Intelligent dust collection system and filler bin of intelligent dust collection system applying same

A dust collection system and powder silo technology, applied in the direction of dust removal, cleaning methods and utensils, packaging, etc., can solve the problems of springs and other moving parts that are easy to rust, pressure safety valves that cannot be opened, and pressure safety valves that are out of order. The effect of frequent start-up, avoiding failure, and avoiding dust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

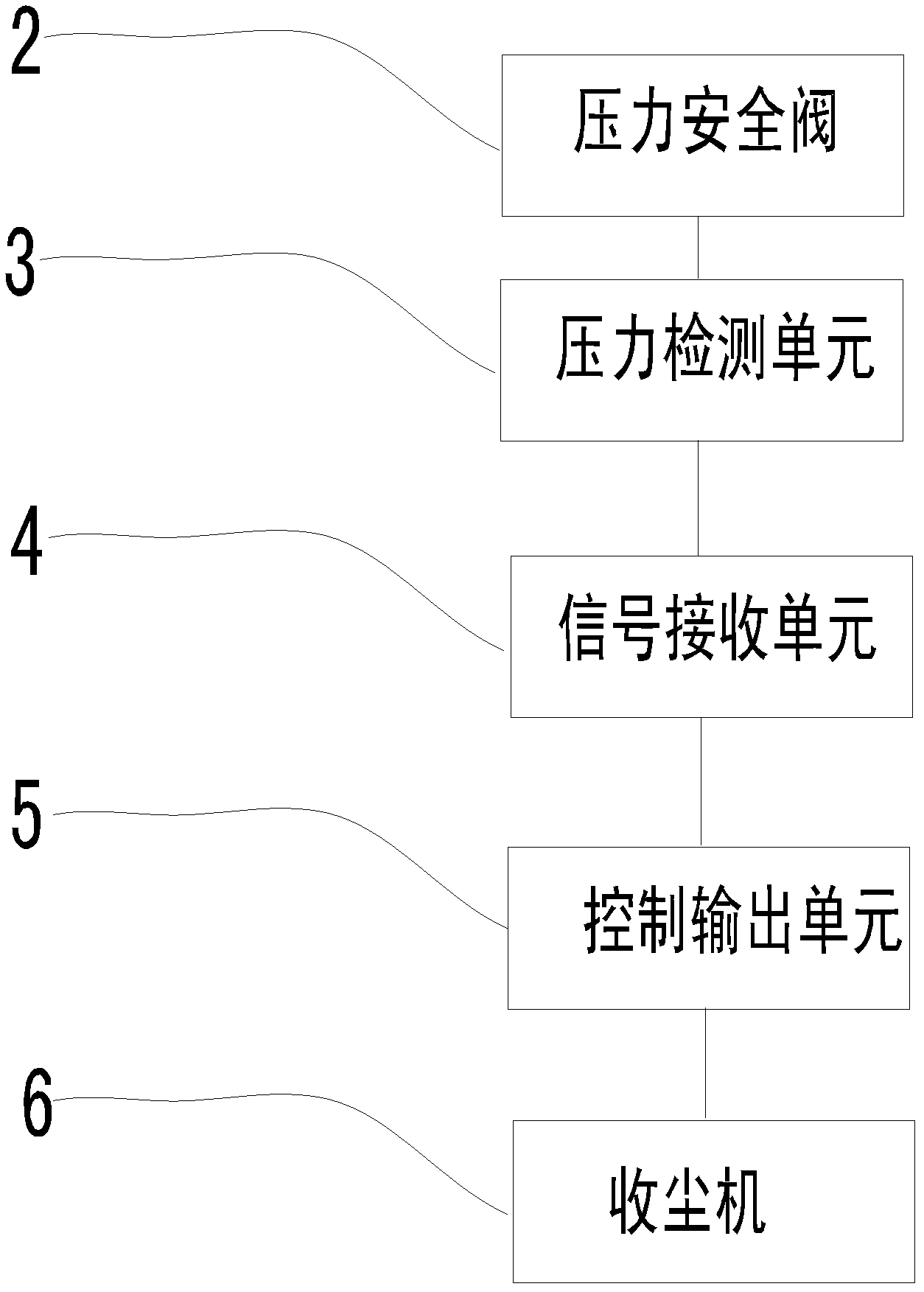

[0025] Such as figure 1 As shown, the intelligent dust collection system of the present invention includes a pressure safety valve 2, a pressure detection unit 3, a signal receiving unit 4, a control output unit 5 and a dust collector 6 connected in sequence and forming a control circuit; the signal receiving unit 4 and the control output The unit 5 is combined into a control unit; the pressure detection unit 3 is used to detect the pressure value of the pressure safety valve 2; the signal receiving unit 4 presets the pressure value and is electrically connected with the pressure detection unit 3 to receive the pressure detected by the pressure detection unit 3 Real-time pressure value; one end of the control output unit 5 is electrically connected to the signal receiving unit 4, and the other end is electrically connected to the dust collector 6, and the control output unit 5 compares the real-time pressure value detected by the pressure detection unit 3 with the preset pressu...

