Semi-underground large-size horizontal vacuum container for plume test

A vacuum container and large-scale technology, which is applied in the direction of instrumentation, engine testing, machine/structural component testing, etc., can solve the problems of inability to reflect the working conditions of the engine, inconvenient installation and maintenance of instruments and equipment, and unmaintainable dynamic vacuum degree, etc., to achieve Reduce design difficulty, convenient switching, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

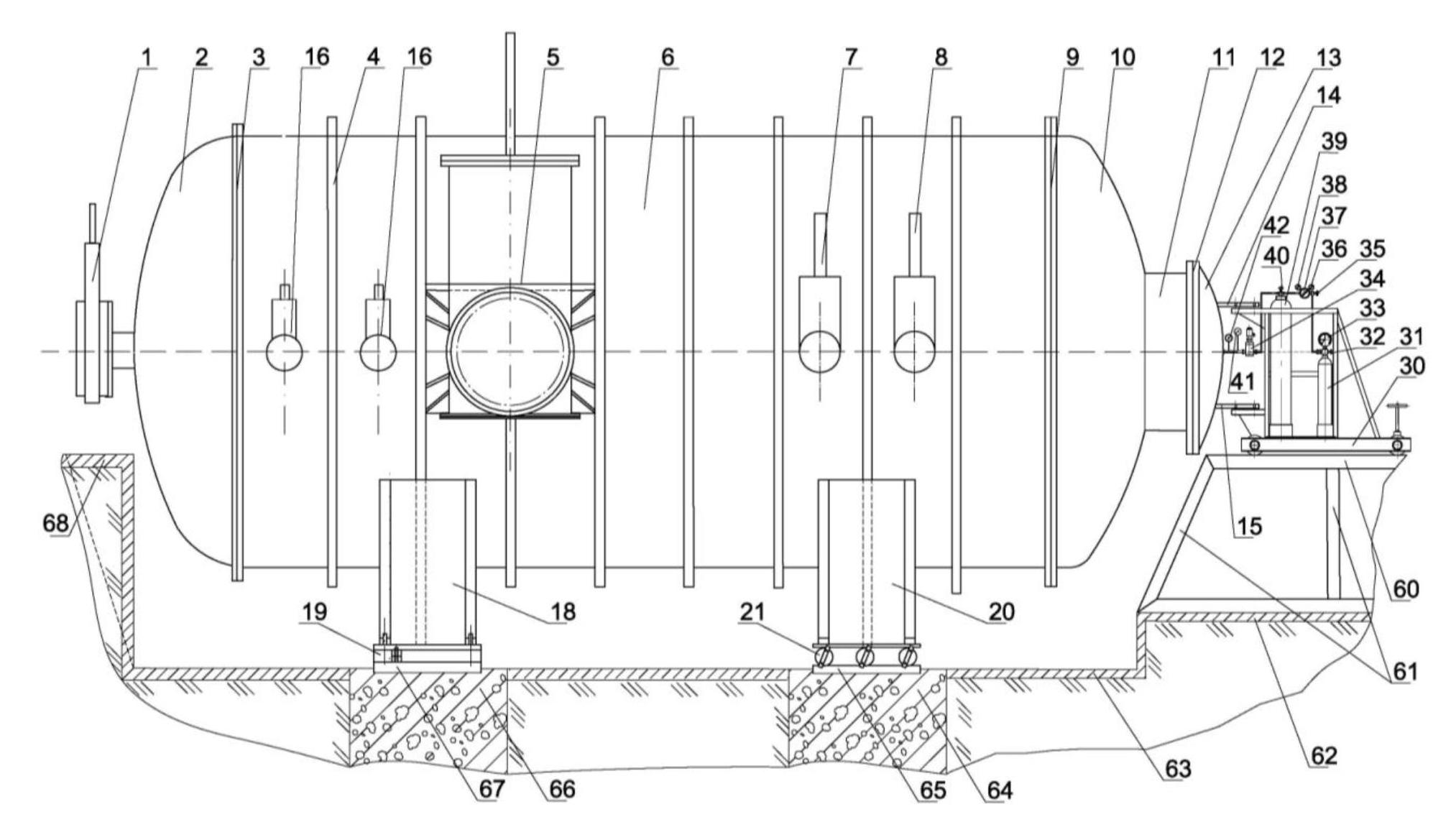

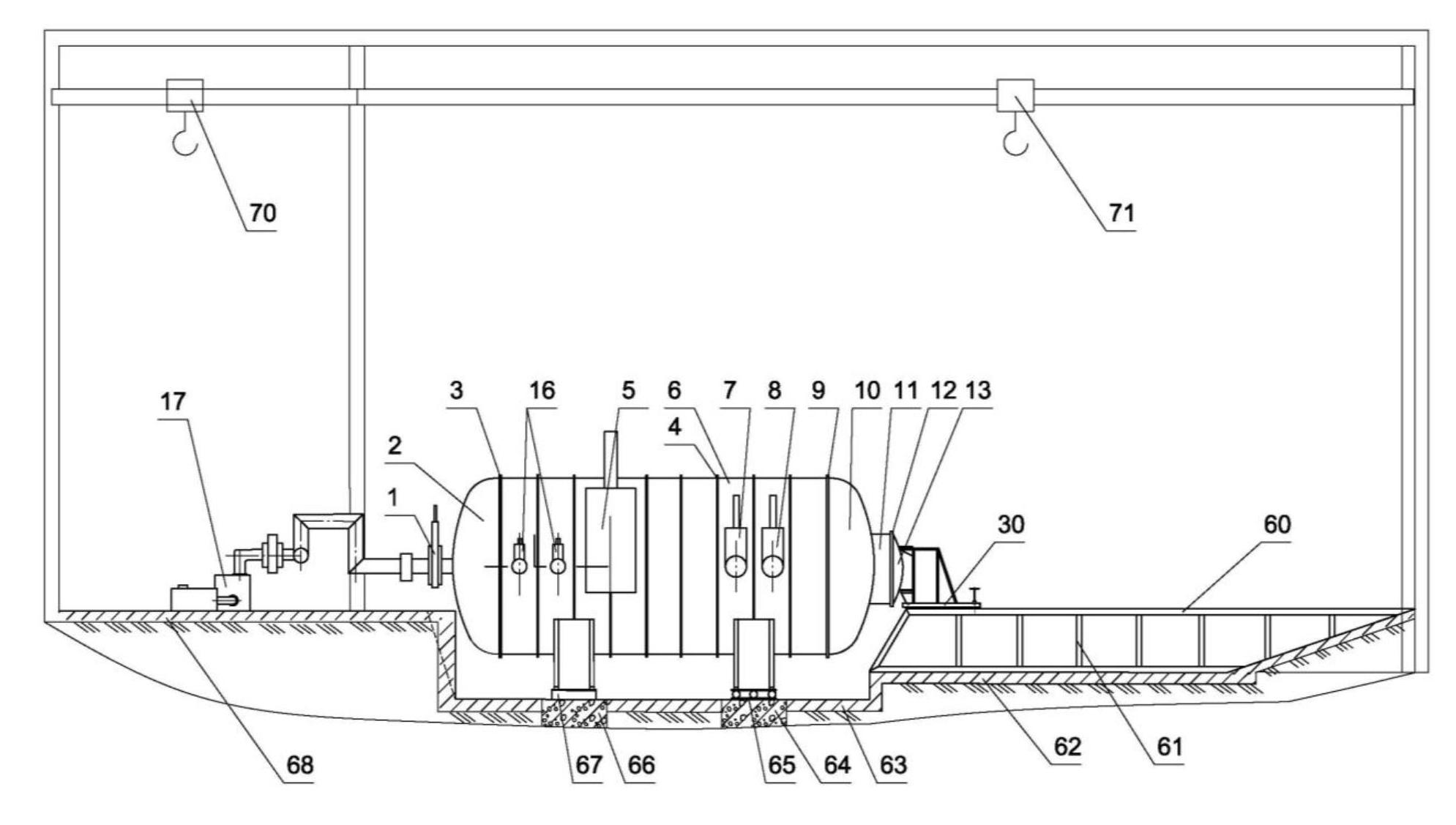

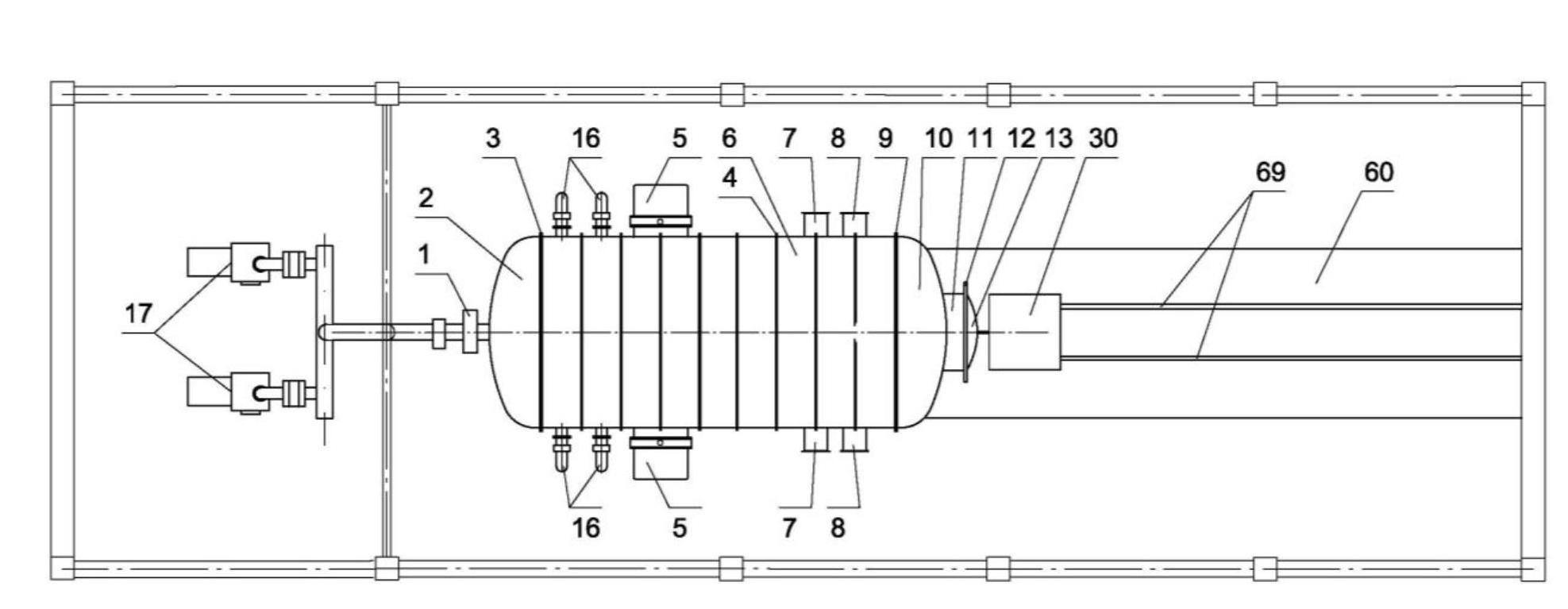

[0049] The present invention proposes a semi-underground large-size horizontal vacuum container for plume test research, such as figure 1 , figure 2 and image 3 As shown, including vacuum container, vacuum acquisition system, propellant supply system and supporting foundation.

[0050] The vacuum container is a semi-underground horizontal structure, providing a vacuum environment for the plume experiment, with a diameter of 6m and a length of 13m; the vacuum acquisition system is used to evacuate the vacuum container to obtain the necessary vacuum environment; the propellant supply system is used to propel Agent storage and supply, providing various propellants for the plume test, using movable trolleys to push and pull, which is convenient for installation during the test and timely push away from the vacuum container after the test; the supporting found...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com