Derusting device for engineering mechanical equipment based on spraying mechanism

A technology for construction machinery and equipment, applied in the field of derusting devices for construction machinery and equipment, can solve the problems of reducing the quality of derusting, high pressure, insufficient supply, etc., and achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

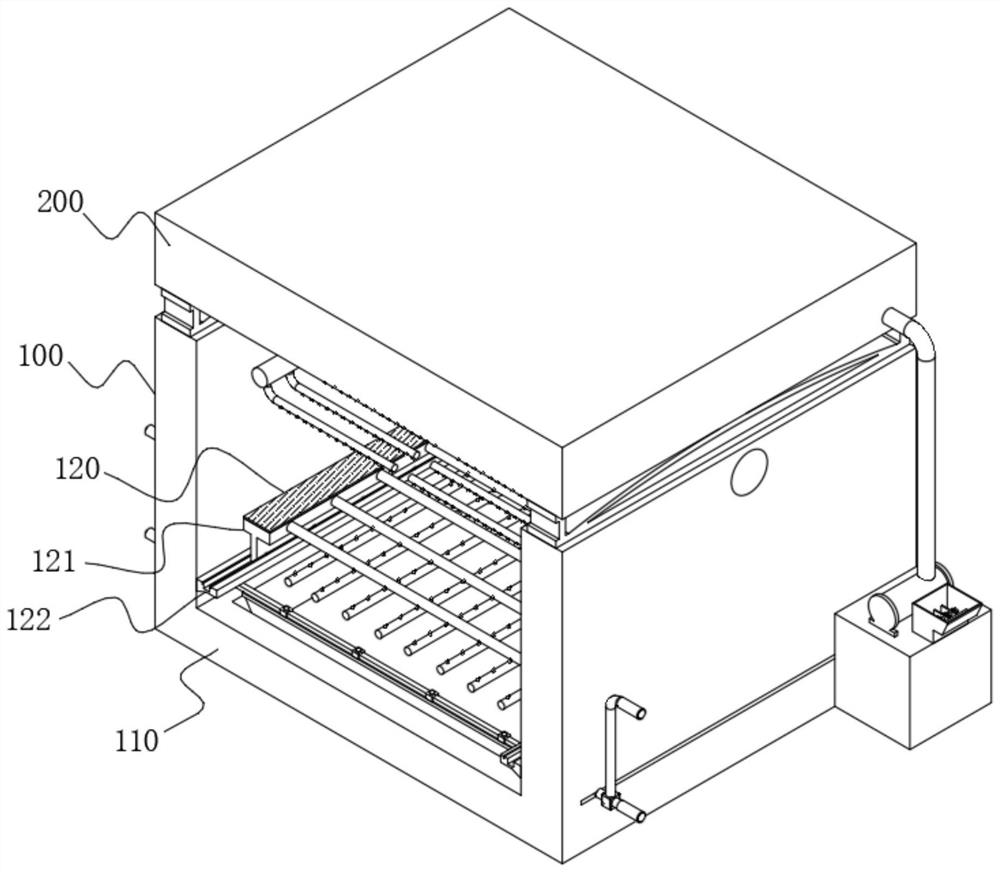

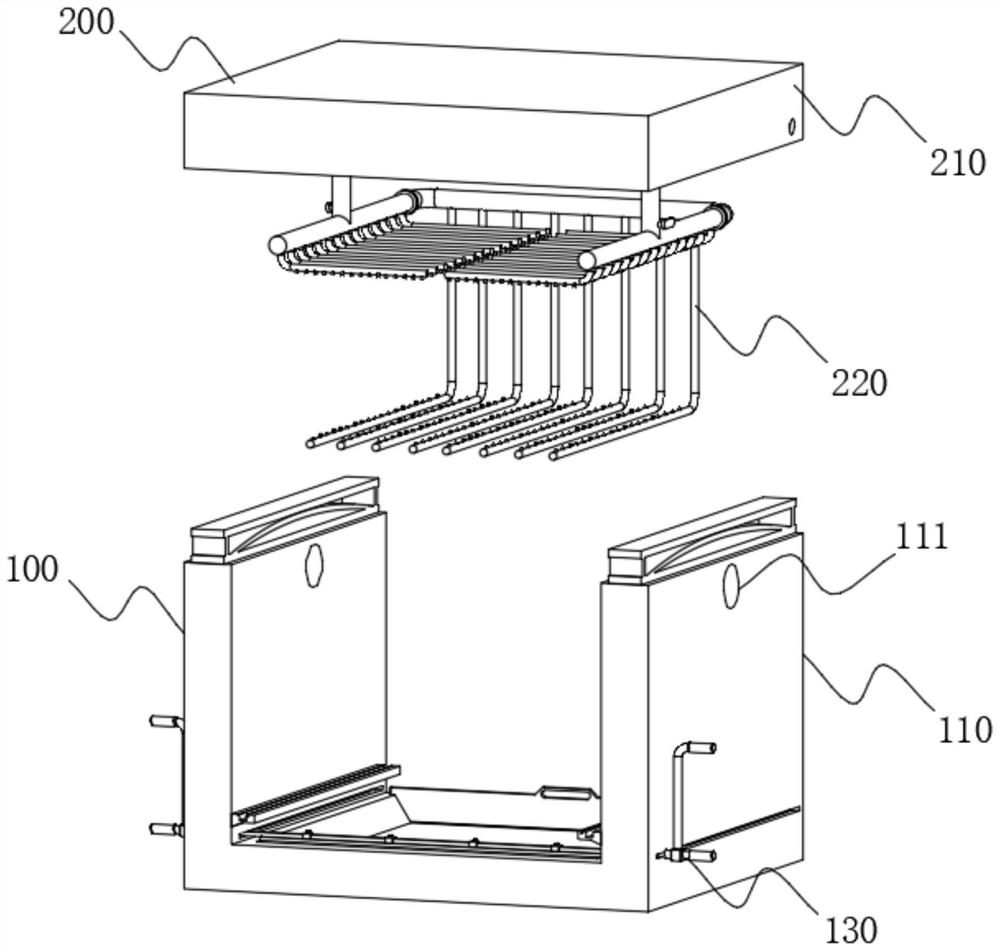

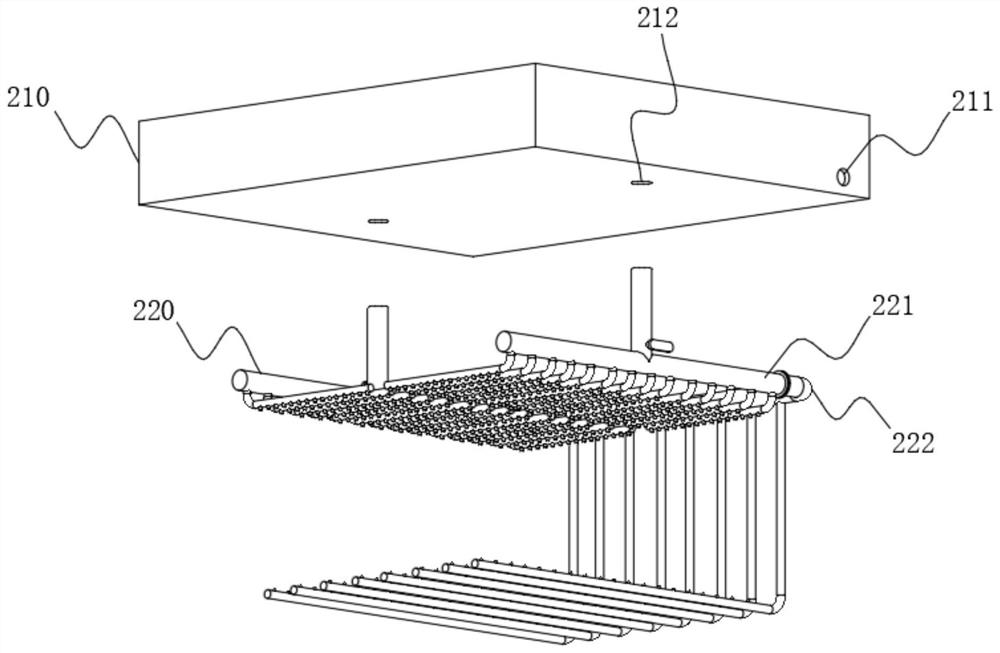

[0072] The invention provides a derusting device for construction machinery equipment based on a spray mechanism, please refer to Figure 1-Figure 19 , including a support device 100 and a spray mechanism 200 arranged on the top of the support device 100, the support device 100 includes a support frame 110, the support frame 110 is a "U"-shaped structure, and a cavity is formed inside the "U"-shaped structure, and the cavity The bottom of the bottom is provided with a support frame 120, the support frame 120 includes a support plate 121, two support plates 121 are provided, and the two support plates 121 are respectively arranged on the left and right sides of the cavity, and the spray mechanism 200 includes at least a spray Box 210, the spray box 210 is a hollow shell, used to store the rust remover, the inside of the spray box 210 is provided with a pressure plate 213, the side walls of the pressure plate 213 are closely attached to the inner wall of the spray box 210, The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com