Composite wheel structure automobile

A wheel and car technology, applied in the direction of wheels, wheels that can support multiple tires, vehicle parts, etc., can solve the problems of energy waste, low efficiency, and high energy consumption of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

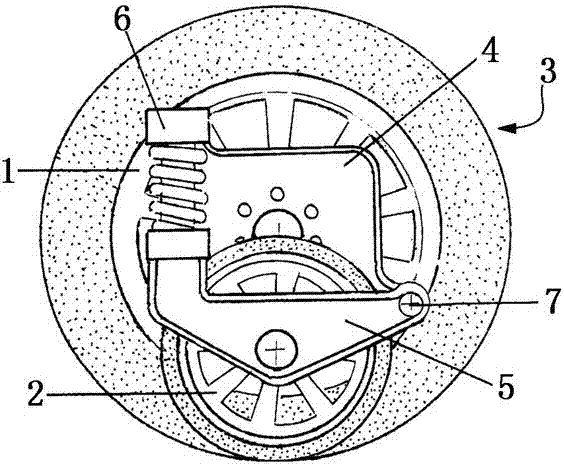

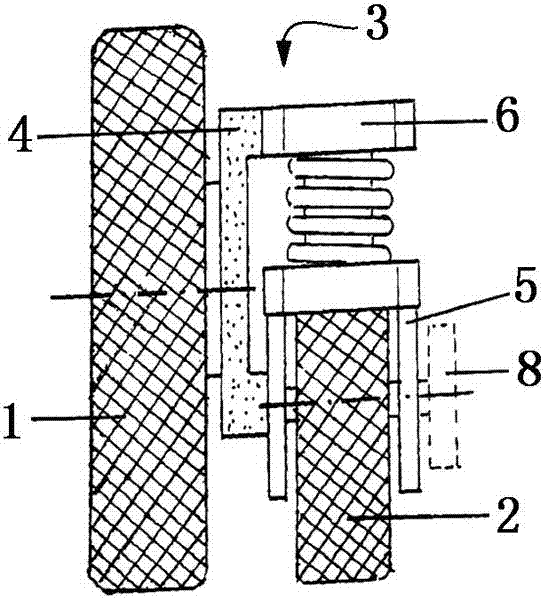

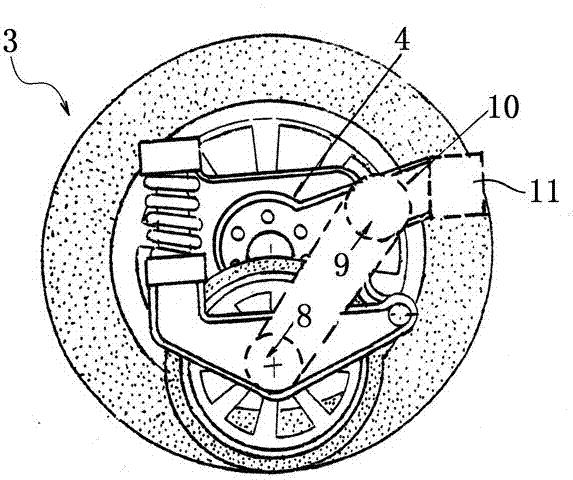

[0027] see figure 1 and figure 2 , the composite wheel 3 is based on the load wheel 1, and the non-load wheel (drive wheel) 2 is auxiliary, and is combined through connecting parts. Its composition is:

[0028] The load wheel 1 is fixed on the connecting bracket 4, and the connecting bracket 4 is connected with the vehicle body to form a stable wheel structure system;

[0029] The non-load wheel (drive wheel) 2 is fixed by the movable bracket 5, one end of the movable bracket 5 is connected to the pressure regulator 6, and the other end of the pressure regulator 6 is connected to the connecting bracket 4; the other end of the movable bracket 5 is fixed on the connecting bracket 4 through the movable joint 7 On the top, a composite overall structure of the non-load wheel (drive wheel) 2 flexibly accompanied by the load wheel 1 is formed;

[0030] The non-load wheel (drive wheel) 2 of the composite wheel 3 is connected with the external power transmission system through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com