Production device of powder molding press forming products

A technology of compression molding and production equipment, which is applied in the production equipment of powder compression molding products and non-fiber powder compression molding products, which can solve the problems of inconvenient mold maintenance or replacement, difficult guarantee of processing quality, and high risk of operation. , to achieve the effect of simple structure, less space occupation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

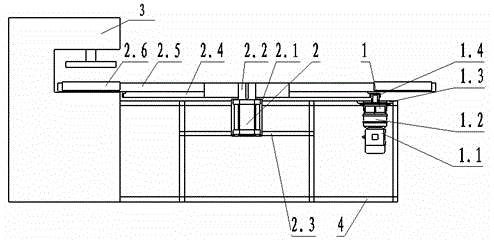

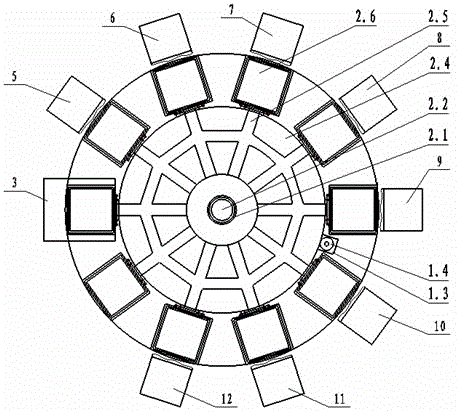

[0012] The production device (abbreviation production device, see figure 1 , 2 ), including frame 4, mold transmission mechanism and sub-equipment. According to the product design process requirements, the number and installation position of sub-equipment correspond to the number of molds and stations on the mold transmission mechanism. The sub-equipment includes separation Mechanism 5, cleaning mechanism 6, loading machine 7, feeding machine 8, and loading machine 9, etc., are characterized in that the mold transmission mechanism adopts a rotary mold circulation transmission mechanism, and the sub-equipment is in order according to the product design process requirements It surrounds each mold station of the rotary mold circulation transmission mechanism, and starts from the stamping station and ends at the product forming station to form a continuous proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com