Fault information collection and transmission method of motor control system

A technology of fault information and transmission method, applied in transmission systems, digital transmission systems, electrical components, etc., can solve the problem of large amount of real-time data, many variables of motor control system, timing and reliability of transmission affecting the quality of fault diagnosis system and other problems, to avoid false triggering, improve accuracy, and be easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

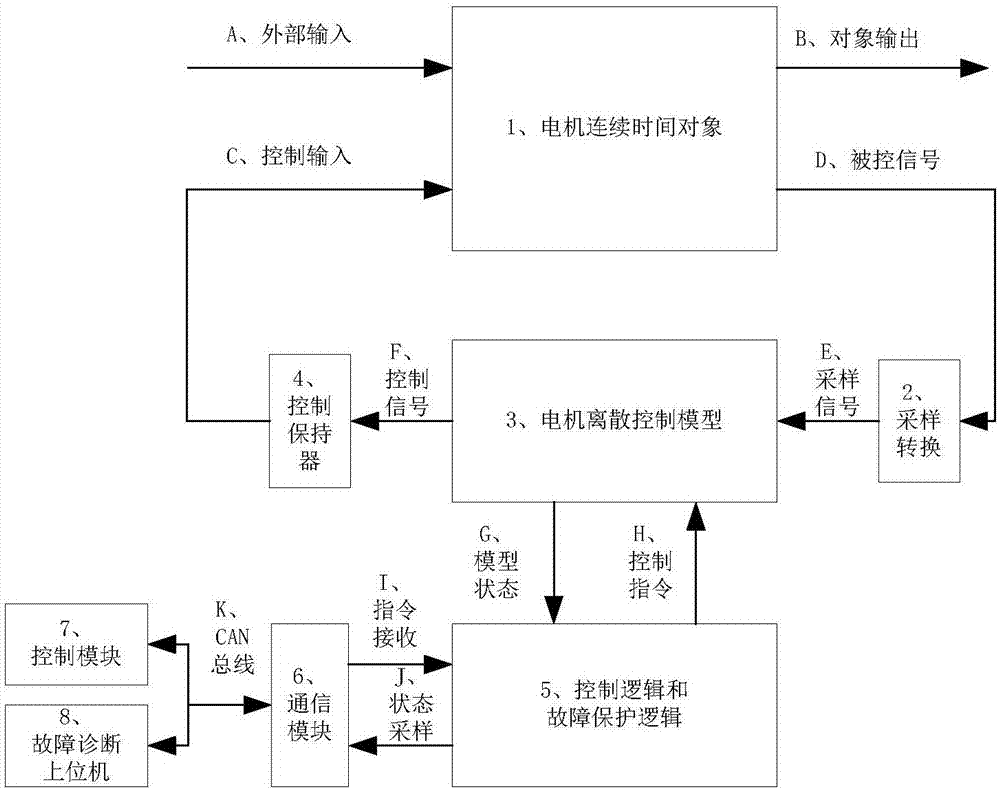

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

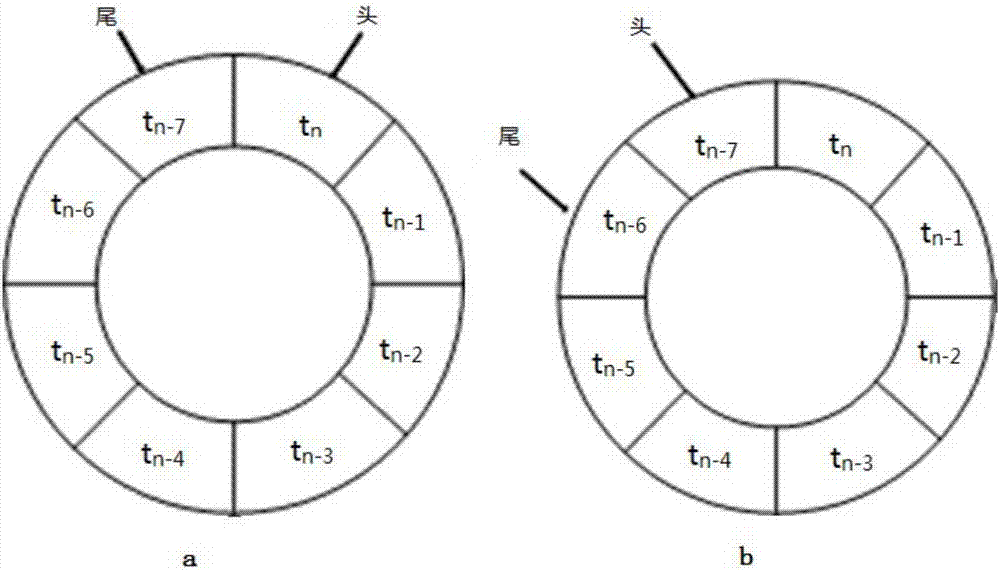

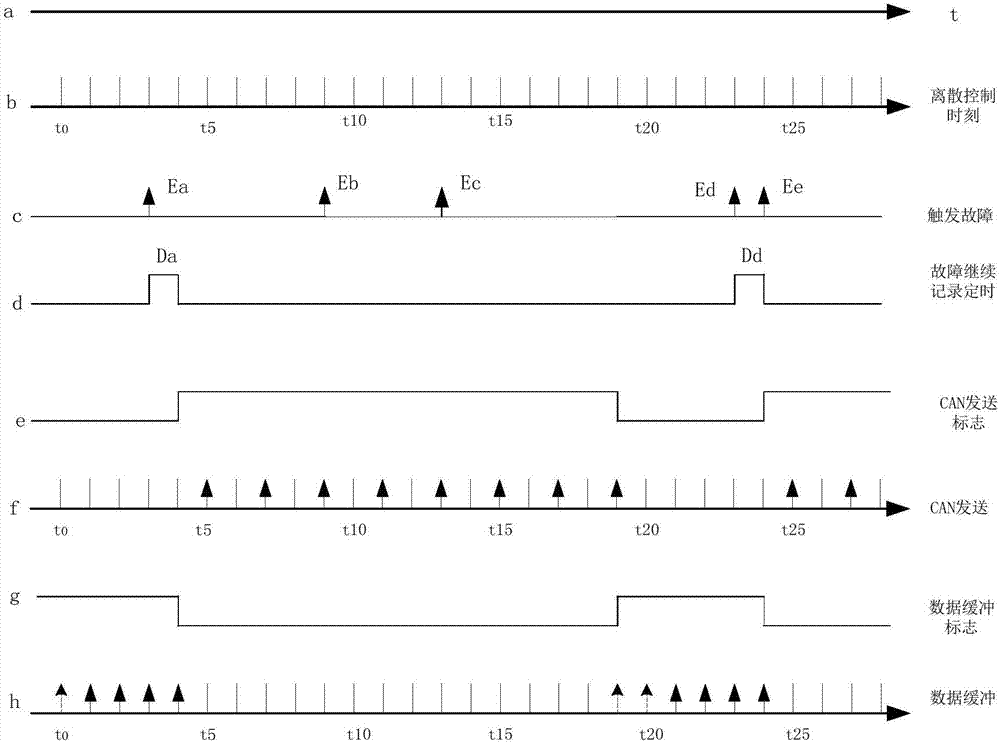

[0042]What needs to be explained in advance is that in the existing technical scheme, take the following as an example: "The control period is between 50us and 500us, if the control period is fixed at 100us, and the monitoring variables (16bit) are recorded as 20, the data generation amount DataSpeed is 3200000bps", which means that the effective information rate of the AC motor control in this example is 3.2Mbps (3200000bps), not including the efficiency loss of the communication protocol (for example, the implementation of the protocol needs to add protocol data such as head, tail, ack and interactive data , so in general, the effective information rate of a 1Mbps CAN network is around 300kbps). Therefore, it can be understood that for the amount of real-time da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com