Longitudinal dual clutch automatic transmission device with direct gear

An automatic transmission and transmission technology, which is applied to transmissions, gear transmissions, mechanical equipment, etc., can solve the problems of unfavorable vehicle layout, vehicle power, fuel economy, long length of hollow outer input shaft, and heavy transmission weight. , to achieve the effect of light weight, simplified structure of the whole machine and less number of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

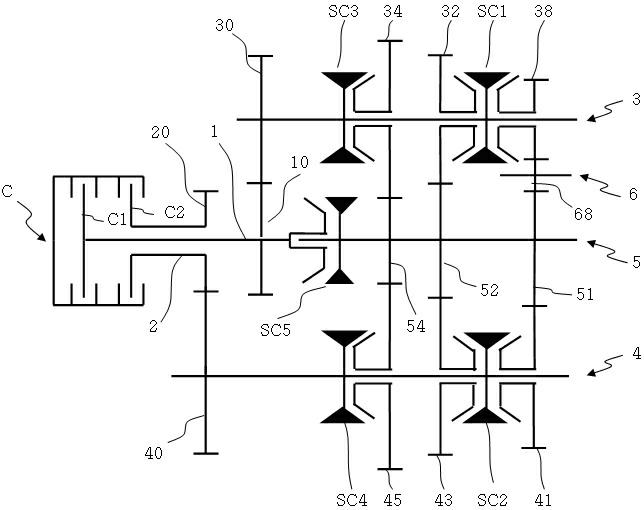

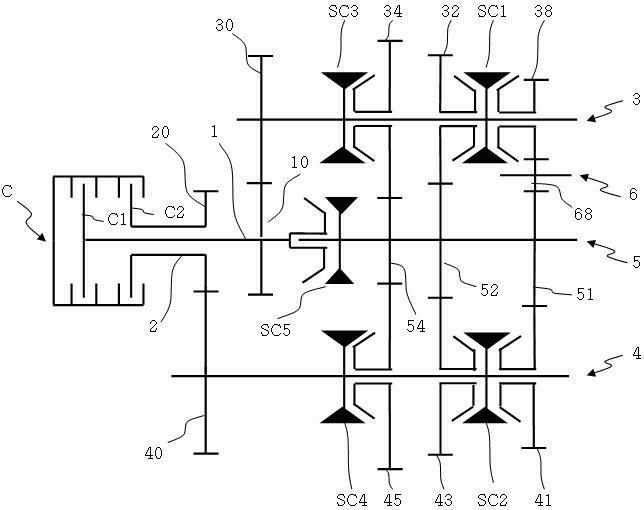

[0016] see figure 1 , the transmission device of the longitudinal dual-clutch automatic transmission with direct gear includes a dual-clutch C, a first input shaft 1 and a second input shaft 2; the dual-clutch C includes a first clutch C1 and a second clutch C2; the second input shaft 2 is Hollow shaft, and the second input shaft gear 20 is provided on the extended end; the first input shaft 1 fixedly connected with the first clutch C1 is located in the input shaft 2 fixedly connected with the second clutch C2, and the first input shaft 1 The first input shaft 1 and the second input shaft 2 are coaxial, and it is characterized in that: the first input shaft 1 is provided with a first input shaft gear 10, and the extended end of the first input shaft 1 is provided with Fifth synchronizer SC5;

[0017] The fifth synchronizer SC5 is connected to the output shaft 5 in an empty sleeve, and the output shaft 5 is coaxial with the first input shaft 1; the output shaft 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com