Finishing process of stone two/multiple cylinders

A stone and cylinder technology, applied in the field of splicing hollow cylinders with arc-shaped slates, can solve the problems of large input of manpower and material resources, low flexibility, and time-consuming, and achieves the reduction of production costs, the avoidance of potential safety hazards, and the improvement of processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

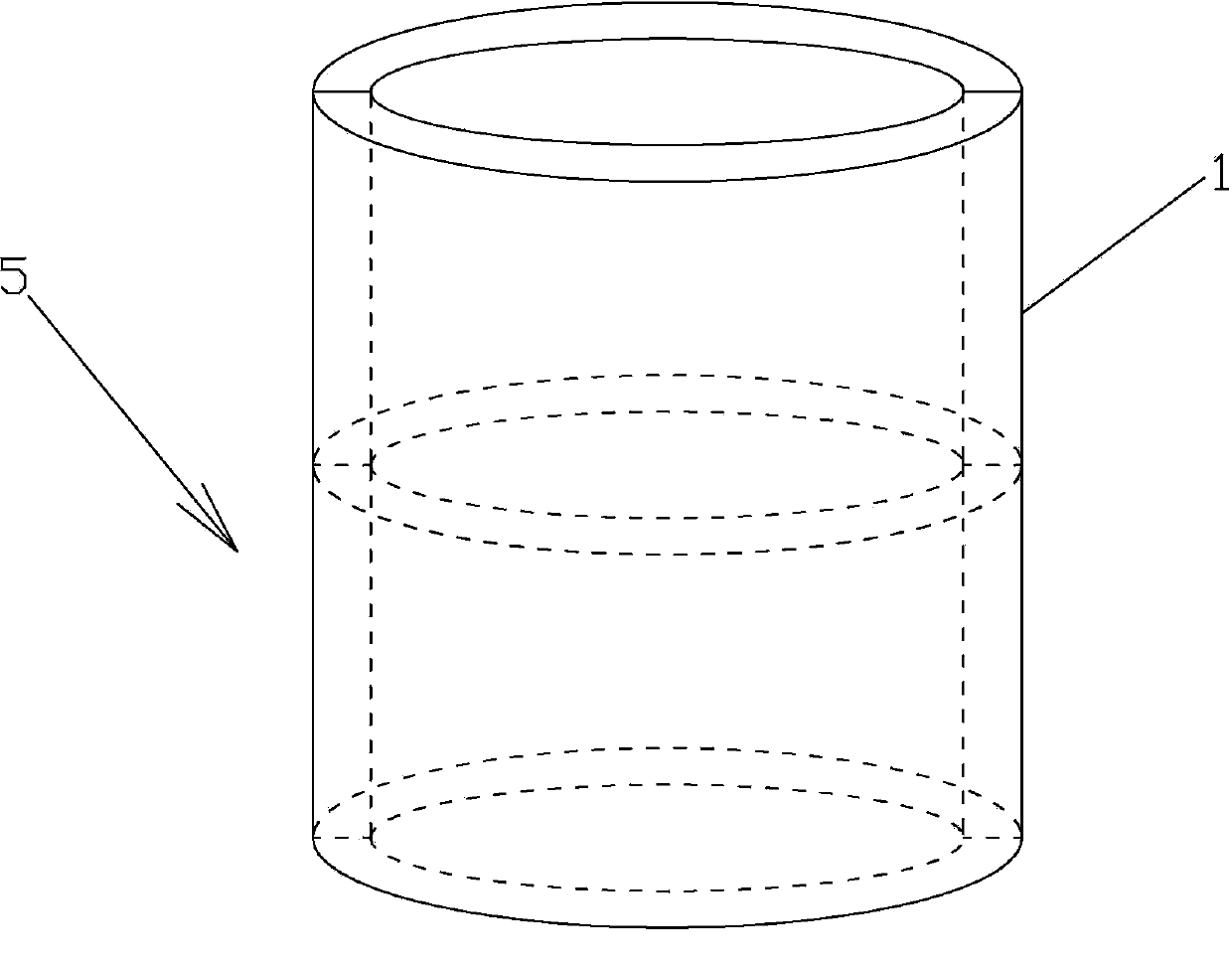

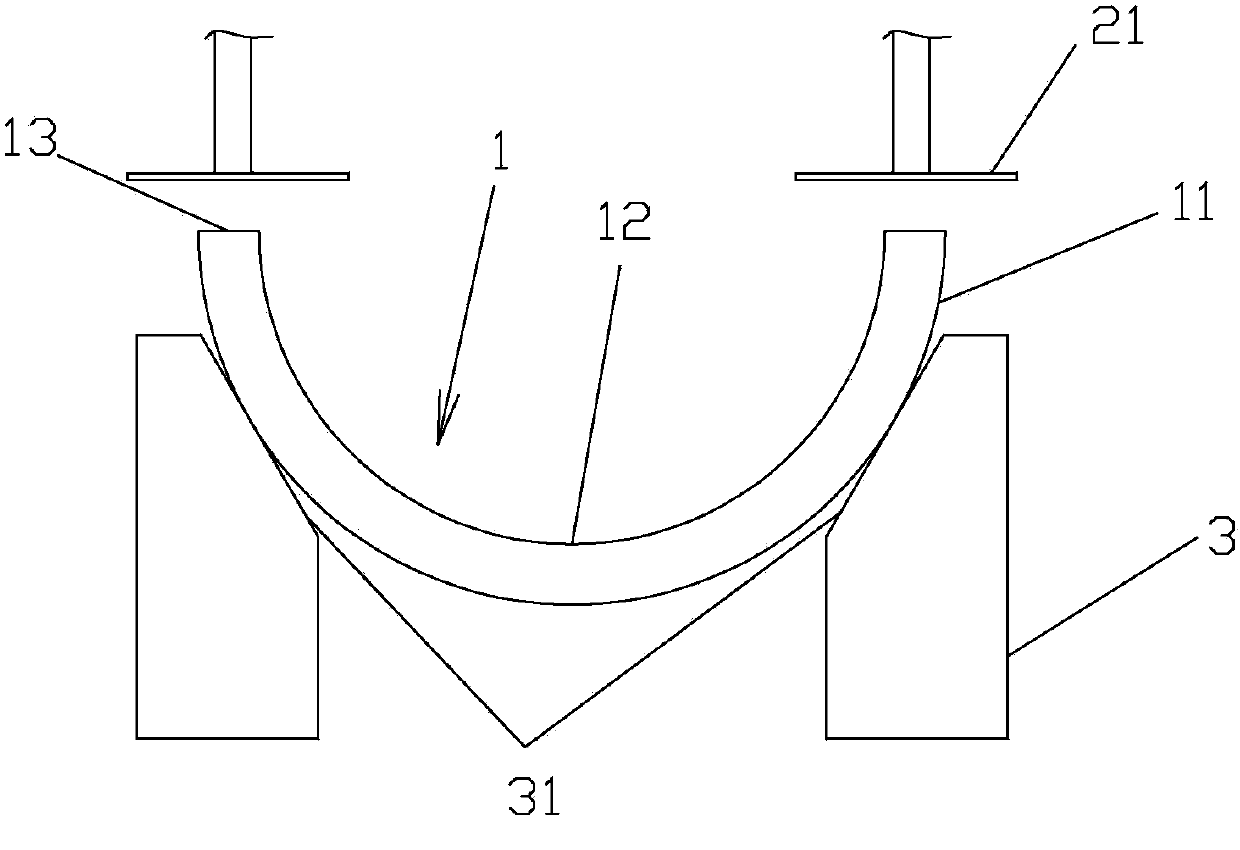

[0029] refer to figure 1 , the finishing process of two stone cylinders, which includes the following steps: a. cutting the stone with a wire machine, and cutting to form a semi-circular arc-shaped slab 1 with a rough surface, filling glue on the inner arc surface 12 of the semi-circular-arc slate 1 and Sticking the mesh to reinforce it; b, first using a coarse grinder to roughly grind the semicircular arc-shaped slate 1, and then using a water mill for water grinding; c, placing the semicircular arc-shaped slate 1 with the inner arc surface 12 facing up on the double-knife bridge cutting On the base 3 of the machine, the base 3 has two matching inverted splayed surfaces 31, and the above-mentioned semi-circular arc-shaped stone slab 1 can be placed horizontally after being placed on the inverted splayed surfaces 31, and then two horizontal cutter heads 21 are used to Simultaneously carry out horizontal cutting to the two axial sides 13 of the semi-circular arc-shaped stone sl...

