Diagnosis method of canister flow

A diagnostic method and technology of carbon canisters, applied in the direction of adding non-fuel substances, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

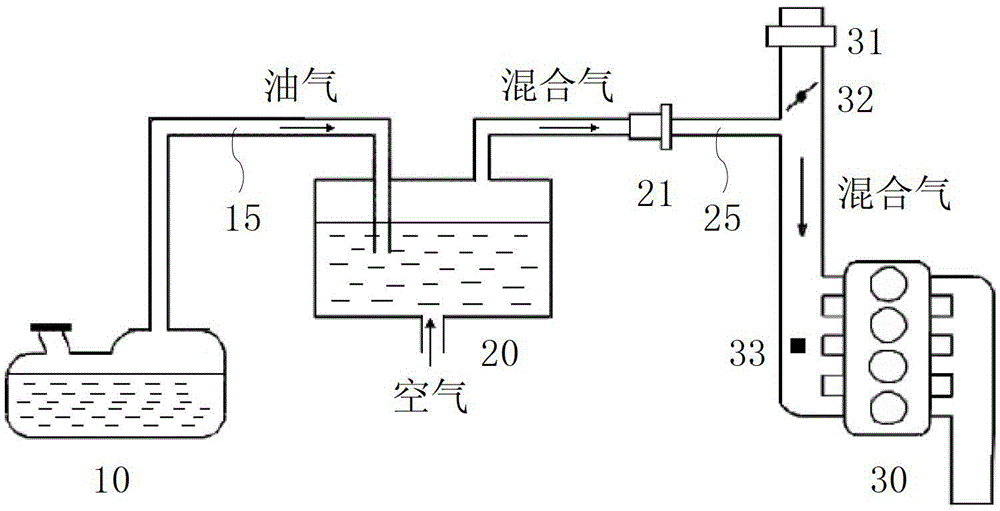

Image

Examples

no. 1 example

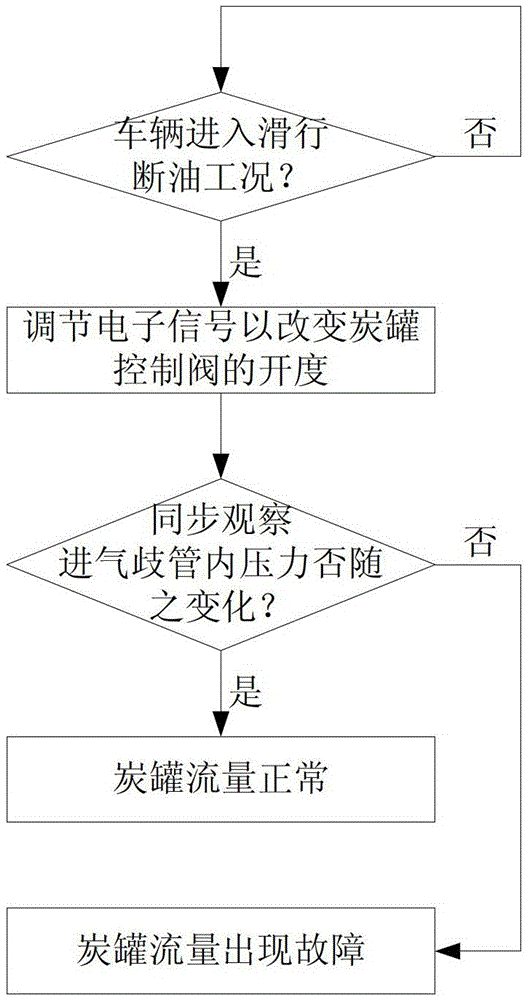

[0029] see figure 2 , the first embodiment of the method for diagnosing the canister flow of the present application includes:

[0030] First, the EMS system waits for the vehicle to enter the coasting fuel cut-off condition. The coasting fuel cut-off condition means that the vehicle satisfies the following three conditions at the same time: the vehicle has a certain speed (>0), the fuel injection device does not inject fuel, and the throttle valve is fully closed.

[0031] Then, the EMS system adjusts the electronic signal controlling the opening of the canister control valve 21 and simultaneously detects the pressure in the intake manifold 30 . Normally, the opening degree of the canister control valve 21 is controlled by electronic signals to change. For example, the electronic signal is a PWM signal, and the opening of the canister control valve 21 is linearly proportional to the duty cycle of the PWM signal. As the duty ratio of the PWM signal increases, the opening o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com