Novel gas ballast valve

A gas ballast and valve body technology, applied in the field of gas ballast valves, can solve the problems of small occupied space, low cost and high cost, and achieve the effect of reducing occupied space and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

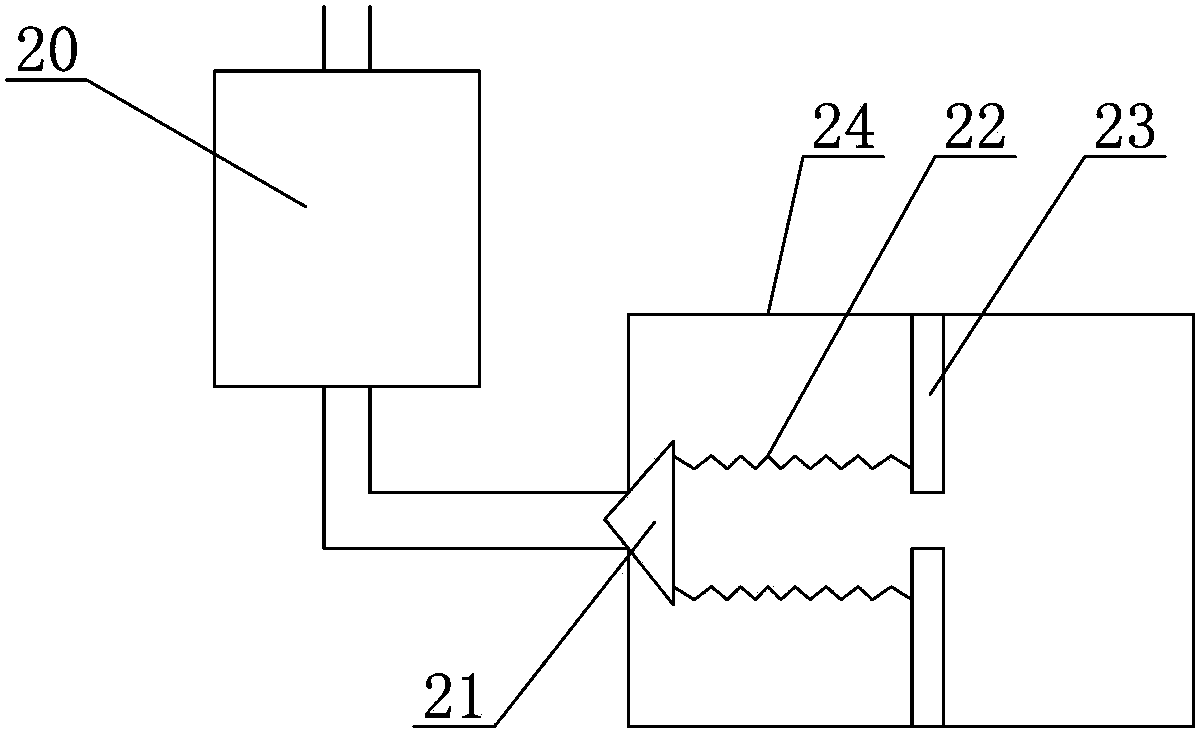

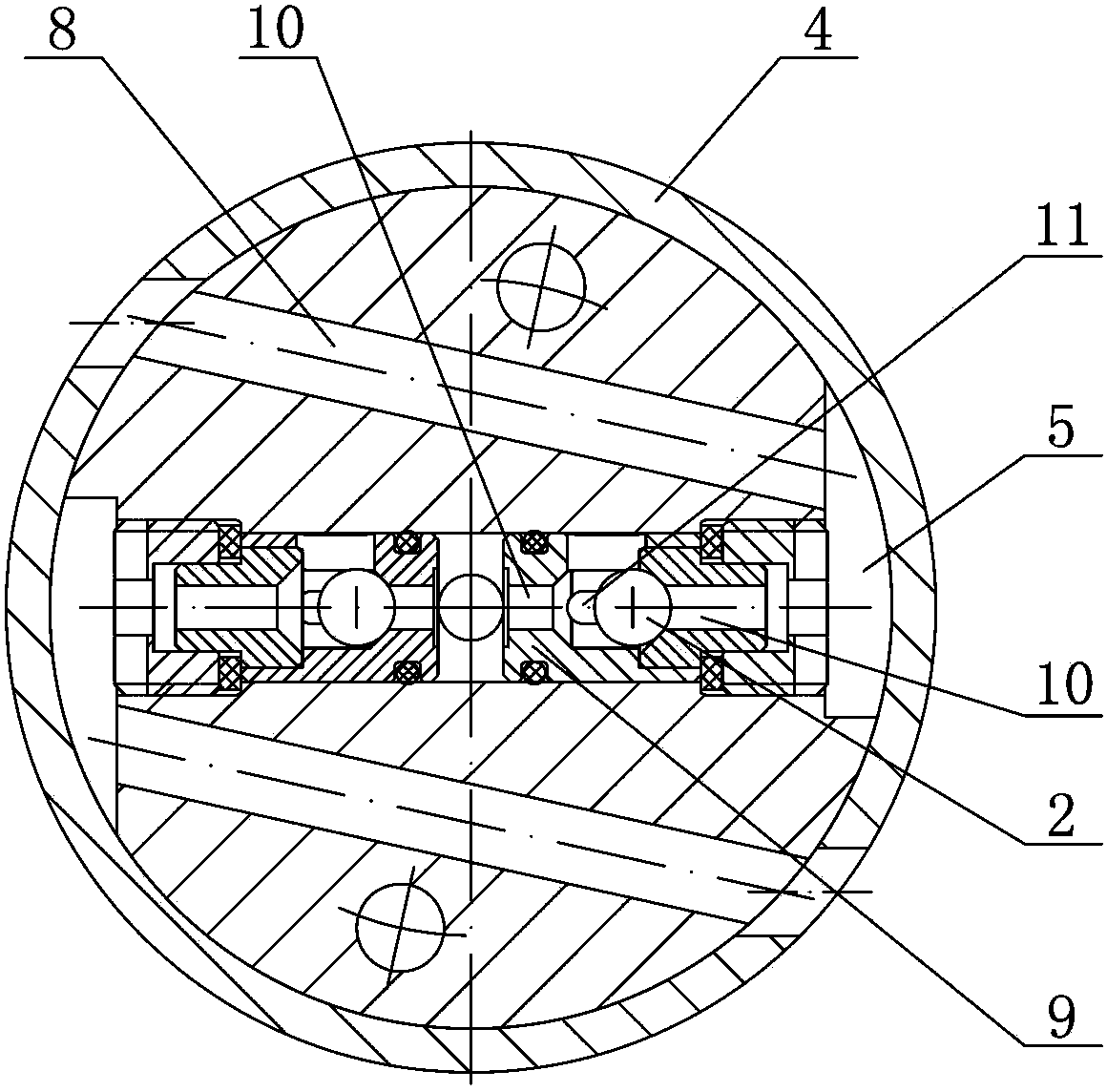

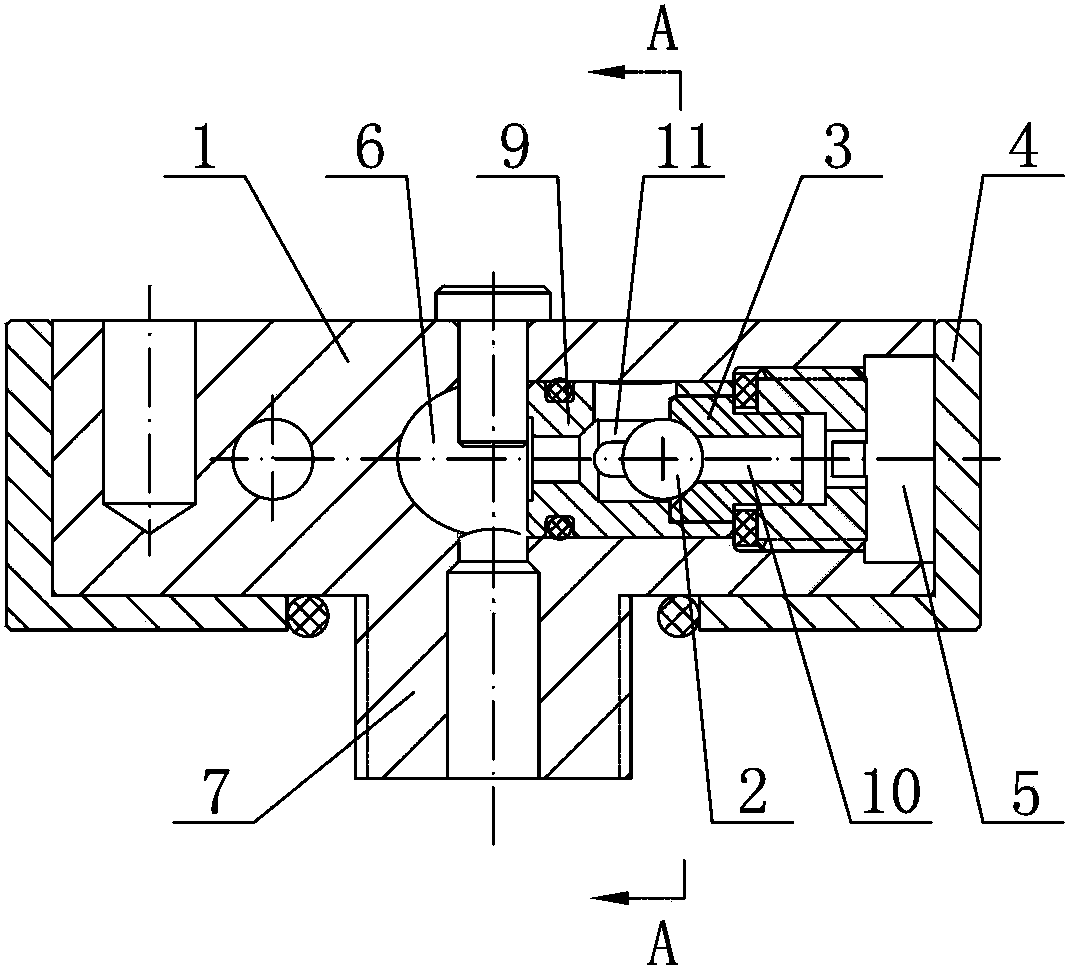

[0021] Such as figure 2 , image 3 and Figure 4 The new gas ballast valve shown is provided with a valve body 1, a steel ball 2, a valve core 3, a retaining sleeve 4, a filter cavity 5, a compression cavity 6, a connecting shaft 7, an external air intake channel 8, a valve sleeve 9, an inner Air intake channel 10, acrosome cavity 11.

[0022] The lower end of the valve body 1 is provided with a connecting shaft 7, and the connecting shaft 7 is provided with threads. At the same time, the working shaft of the centrifugal oil purification equipment connected with the present invention is also provided with threads. These two groups of threads cooperate with each other, so in the centrifugal When the working shaft of the oil purification equipment rotates, the entire gas ballast valve will also rotate with it.

[0023] The upper end of the valve body 1 is a cylinder, and it can also be set as other structures having the same function. The valve body 1 is provided with at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com