Embodiment 2

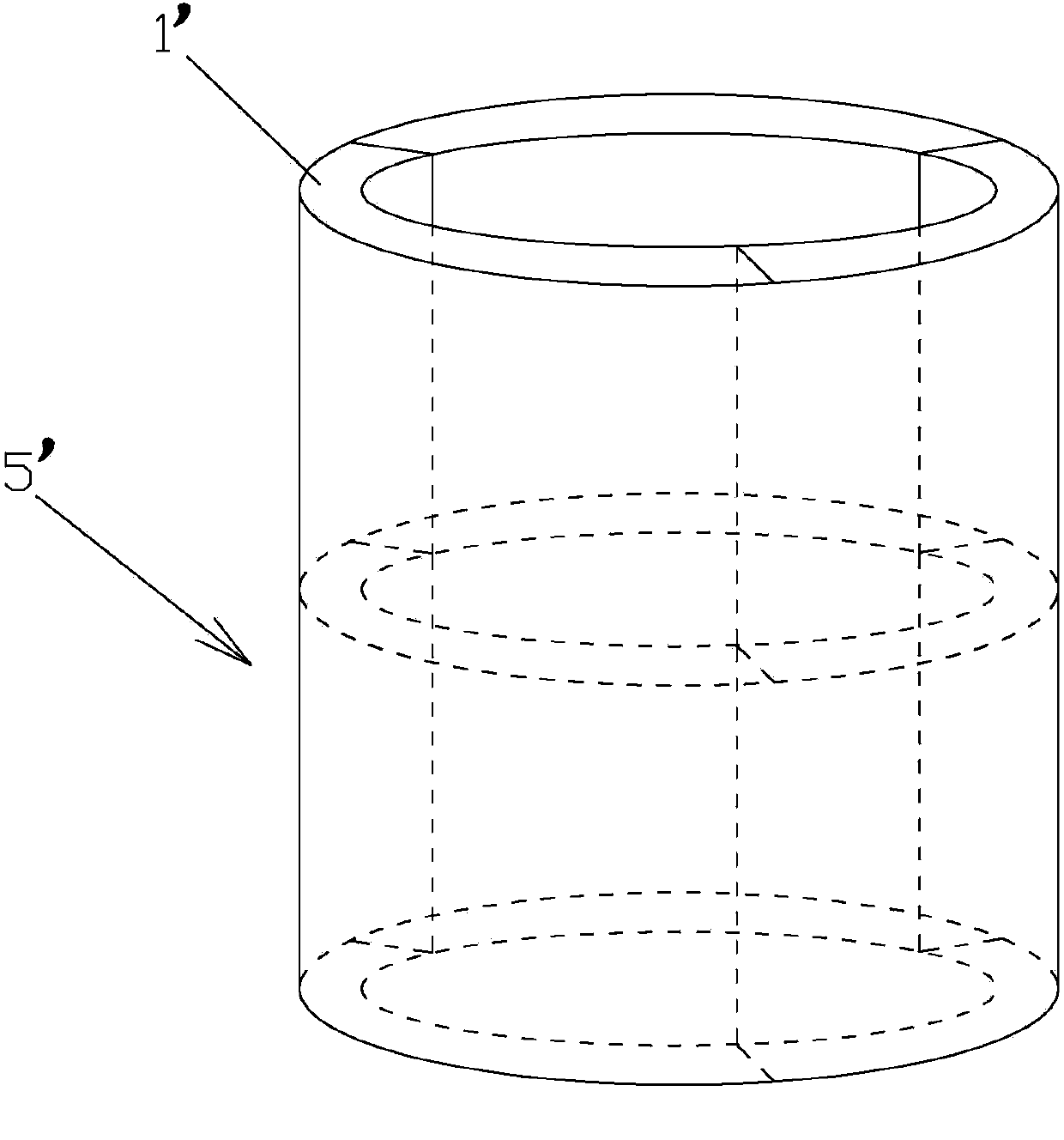

[0032] refer to Figure 7 The processing process of this embodiment is basically the same as that of the above-mentioned embodiment, and the main difference is that this embodiment consists of three 1 / 3 arc-shaped stone plates 1' spliced into a full circle, and then stacked in turn to form a three-piece cylinder 5'.

[0033] Also refer to Figure 5 and Figure 6, the finishing process of multi-piece stone columns, which includes the following steps: a. Cutting stone with a wire machine, and cutting to form a 1 / 3 arc-shaped slate 1' with a rough surface, and 1 / 3 arc-shaped slate 1' The inner arc surface 12' of the inner arc surface 12' is glued and the mesh is reinforced to reinforce it; b. First use a rough grinder to rough grind 1 / 3 of the arc-shaped stone slab 1', and then use a water mill to water grind; c. Grind 1 / 3 The arc-shaped stone slab 1' is placed on the base 3' of the double-knife bridge cutting machine with the inner arc surface 12' facing upwards. The base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com