Phase modulation grating sensor and method for realizing measurement

A grating sensor and phase modulation technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as poor real-time performance, no real-time error measurement compensation module, and limited measurement speed, so as to avoid low-frequency drift and amplitude fluctuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

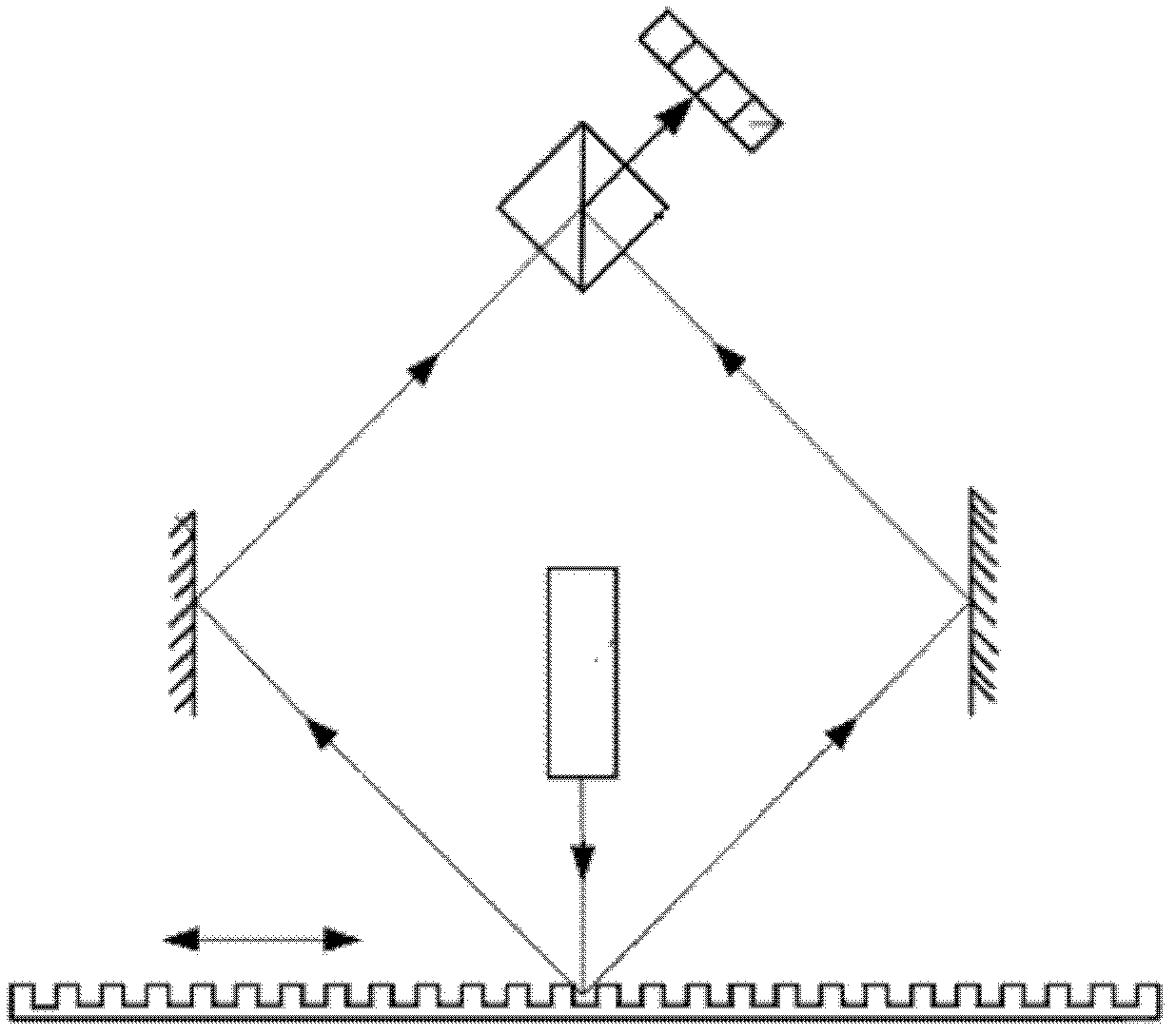

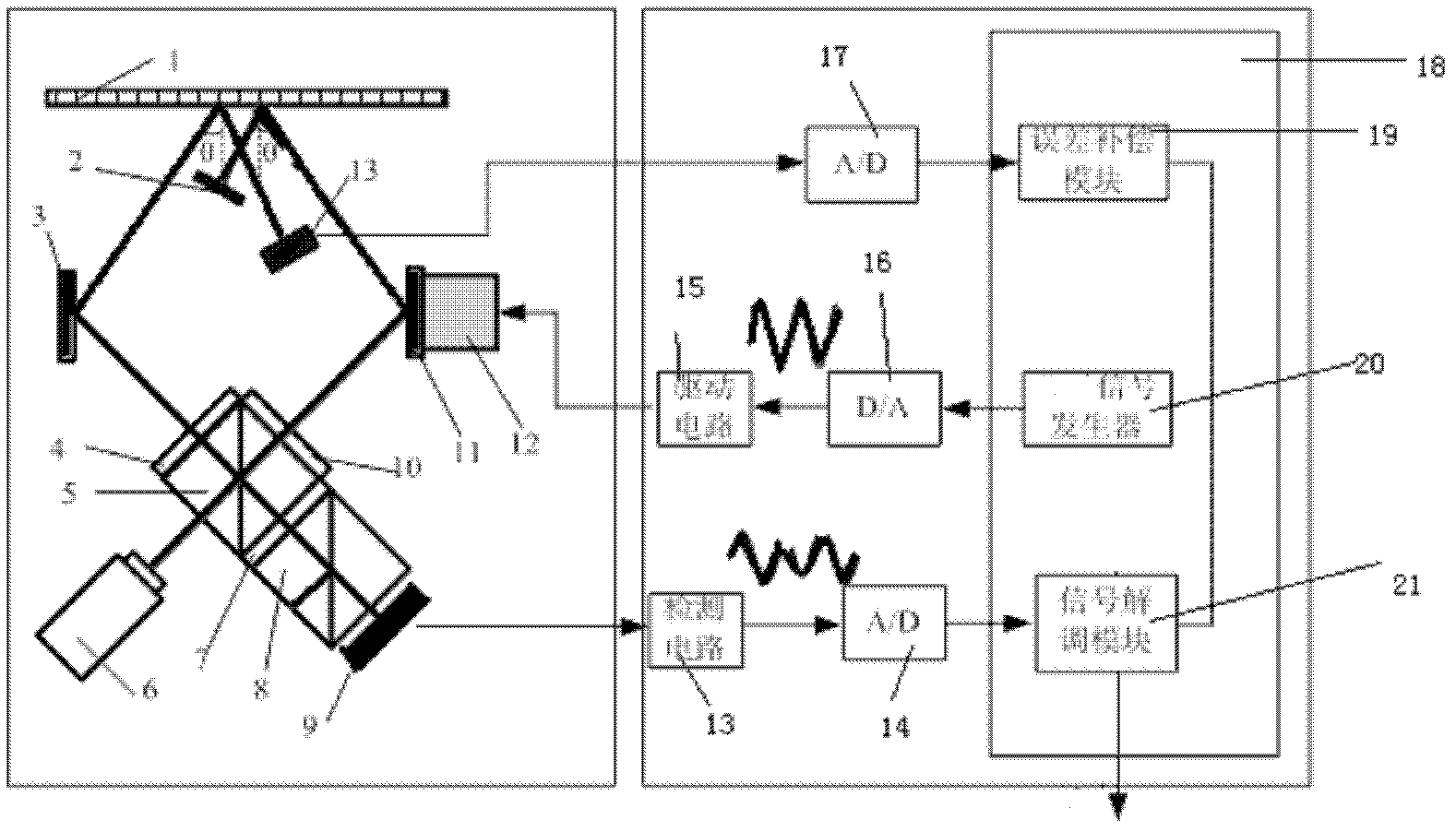

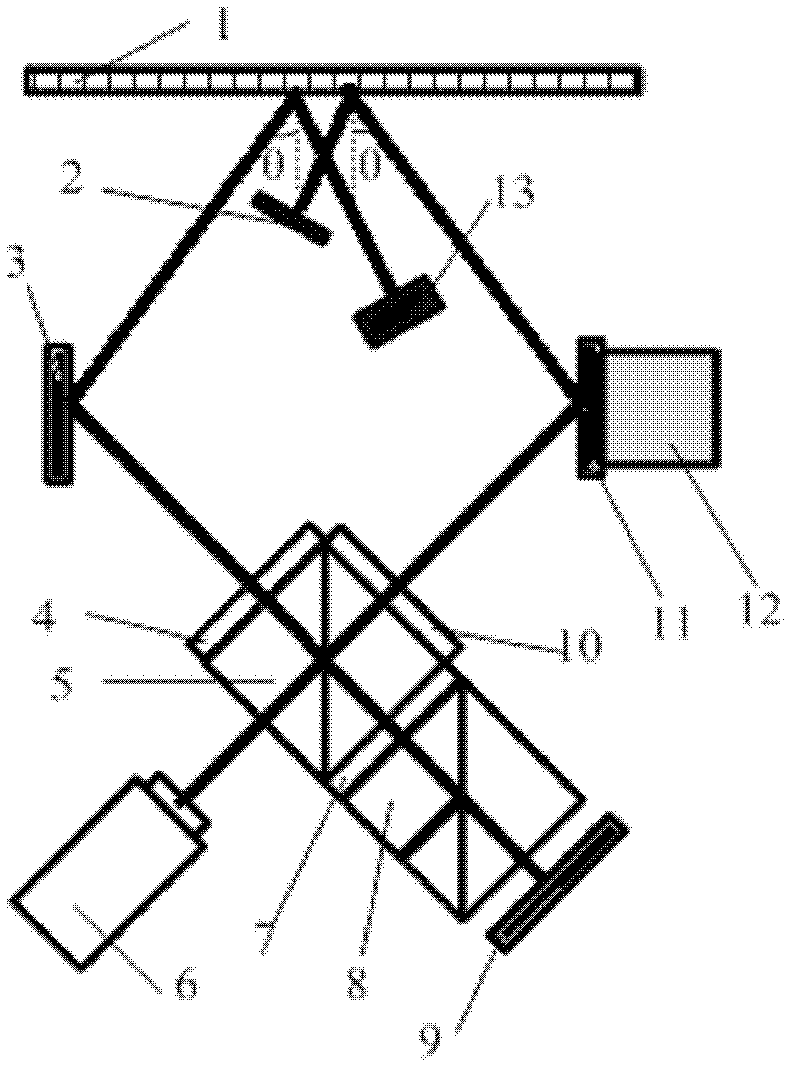

[0060] A phase-modulated grating sensor such as figure 2 As shown, including the optical path part and the signal processing part, the optical path part is as image 3 As shown, it includes reflective grating ruler 1, shading plate 2, two mirrors 3 and 11, three quarter-wave plates 4, 7 and 10, two polarizing beam splitters 5 and 8, semiconductor laser 6, photoelectric Signal detector 9, piezoelectric ceramic actuator 12 and four-quadrant detector 13, the beam-splitting plane of the first polarization beam splitter 5 is facing the light outlet of the semiconductor laser 6, and the three quarter-wave Plates 4, 7 and 10 are respectively placed in front of the symmetrical plane of the splitting plane and two mutually symmetrical planes adjacent to the splitting plane and the fast axes of the three quarter-wave plates 4, 7 and 10 The direction is 45 degrees, the positions of the two mirrors 3 and 11 are symmetrical, and one of the mirrors 11 is pasted on the piezoelectric cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com