a blender

A blender and stirring mill technology, applied in the field of blenders, can solve problems such as incomplete crushing of the ingredients being stirred, bottlenecks in the life of the bearings, impact on nutritional value, etc., to reduce vibration and noise, improve aesthetics, and retain more nutrients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

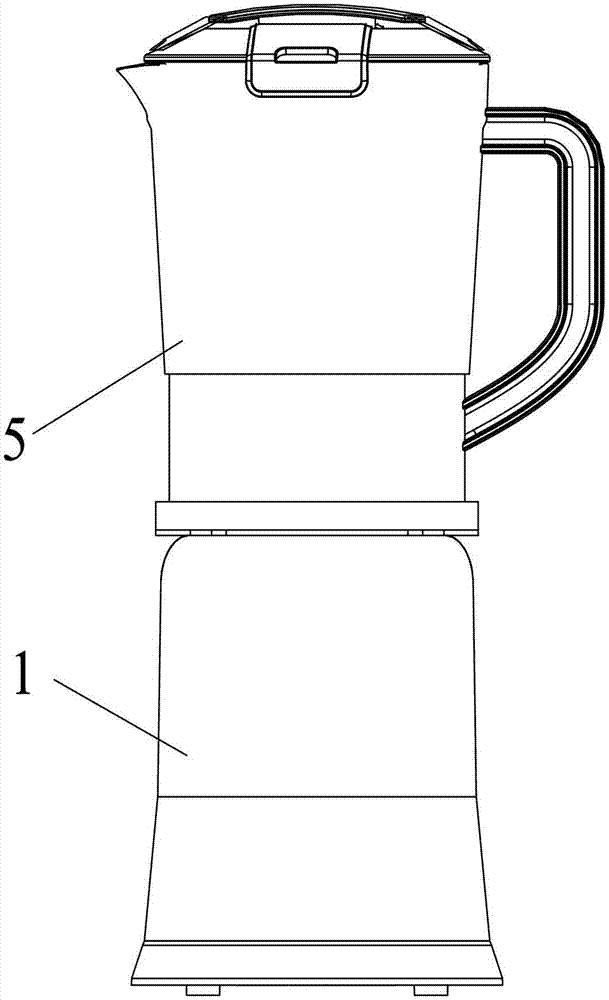

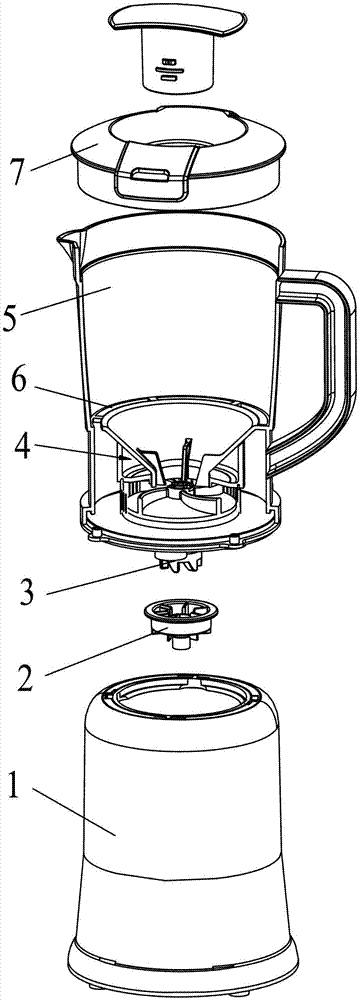

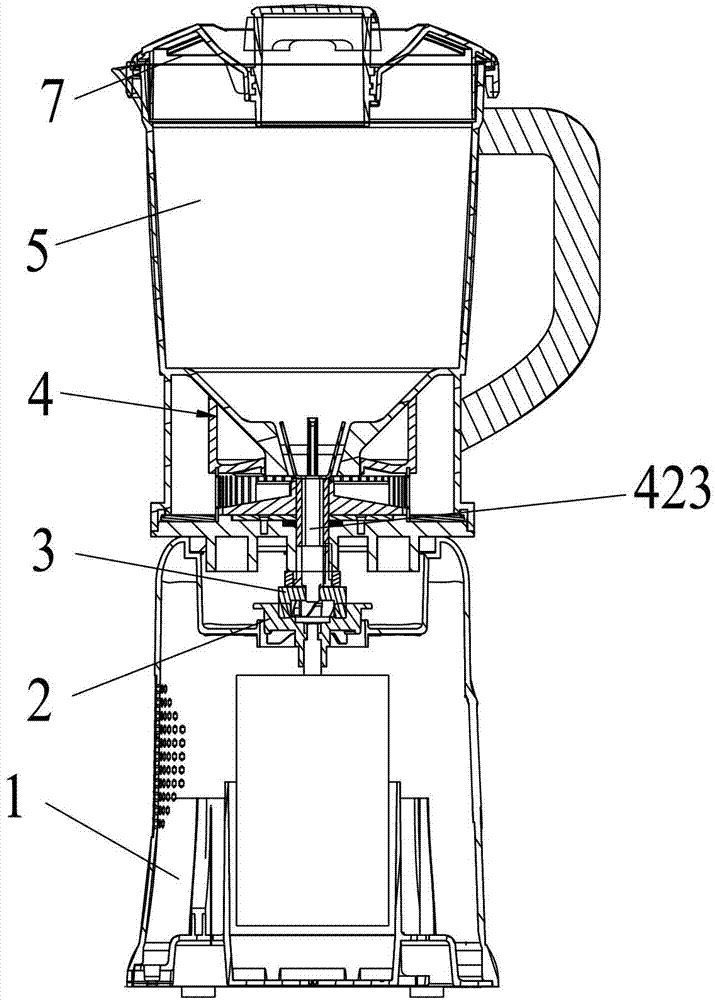

[0029] Such as Figure 1 to Figure 1 As shown in 0, the present invention discloses a mixer, which includes a main engine 1 providing power input, a stirring cup 5 and a stirring mill structure 4, the stirring mill structure 4 is arranged in the stirring cup 5, and the output shaft of the main engine 1 passes through the stirring cup 5. The bottom is connected to the stirring mill structure 4. The stirring mill structure 4 includes a filter assembly and a knife assembly matched therewith. The filter assembly includes a material inlet 411, a filter screen 412 and a knife seat 413. Located at the upper end, the knife seat 413 is located at the lower end, and the filter screen 412 is tightly connected between the feed port 411 and the knife seat 413 , the knife assembly is arranged on the knife seat 413 , and the knife assembly is located in the filter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com