Embodiment 3

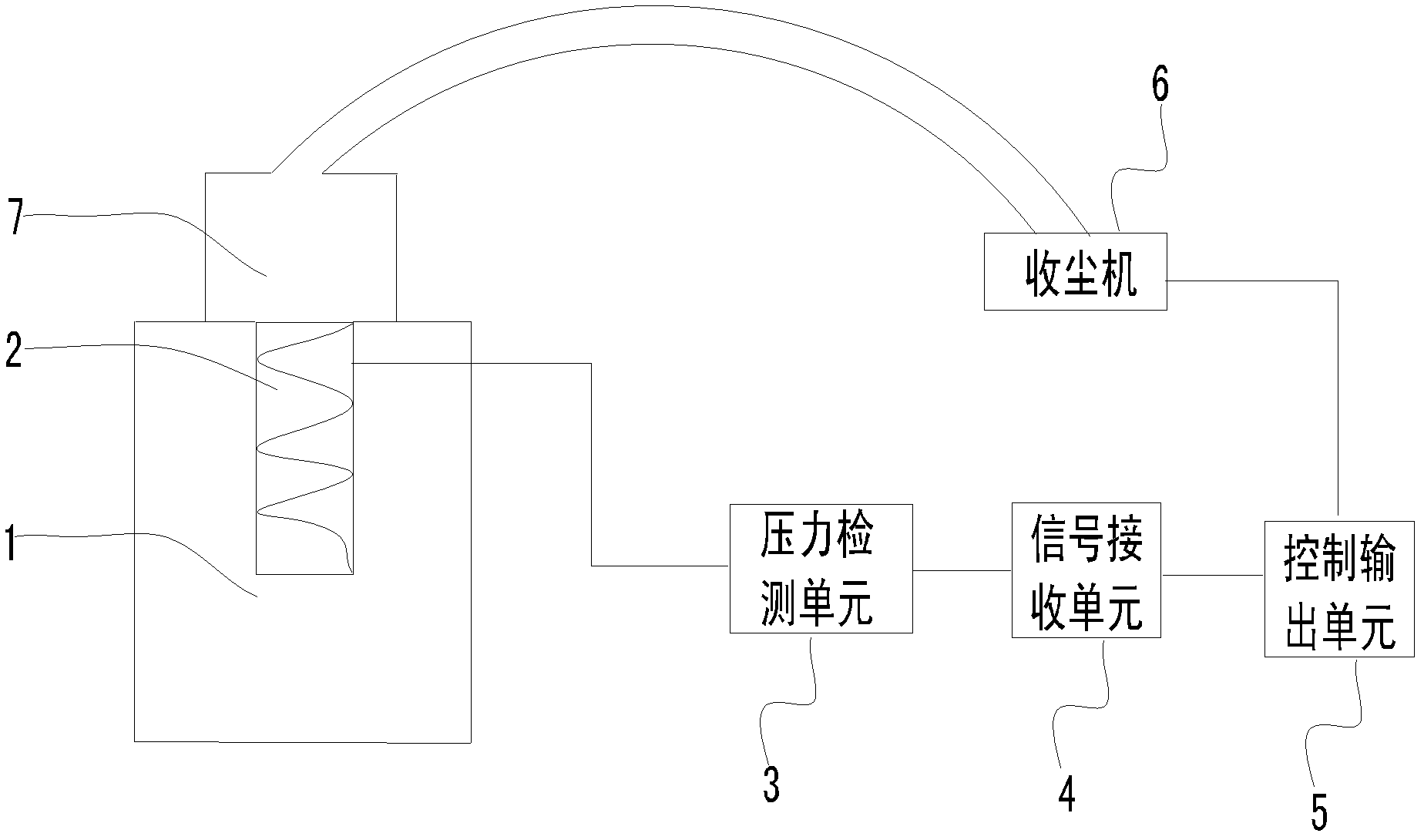

[0029] Such as figure 2 As shown, the powder silo of the present invention includes a silo body 1, a protective cover 7 with vents, and the intelligent dust collection system described in Embodiment 1; the pressure safety valve 2 is installed on the top of the silo body 1, and makes the entire silo body 1 is still sealed, and the pressure safety valve 2 decides whether to open the pressure relief according to the real-time pressure in the warehouse body 1; the protective cover 7 is installed on the top of the warehouse body 1, and can cover the pressure safety valve 2. In other embodiments, the pressure safety valve 2 can also be installed on the side of the bin body 1, and correspondingly, the protective cover 7 is also installed on the side; the dust collector 6 is installed on the ground, and is ventilated with the protective cover 7. The mouth is connected. It works as follows:

[0030] The pressure value that the bin body 1 can withstand is certain, and the signal rece...

