Separatory funnel

A separatory funnel and funnel technology, applied in the direction of funnel, liquid treatment, bottle filling, etc., can solve the problems of explosion, troublesome operation, affecting the experiment, etc., and achieve the effect of ensuring the safety of the experiment, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

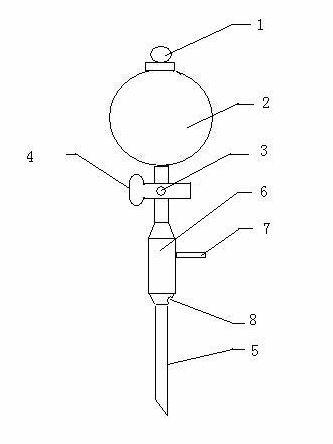

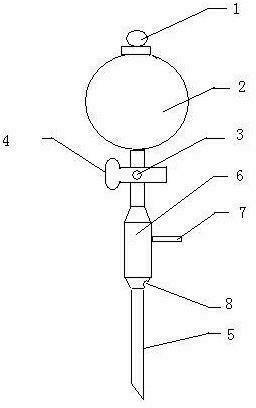

[0012] Such as figure 1 A separatory funnel, the separatory funnel comprises a plug 1, a spherical bucket body 2, a piston 3, a piston cavity 4 and a drain tube 5, the top of the drain tube 5 is connected to the spherical bucket body 2, and the piston cavity 4 is fixedly connected to the bottom of the drain tube 5 In the middle and upper part, the piston 3 is inserted into the piston cavity 4 and connected seamlessly with the piston cavity 4. A sleeve 6 is arranged on the outer side of the leakage tube 5 below the piston cavity 4. The sleeve 6 is flexibly connected with the leakage tube 5. The upper part of the sleeve 6 is provided with an air branch pipe. 7. An air inlet 8 is arranged on the lower wall of the casing 6 .

[0013] The piston chamber 4 is formed by fixed connection of two coaxial cylinders with different diameters, and the axis of the piston chamber intersects the drain pipe perpendicularly.

[0014] The diameter of the casing 6 is greater than that of the leak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap