Lazy arm protruded four-link steel wire rope telescoping mechanism

A telescopic mechanism and wire rope technology, which is applied in the field of engineering hoisting machinery and equipment, can solve the problems of reduced life safety factor of the wire rope, it is difficult for the wire rope to be uniformly stressed, and the movement space is small. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

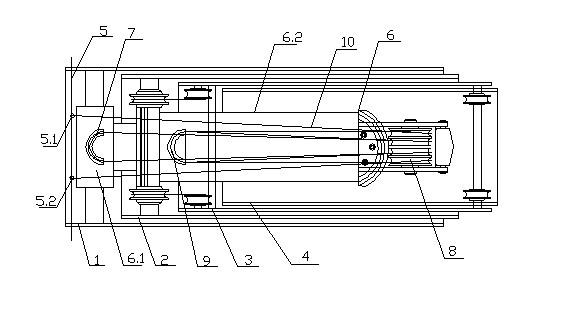

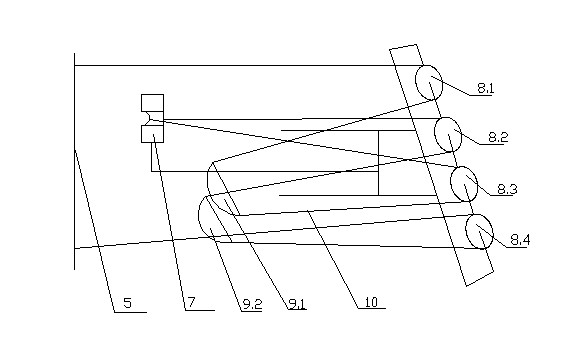

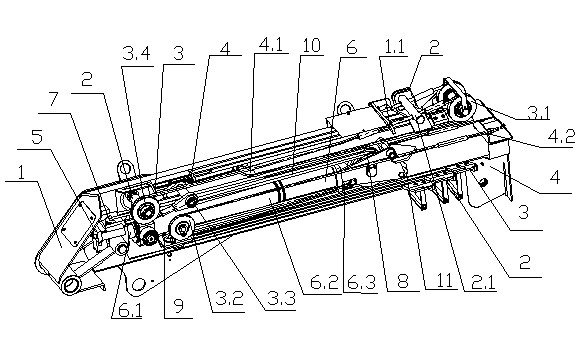

[0010] The technical content of the present invention will be further described in conjunction with the accompanying drawings.

[0011] Such as figure 1 , figure 2 , image 3 As shown, the boom extends out of the quadruple steel wire rope telescopic mechanism, including the big arm 1, the second arm 2, the third arm 3, and the small arm 4. The arms are nested with each other and directly connected by sliders. There is a double wire rope pull plate 5, two holes 5.1, 5.2 for the wire rope to pass through are opened on the double wire rope pull plate 5, the boom head has a boom head fixing hole 1.1 on the head of the boom 1; the piston rod 6.1 of the telescopic oil cylinder 6 Hinged with the big arm 1, the piston rod 6.1 of the telescopic oil cylinder 6 is provided with a piston rod head half-moon pulley 7, and the piston cylinder 6.2 of the telescopic oil cylinder 6 is hinged with the second arm 2; the head of the second arm 2 is fixed by the second arm head Shaft end hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com