spiral turns A1 was 5; The pitch L2 of the second stage is 95 mm, and the number of spiral turns A2 is 4; the pitch L3 of the third stage is 65 mm, and the number of spiral turns A3 is 4; the pitch L4 of the fourth stage is 40 mm, and the number of spiral turns A4 is 15 One, after 5 months of trial, the puffing effect is remarkable.

Embodiment 2

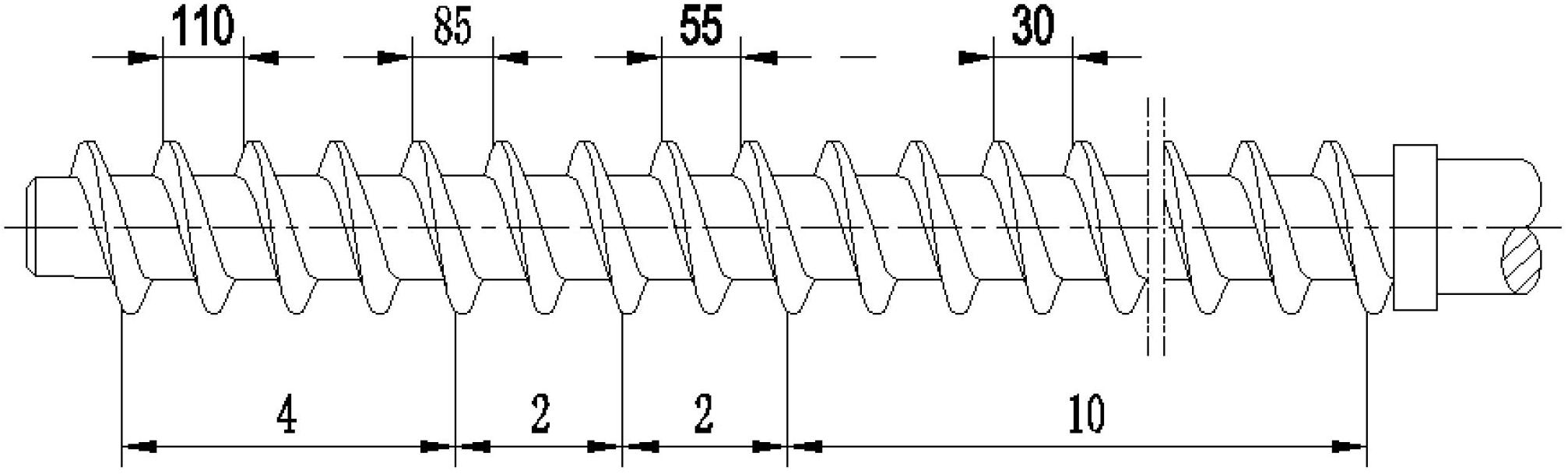

[0031] as attached image 3As shown, in December 2011, the propulsion screw of the extruder designed by the inventor was used in the third workshop. The propulsion screw is divided into 4 sections, wherein the pitch L1 of the first section is 110 mm, and the number of spiral turns A1 is 4; The pitch L2 of the second stage is 85 mm, and the number of spiral turns A2 is 2; the pitch L3 of the third stage is 55 mm, and the number of spiral turns A3 is 2; the pitch L4 of the fourth stage is 30 mm, and the number of spiral turns A4 is 10 One, tried for 5 months, the puffing effect is remarkable.

Embodiment 3

[0033] as attached Figure 4 As shown, in January 2012, the propulsion screw of the extruder designed by the inventor was used in the second workshop. The propulsion screw is divided into 4 sections, wherein the pitch L1 of the first section is 115 mm, and the number of spiral turns A1 is 4; The pitch L2 of the second stage is 90 mm, and the number of spiral turns A2 is 2; the pitch L3 of the third stage is 60 mm, and the number of spiral turns A3 is 2; the pitch L4 of the fourth stage is 36 mm, and the number of spiral turns A4 is 13 One, in the past 4 months of production, the puffing effect is remarkable, and the product has been praised by users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com