Embodiment 4

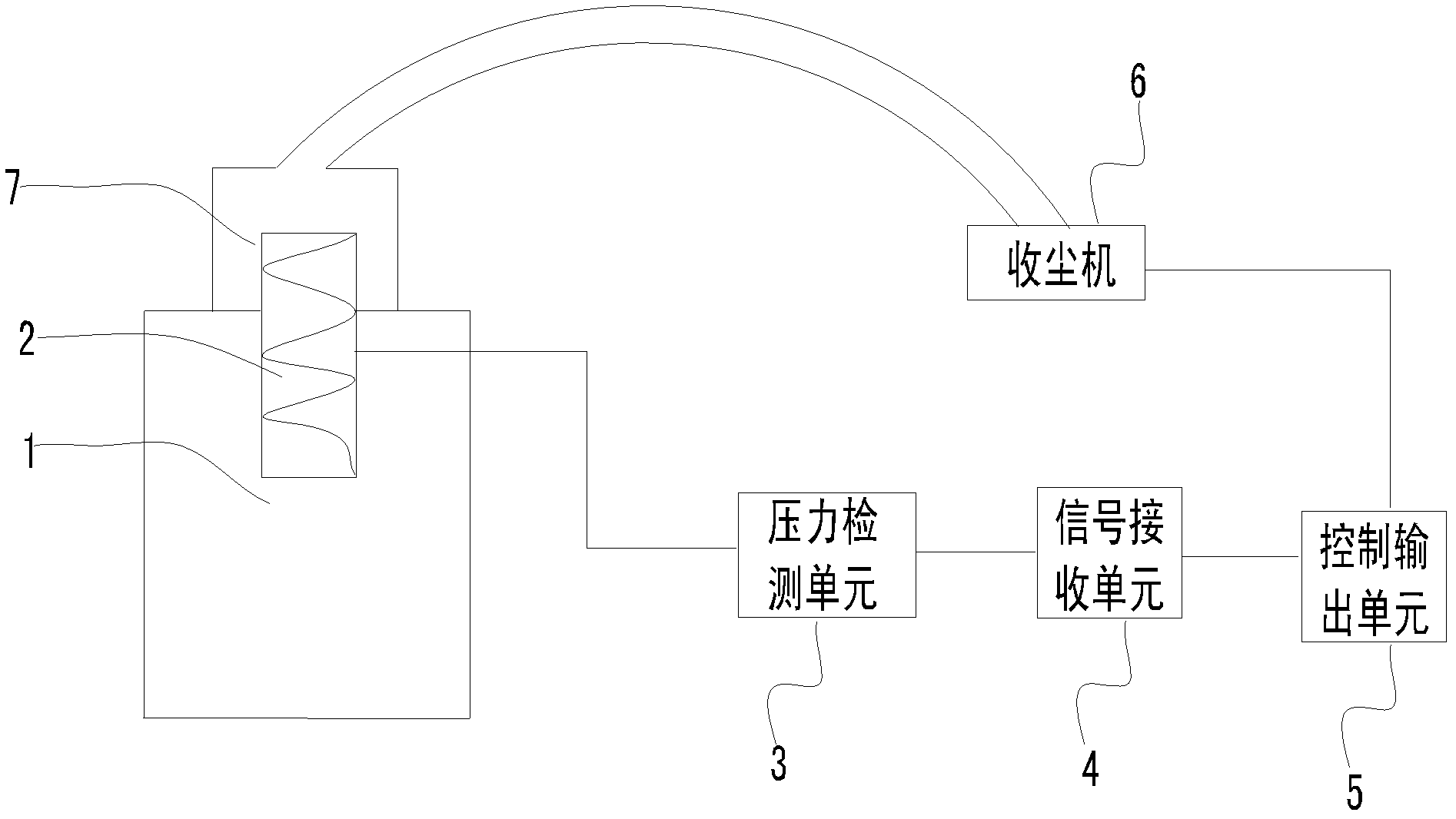

[0033] The difference from the third embodiment is that the intelligent dust collection system described in the second embodiment is applied to the powder silo, such as Figure 4 shown. The pressure safety valve 2 is installed on the bin body 1, and the pressure value that the bin body 1 can withstand is certain. As the powder in the bin body 1 of the powder bin increases, the real-time pressure in the bin body 1 increases. When the real-time pressure value When the pressure value that the bin body 1 can withstand is exceeded, in order to prevent the bin body 1 from being damaged, the pressure safety valve 2 must push against the bin body 1 to release the pressure. circuit is connected, such as Figure 5 As shown, the dust collector 6 starts to work; as the dust in the bin body 1 emerges, the real-time pressure value in the bin body 1 gradually decreases. When the real-time pressure value decreases to the point that the bin body 1 can withstand, the pressure safety valve 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com